Molybdenum disulfide flexible ion sensor

An ion sensor, molybdenum disulfide technology, applied in the field of MEMS, can solve the problems of affecting long-term stability, increasing noise, submerging effective signals, etc., to achieve the effect of improving long-term stability, improving long-term stability, and avoiding environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention will be further described below in conjunction with the drawings and embodiments.

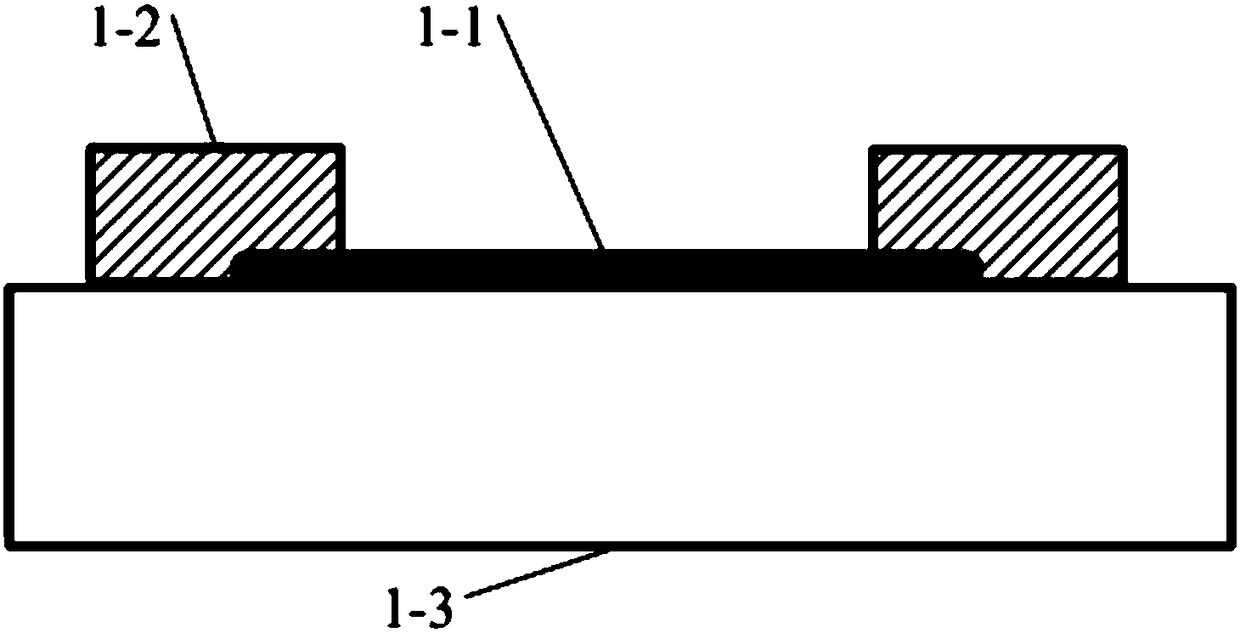

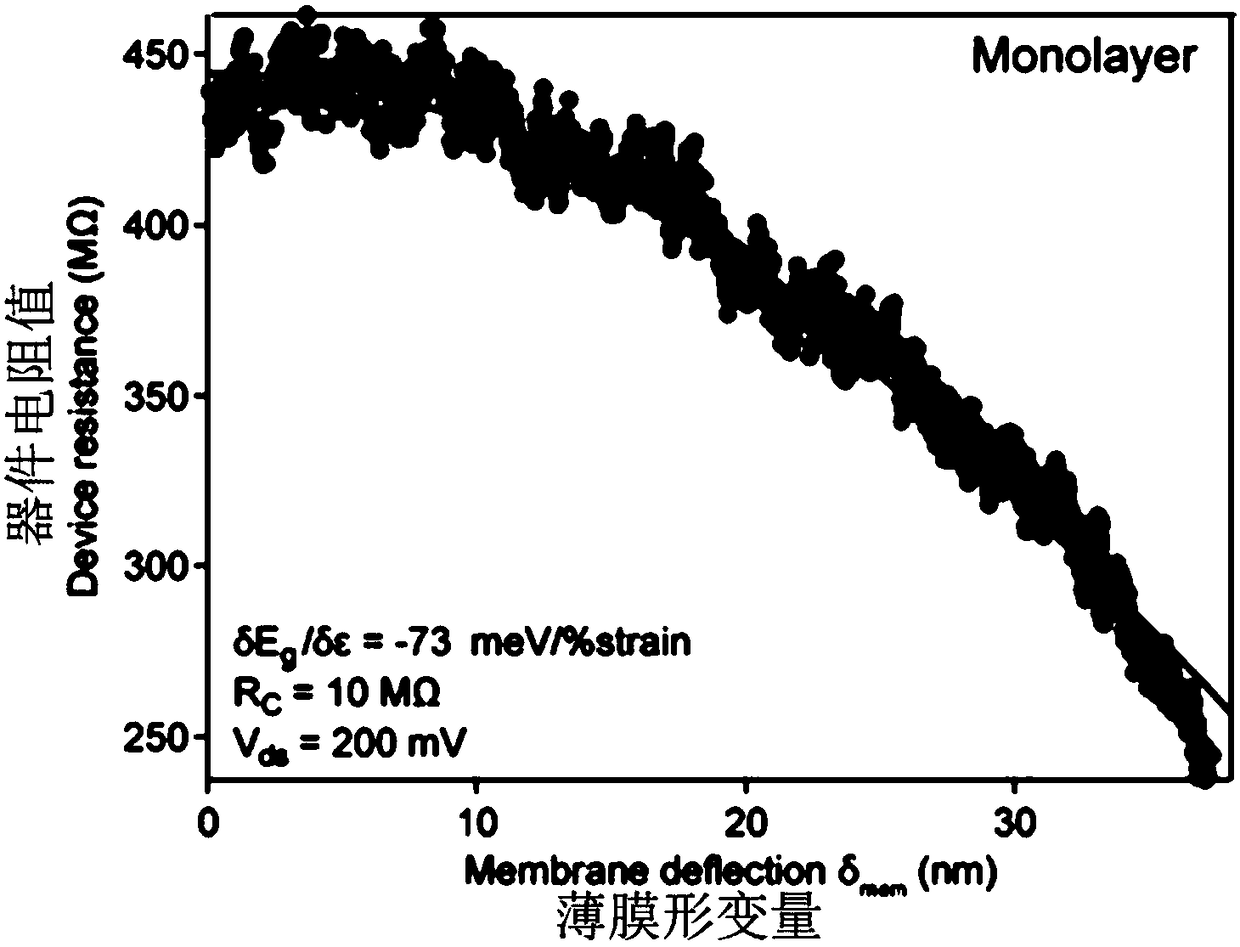

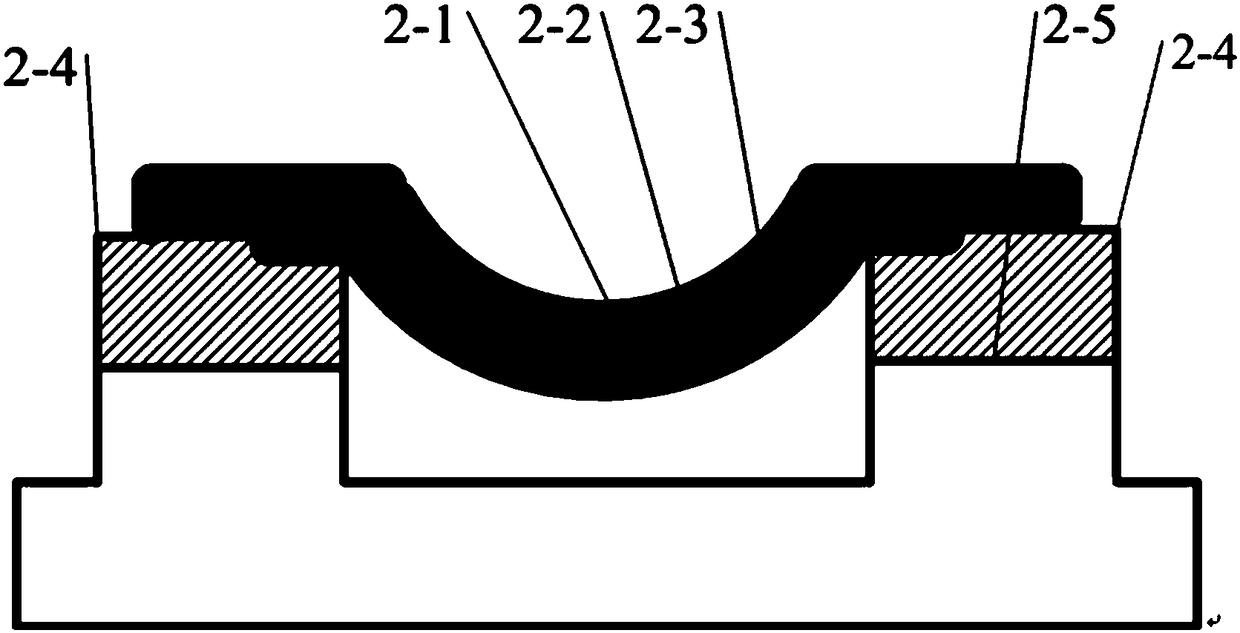

[0025] Reference image 3 , Figure 4 , A molybdenum disulfide flexible ion sensor, characterized in that it comprises a boron nitride layer 2-1, a molybdenum disulfide layer 2-2, a boron nitride layer 2-3, and a metal electrode 2 connected together from top to bottom. -4 and the flexible substrate 2-5; the molybdenum disulfide layer 2-2 is located below the boron nitride layer 2-1 and above the boron nitride layer 2-3, and the molybdenum disulfide layer 2-2 and the boron nitride The layer 2-1 and the boron nitride layer 2-3 constitute a composite beam structure, the two ends of the composite beam are respectively connected with the metal electrodes 2-4, and the middle part of the composite beam is suspended; the flexible substrate 2-5 is located in the suspension of the composite beam structure Part below.

[0026] The molybdenum disulfide layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com