Method for simultaneous ultrasonic inversion of thickness, density and longitudinal wave velocity of coating

A technology of coating layer and density, applied in the direction of using wave/particle radiation, measuring devices, instruments, etc., can solve the problem of unseen and effective non-destructive characterization, difficult to use coating layer detection, and parts coating layer detection that cannot be applied, etc. problem, to achieve the effect of stable and reliable detection results, wide range, and convenient on-site detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

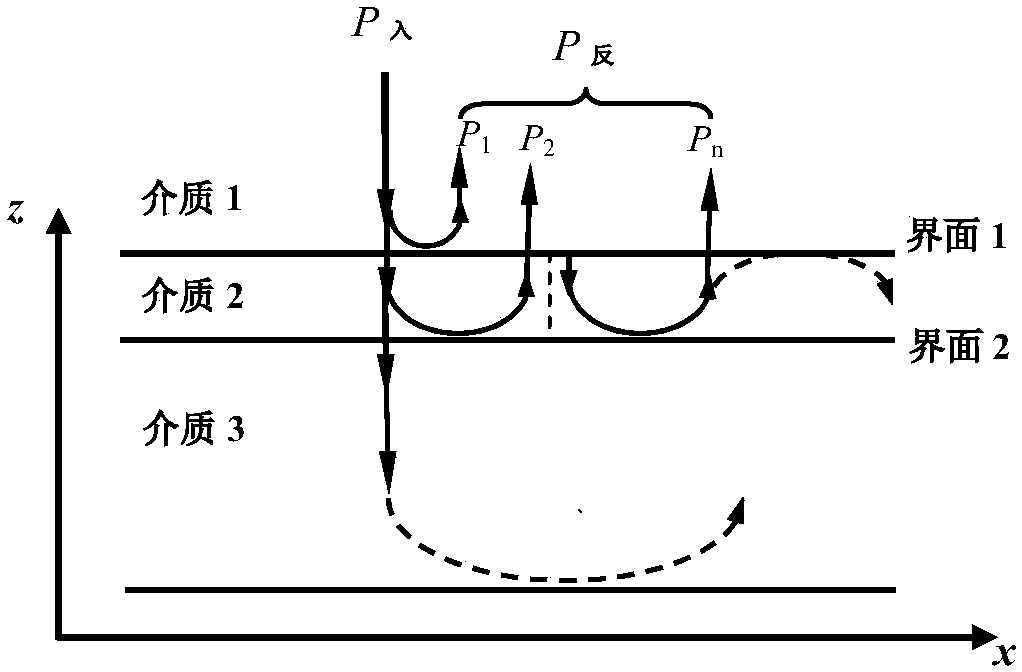

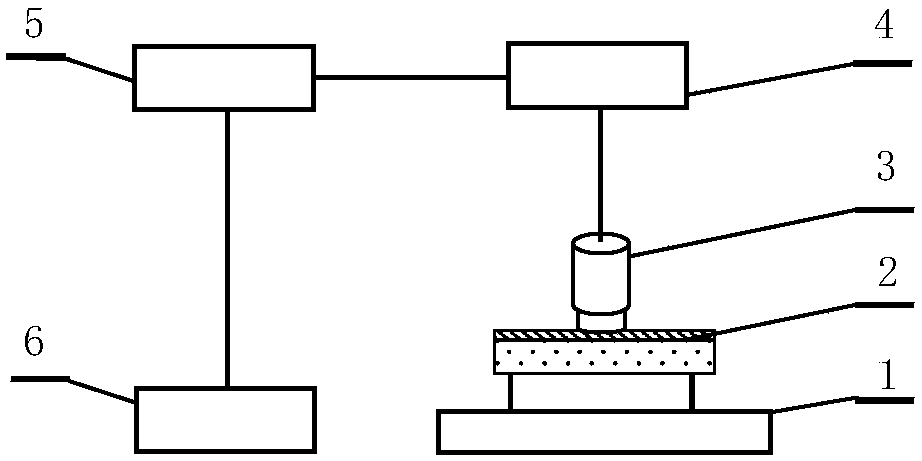

[0036] The invention relates to a method for simultaneously measuring coating layer thickness, density and longitudinal wave sound velocity by ultrasonic waves. figure 2 The one shown includes a sample table (1), a coating layer sample (the substrate is uniform aluminum alloy, the coating layer is epoxy resin containing nano-iron powder, the thickness of the coating layer is about 0.200-0.500mm, and the nominal iron Powder content of 30%, 40%, 50% of the coating layer samples to be tested) (2), center frequency 7.50MHz delay block probe, chip diameter 6.350mm (3), Olympus 5800 flaw detector (4) , DPO 4032 digital oscilloscope (5) and the ultrasonic pulse echo detection system of computer (6); the measurement steps it adopts are as follows:

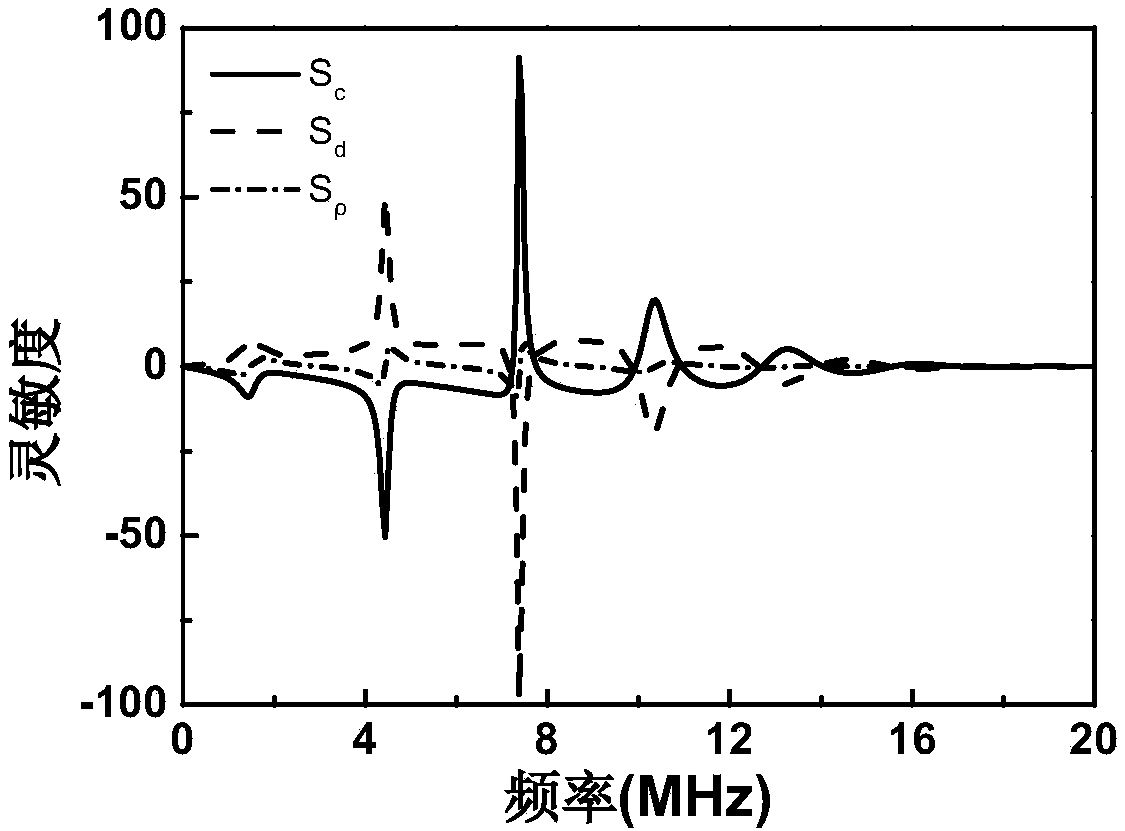

[0037] (1) According to density ρ=2214.4kg / cm 3 , thickness d = 0.347mm and longitudinal wave sound velocity c = 2053.2m / s coating sample analysis phase spectrum sensitivity to coating sample parameter inversion, see image 3 . After c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com