Device and method for producing potassium peroxymonosulfate composite salt based on jet reactor

A technology of potassium hydrogen peroxymonosulfate composite salt and jet reactor, which is applied in the chemical industry, can solve the problems of increased energy consumption, high energy consumption, long reaction period, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

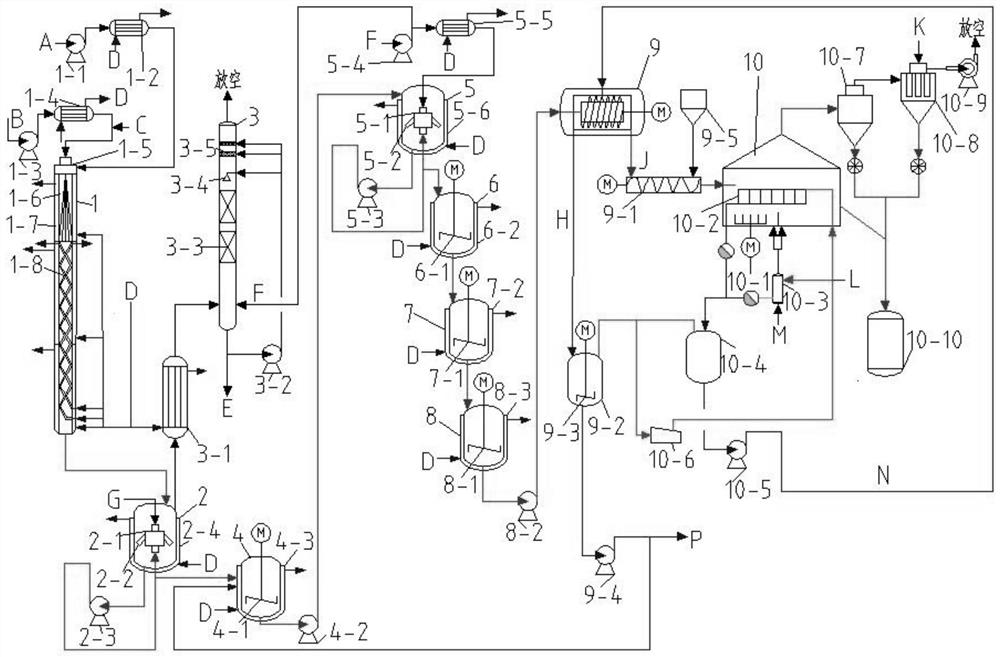

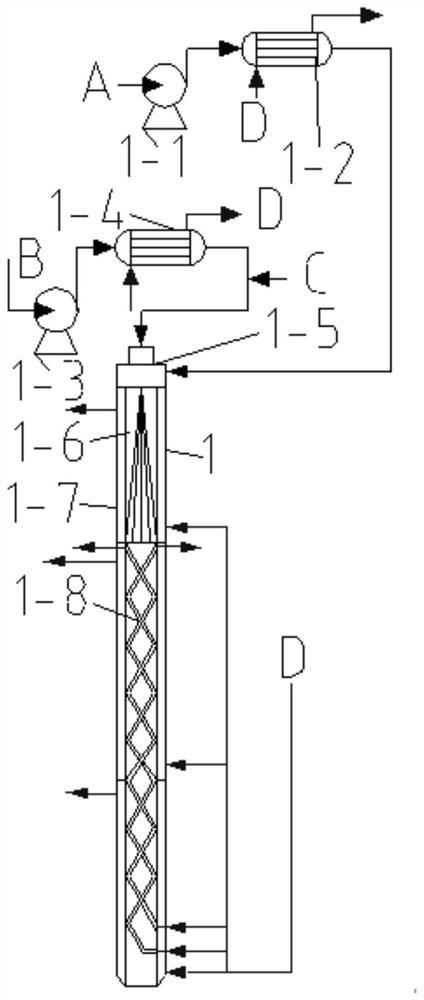

[0042] The production plant of potassium hydrogen persulfate compound salt based on jet reactor, its structural schematic diagram is as follows figure 1 As shown, the schematic diagram of the partial structure of the jet tube oxidation reactor 1 is as follows figure 2 As shown, it includes sequentially connected jet tube oxidation reactor 1, jet supplementary oxidation reactor 2, acid gas absorption tower 3, mixing tank 4, jet neutralization reactor 5, crystallizer I6, crystallizer II7, and crystal slurry tank 8, horizontal double-drum centrifuge 9, fluidized bed drier 10; Described jet tube type oxidation reactor 1 is used for hydrogen peroxide oxidizing concentrated sulfuric acid to generate peroxymonosulfuric acid (H 2 SO 5 ); The jet supplemental oxidation reactor 2 is used for ozone supplementary oxidation concentrated sulfuric acid to generate peroxymonosulfuric acid (H 2 SO 5 ); the acid gas absorption tower 3 is used for absorbing the acid gas produced in the oxida...

Embodiment 2

[0060] The potassium hydrogen persulfate compound salt production method based on the jet reactor based on the device described in embodiment 1 may further comprise the steps:

[0061] Described step (1) 123kg / h raw material concentrated sulfuric acid (mass content 98%) enters the concentrated sulfuric acid cooler 1-2 through concentrated sulfuric acid pump 1-1 and cools, and 84kg / h raw material hydrogen peroxide (mass content 50%) passes hydrogen peroxide pump 1-3 enter the hydrogen peroxide cooler 1-4 for cooling, and the cooled hydrogen peroxide is added with a stabilizer; the cooled concentrated sulfuric acid, cooled hydrogen peroxide, and stabilizer enter the coupler 1-5 of the jet tube oxidation reactor 1 , through the jet flow of the jet device 1-6, the oxidation reaction is carried out under the cooling of the cooling jacket 1-7 and the cooling spoiler element 1-8 of the tubular oxidation reactor; the oxidation liquid enters the jet flow supplementary oxidation reactor ...

Embodiment 3

[0072] The potassium hydrogen persulfate compound salt production method based on the jet reactor based on the device described in embodiment 1 may further comprise the steps:

[0073] Described step (1) 123kg / h raw material concentrated sulfuric acid (mass content 98%) enters the concentrated sulfuric acid cooler 1-2 through concentrated sulfuric acid pump 1-1 and cools, and 84kg / h raw material hydrogen peroxide (mass content 50%) passes hydrogen peroxide pump 1-3 enter the hydrogen peroxide cooler 1-4 for cooling, and the cooled hydrogen peroxide is added with a stabilizer; the cooled concentrated sulfuric acid, cooled hydrogen peroxide, and stabilizer enter the coupler 1-5 of the jet tube oxidation reactor 1 , through the jet flow of the jet device 1-6, the oxidation reaction is carried out under the cooling of the cooling jacket 1-7 and the cooling spoiler element 1-8 of the tubular oxidation reactor; the oxidation liquid enters the jet flow supplementary oxidation reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com