Back-to-back type non-electrolytic capacitor frequency conversion speed regulation system and method

A frequency conversion speed regulation, electrolytic capacitor technology, applied in the control system, electrical components, AC motor control and other directions, can solve the problem that the power adjustment of the inverter circuit cannot fully meet the current control requirements of the grid, to suppress the voltage harmonic content, realize the Dynamic balance and decoupling control, the effect of improving power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

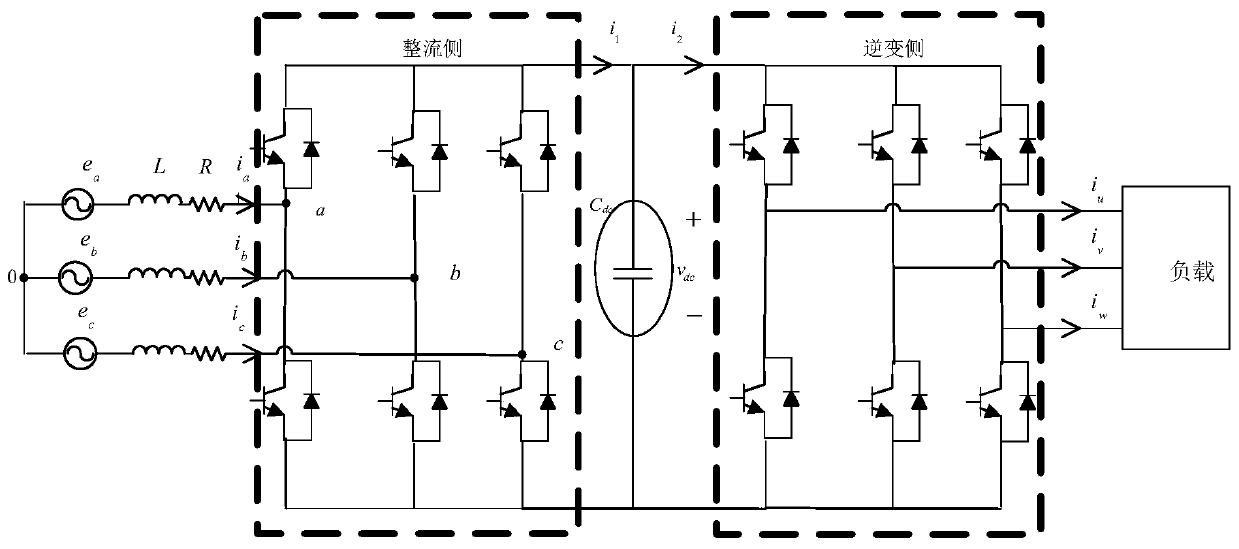

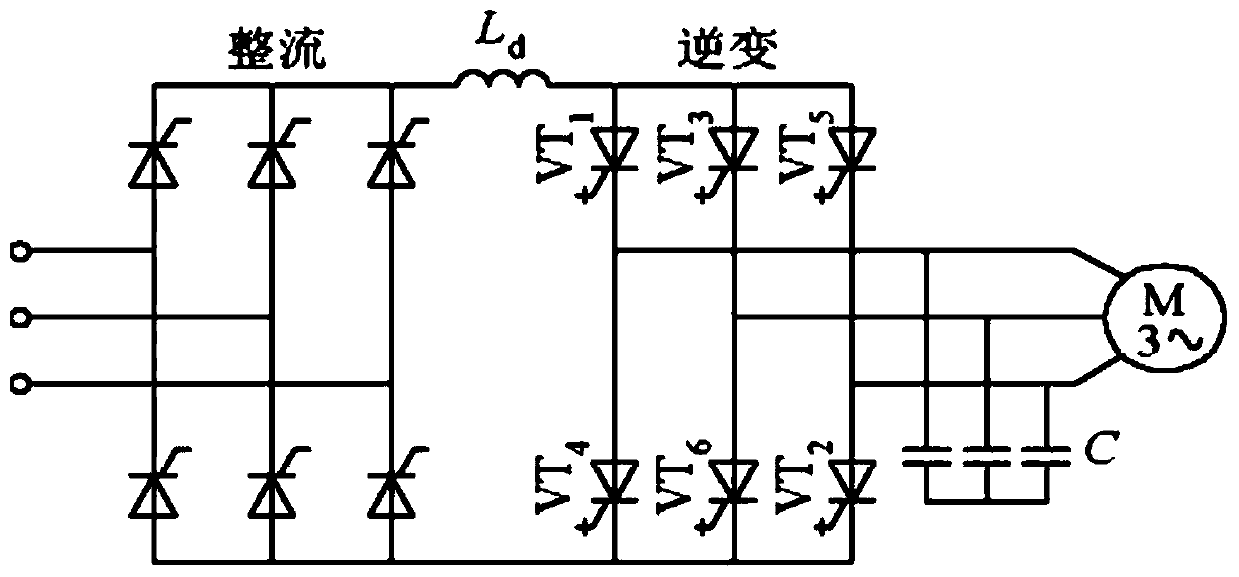

[0035] The present invention proposes a back-to-back non-electrolytic capacitor frequency conversion speed regulation system, including: a rectification link, a DC bus link and an inverter link, and a PTC controller that performs power tracking on both sides of the DC bus to achieve power balance. The link and the inverter link are respectively located on both sides of the DC bus link, and the rectification link includes a small-capacity film capacitor for absorbing high-frequency ripple.

[0036] The invention improves the traditional rectification and inverter control method, proposes the concept and structure of power integration, and proposes a power controller. The power balance on both sides of the DC bus is achieved through power tracking, so as to realize the rapid response to the flowing energy and reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com