Degradable high-barrier composite material and preparation method thereof

A composite material and high-barrier technology, which is applied in the field of high-barrier composite materials and its preparation, can solve the problems of non-degradable waste, consumption of petroleum resources, and pollution discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

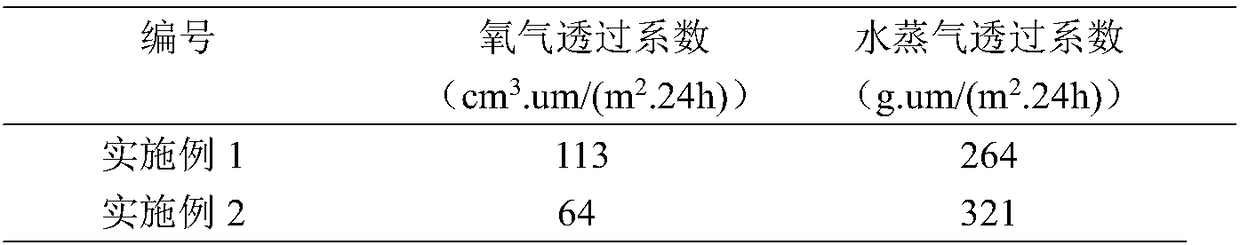

Embodiment 1

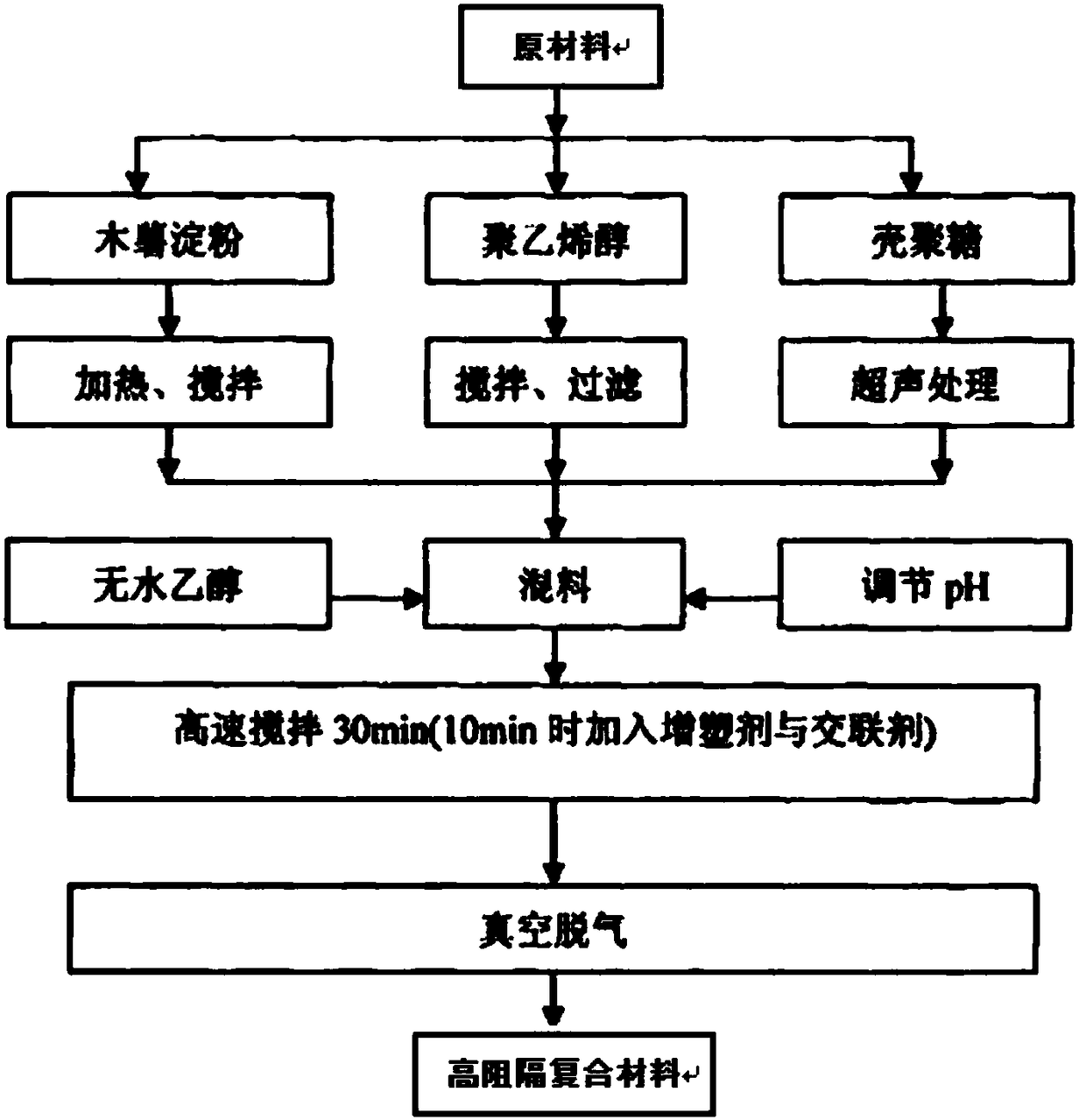

[0026] A degradable high-barrier composite material and a preparation method thereof, the composite material comprising the following steps:

[0027] (1) Preparation of the solution:

[0028] Tapioca starch solution: Dissolve 6.0 grams of tapioca starch in 100ml of distilled water, keep stirring in a water bath at 80°C for 30 minutes, and obtain a tapioca starch solution;

[0029] Polyvinyl alcohol solution: Dissolve 9.0 grams of polyvinyl alcohol in 100ml of distilled water, maintain it in a water bath at 95°C and stir for 30 minutes to obtain a polyvinyl alcohol solution;

[0030] Chitosan solution: Dissolve 3.0 grams of chitosan in 100 ml of 5% acetic acid solution, and ultrasonically disperse in an ultrasonic cleaner for 30 minutes to obtain a chitosan solution.

[0031] (2) Tapioca starch / polyvinyl alcohol / chitosan thin composite material preparation:

[0032] Add the above polyvinyl alcohol solution and chitosan solution into the tapioca starch solution, and add 10mL a...

Embodiment 2

[0034] A degradable high-barrier composite material and a preparation method thereof, the composite material comprising the following steps:

[0035] (1) Preparation of the solution:

[0036] Tapioca starch solution: Dissolve 6.0 grams of tapioca starch in 100ml of distilled water, keep stirring in a water bath at 80°C for 30 minutes, and obtain a tapioca starch solution;

[0037] Polyvinyl alcohol solution: Dissolve 9.0 grams of polyvinyl alcohol in 100ml of distilled water, maintain it in a water bath at 95°C and stir for 30 minutes to obtain a polyvinyl alcohol solution;

[0038] Chitosan solution: Dissolve 3.0 grams of chitosan in 100 ml of 5% acetic acid solution, and ultrasonically disperse in an ultrasonic cleaner for 30 minutes to obtain a chitosan solution.

[0039] (2) Tapioca starch / polyvinyl alcohol / chitosan thin composite material preparation:

[0040] Add the above polyvinyl alcohol solution and chitosan solution into the tapioca starch solution, and add 10mL a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com