Automatic optical fiber pull-free type biliblanket weaving device

A non-pull, optical fiber technology, applied in phototherapy, radiotherapy, thin material processing, etc., can solve the problems of easy breakage of optical fiber, influence of optical energy transmission, optical fiber tearing, etc., and achieve the effect of improving optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

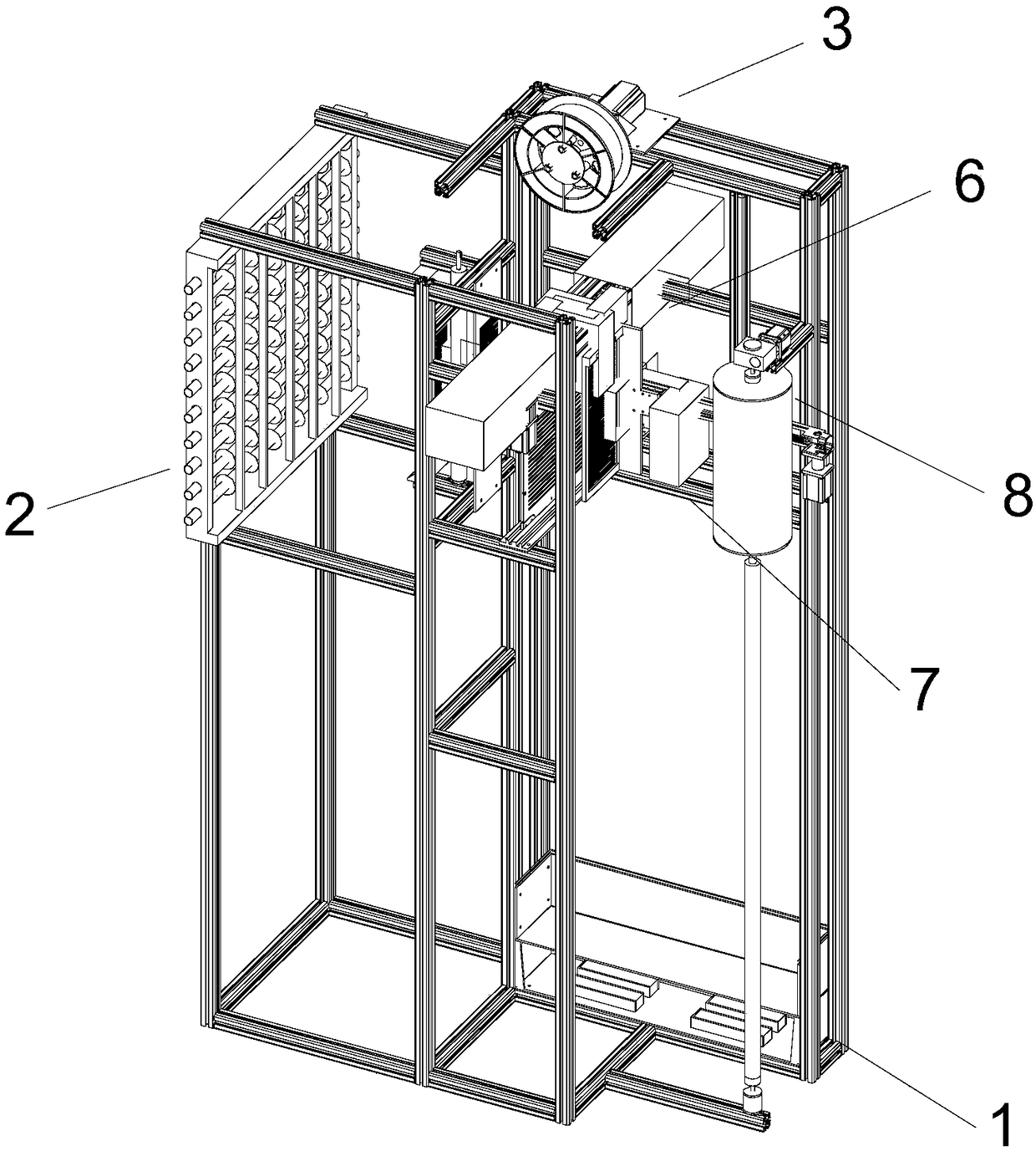

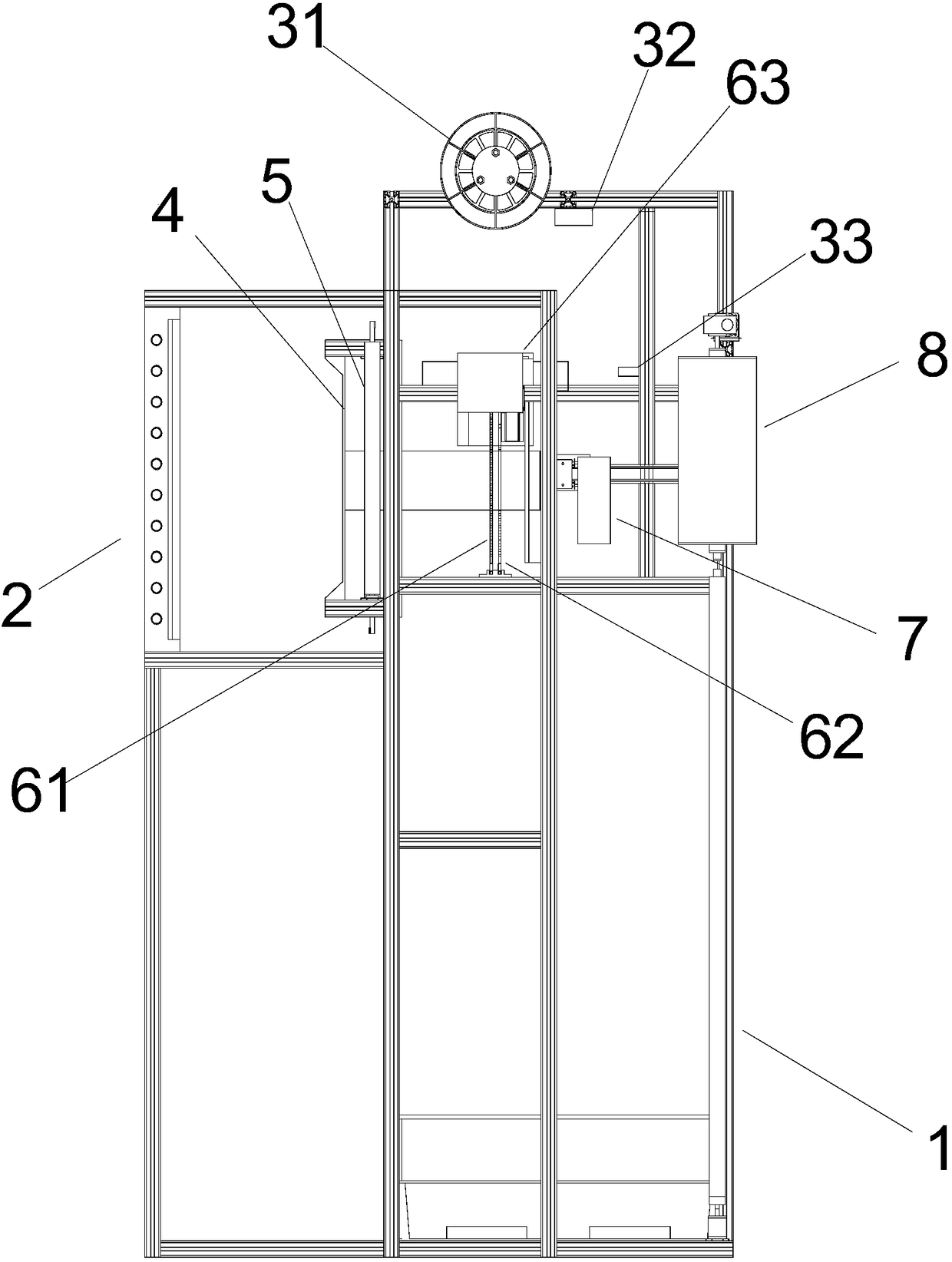

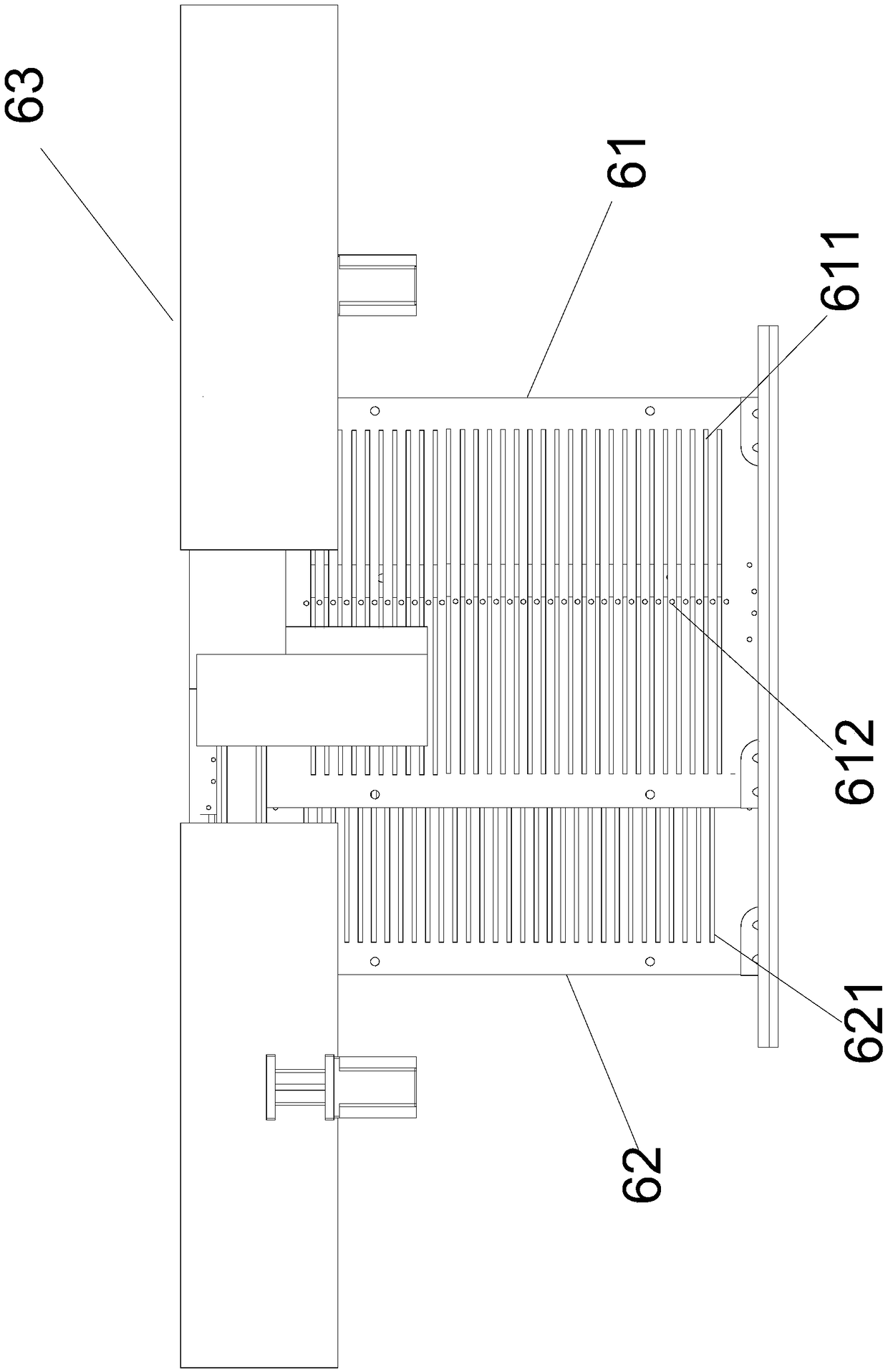

[0041] An automatic optical fiber non-pull type blue light blanket weaving equipment, such as Figures 1 to 4 As shown, a frame body 1 and an optical fiber feeding mechanism 3 without pulling effect on the optical fiber 10 are provided. The optical fiber feeding mechanism 3 is assembled on the frame body 1, and the optical fiber feeding mechanism 3 transports the optical fiber 10 to the braiding position by air blowing.

[0042] The optical fiber feeding mechanism 3 is provided with an optical fiber wheel 31 for placing the optical fiber, an air pressure device 32 for accelerating the vertical fall of the optical fiber, and a cutting device 33 for thermally severing the optical fiber. The optical fiber wheel 31, the air pressure device 32 and the cutting device 33 are respectively assembled on The frame body 1, and the air pressure device 32 is located on the top of the frame body 1.

[0043] The function of the air pressure device 32 is to blow out the compressed air in a dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com