Strawberry harvesting integrated system based on human-machine cooperation

A human-machine collaboration, strawberry technology, applied in the direction of pickers, harvesters, agricultural machinery and implements, etc., can solve the problems of high labor intensity, difficult to automate, narrow space, etc., to reduce labor intensity, precise picking, compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

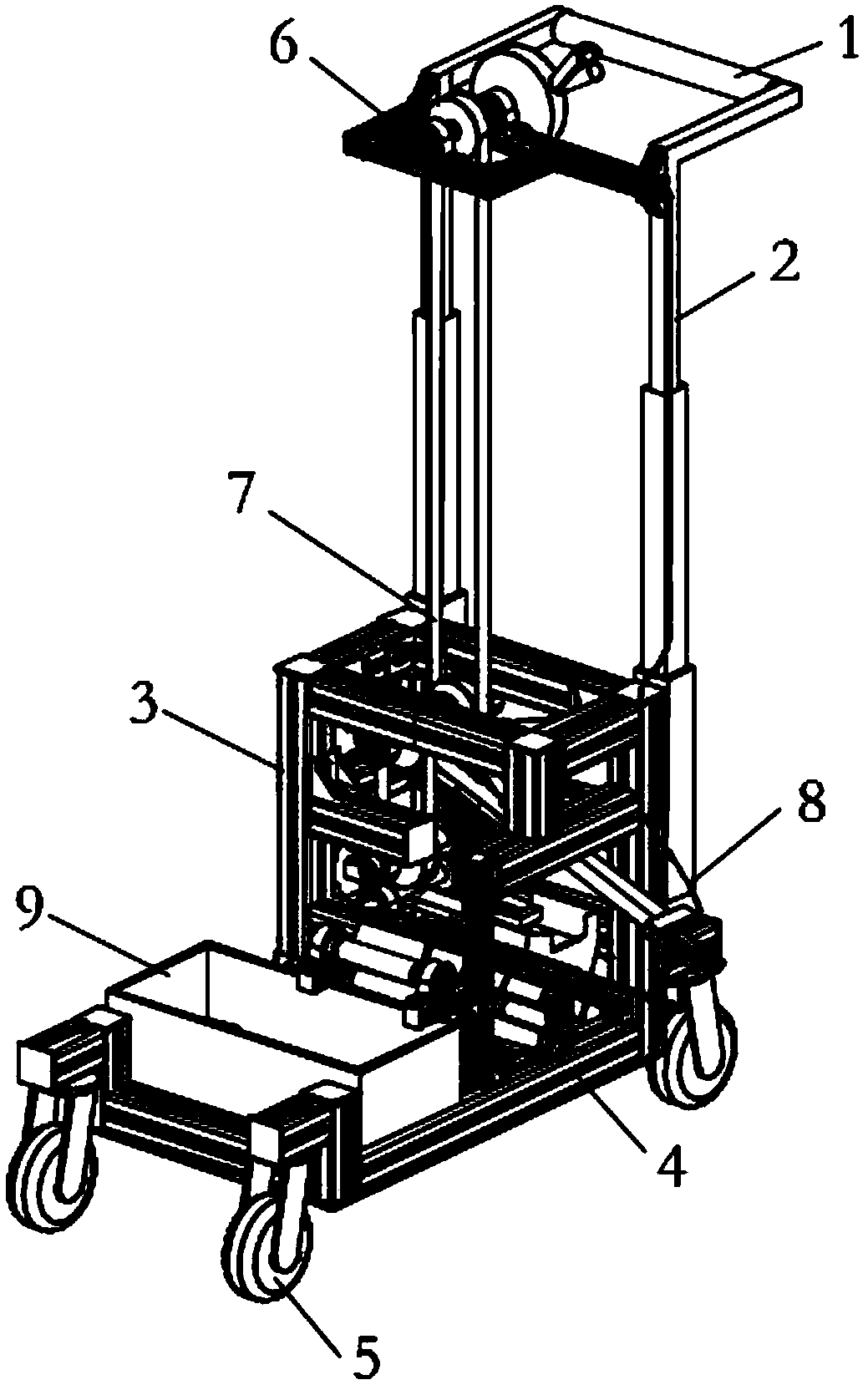

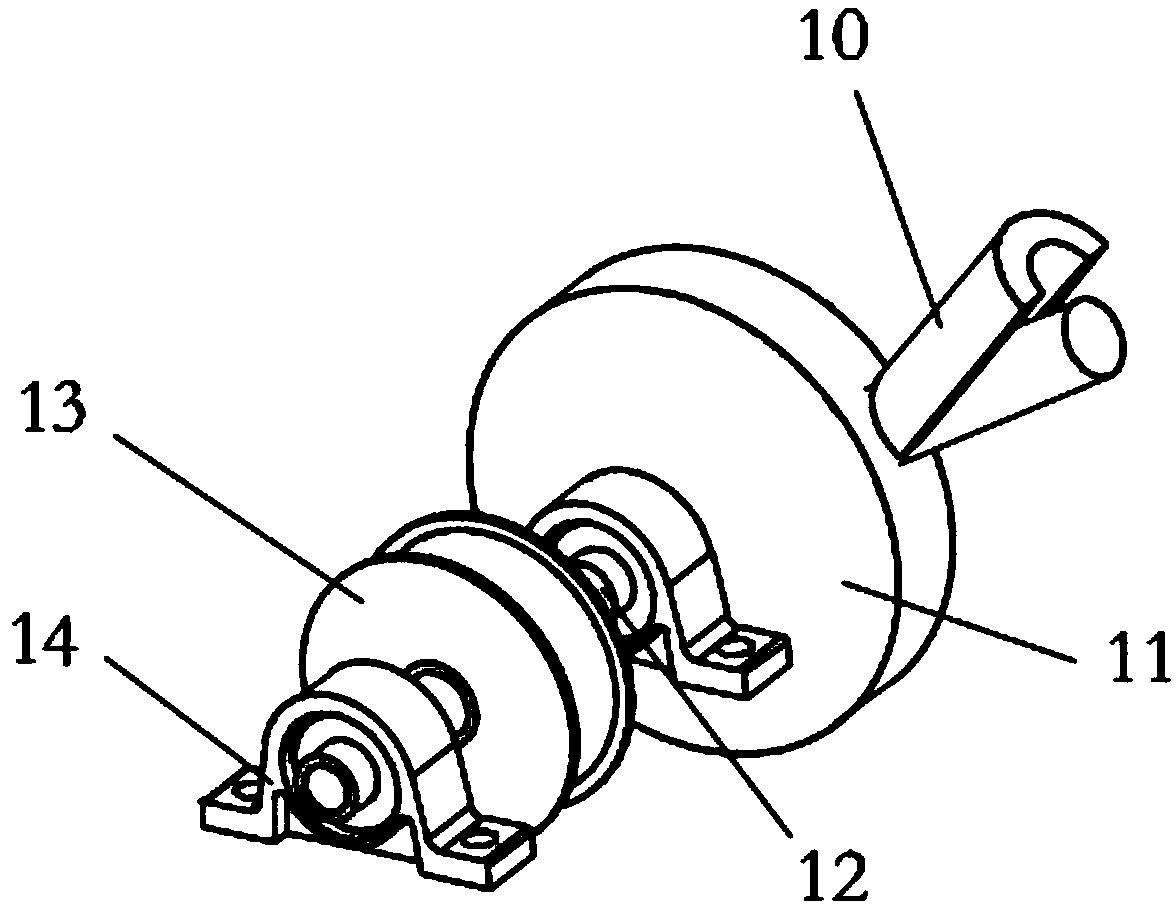

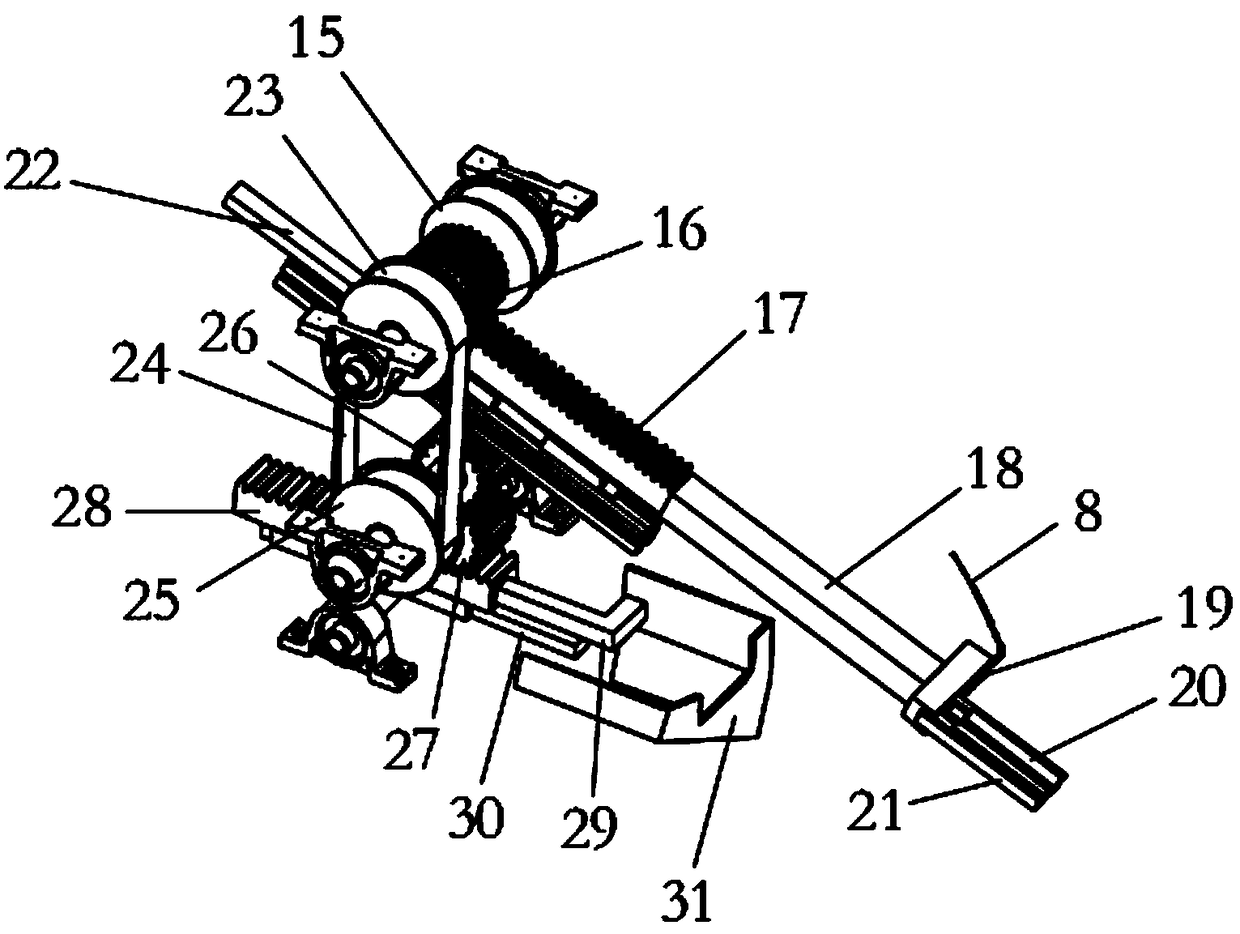

[0035] as attached Figure 1-4 As shown, the strawberry harvesting integrated system based on human-computer cooperation includes a motion bearing mechanism, a control mechanism, a picking mechanism, a primary collection mechanism and a secondary collection mechanism; figure 2 for the control body, image 3 For picking agencies and primary collection agencies, Figure 4 It is the secondary collection organization, respectively as figure 1 As shown, it is installed on the motion carrying mechanism from top to top.

[0036] The motion carrying mechanism comprises chassis 4, casters 5, carrying frame 3 and pull rod 2, and caster is arranged on the chassis bottom, and carrying frame is arranged on the chassis and is used for carrying picking mechanism, primary collecting mechanism and secondary collecting mechanism, and carrying frame is provided with The pull rod and the movement bearing mechanism make the whole system travel in the strawberry planting field in the form of a ...

Embodiment 2

[0051] When using the integrated strawberry harvesting system based on human-computer collaboration:

[0052] Picking: Turn the handwheel, through the synchronous transmission of the upper wheel of the first synchronous belt, the first synchronous belt, and the lower wheel of the first synchronous belt, the first gear and the upper wheel of the second synchronous belt rotate synchronously, and the first gear passes through the first rack Push the picking arm out, the lower wheel of the second synchronous belt rotates synchronously with the upper wheel of the second synchronous belt through the second synchronous belt, and the lower wheel of the second synchronous belt rotates the second gear in the opposite direction through the reversing gear, that is, drives the collecting arm Perform the action of shrinking back. During the process of turning the handwheel, press the button, and the spring will be tightened through the brake line, and the flexible clamp will open. When the f...

Embodiment 3

[0056] By controlling the rotation of the driving gear to make the rack move linearly, the picking actuator moves to the position of the handle above the fruit. After the flexible clamp at the end clamps the handle, the fast blade cuts off the handle, and the driving gear reverses to make the rack reverse linear motion. The picking actuator is retracted, and at the same time, the collection arm is stretched out under the action of the transmission system to the bottom of the terminal flexible clamp that clamps some fruits. At this time, the terminal flexible clamp is released, and the fruit falls to the collection transfer station. At this point, a picking is over. For the next picking, the picking actuator is stretched out, and the collection arm is retracted in the opposite direction, pushing the fruit in the collection transfer station to the conveyor belt below, and finally sending the fruit to the collection box placed on the mobile support device. At this point, a collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com