Active oxygen preparation and fine control integrated device for upgrading and reforming sewage treatment plant

A sewage treatment plant, upgrading technology, applied in water/sewage treatment equipment, water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

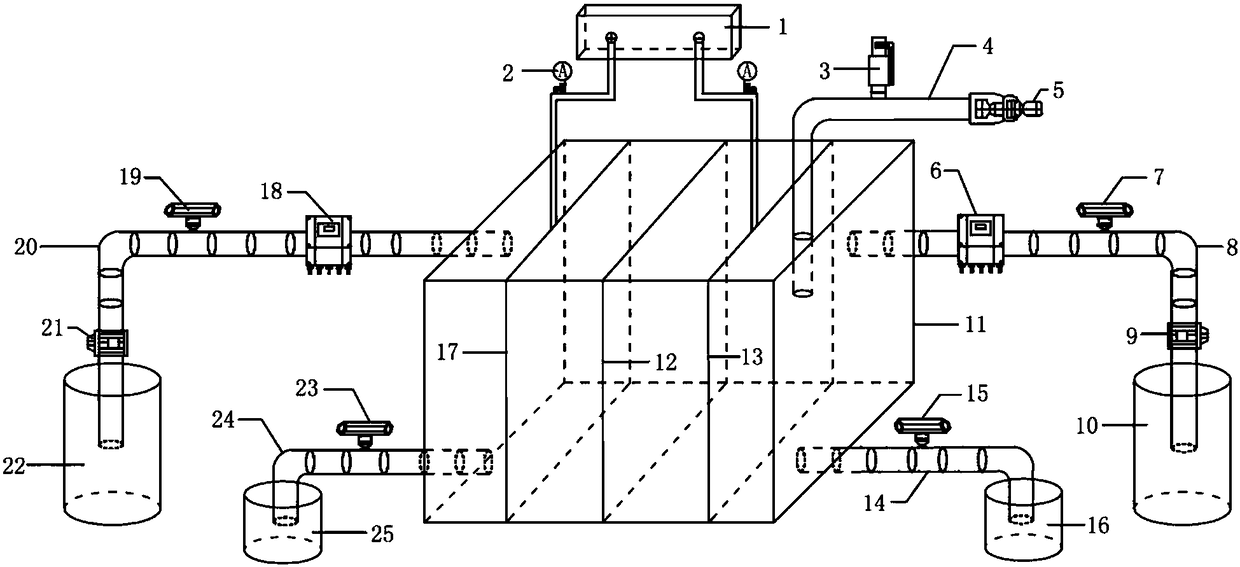

[0085] (1) The preparation process of the active oxygen preparation and fine control integrated device for the upgrading and transformation of sewage treatment plants is as follows:

[0086] The electrolytic cell 11 is a cuboid made of glass plates of polyethylene material, and its length is 50 cm, wide 20 cm, and high 30 cm; the modified cathode plate 13, which is used to prepare active oxygen with a length of 30 cm and a width of 20 cm, is housed in the cell body. A modified anode plate 17 and a Naflon diaphragm 12 for preparing active oxygen; the electrolyte water inlet storage tank 22 is a cylinder with a diameter of 15 cm and a height of 20 cm, and the electrolyte water outlet storage tank 25 is a cylinder with a diameter of 10 cm and a height of 15 cm. The water storage tank 10 is a cylinder with a diameter of 15 cm and a height of 20 cm, and the active oxygen storage tank 16 is a cylinder with a diameter of 10 cm and a height of 15 cm. The air inlet pipe 4, the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com