A titanium dioxide/activated carbon composite co-doped with iron, nitrogen and cobalt, its preparation method and its application as a photocatalyst

A technology of titanium dioxide and activated carbon, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as limited application range, low degradation efficiency, and difficult control of hydrolysis speed, so as to achieve high efficiency and improve Adsorptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

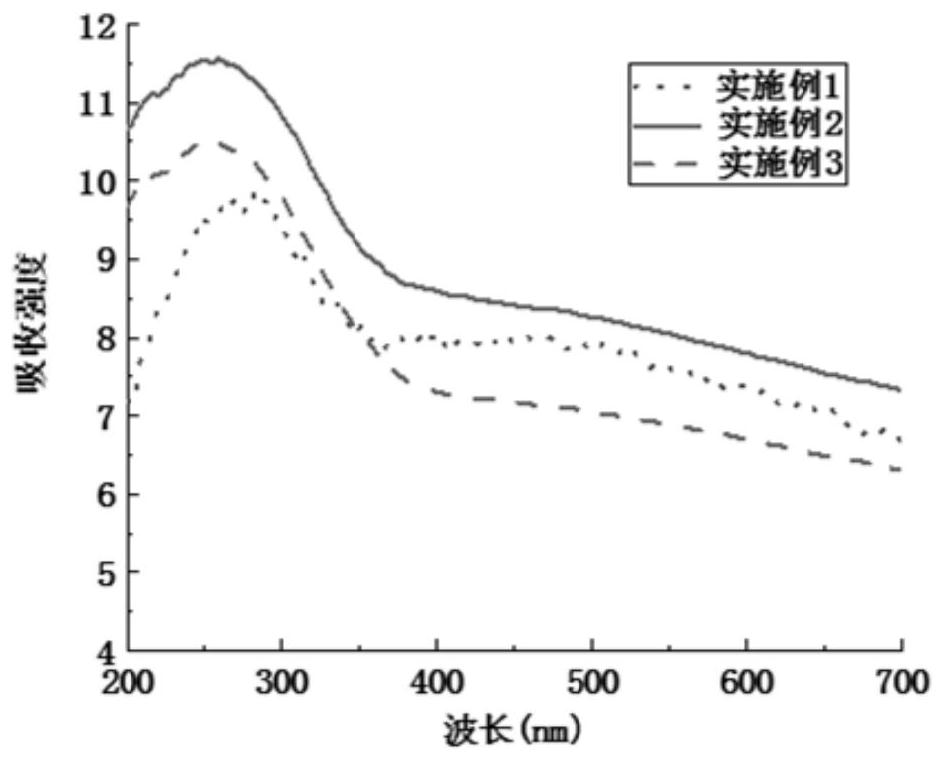

Embodiment 1

[0029] A preparation method of iron, nitrogen, cobalt co-doped titanium dioxide / activated carbon composite, the specific steps are as follows:

[0030] Step 1: Place the powdered coconut shell activated carbon in a 10% KOH solution, soak for 24 hours, then wash it with distilled water and absolute ethanol several times, and dry it for later use; lye treatment can improve the nitrogen oxides of activated carbon Selective adsorption; distilled water can remove excess KOH and other water-soluble impurities, and absolute ethanol washing can remove some residual organic impurities. Among them, the tail gas removal rate of AC (activated carbon) without KOH treatment was 39.8%, and the removal rate of AC tail gas after pretreatment was 56.1%.

[0031] Step 2: Mix absolute ethanol with a volume ratio of 5:1 and butyl titanate and stir evenly, add nitric acid to adjust the pH until the pH is 2, and obtain a mixed solution A;

[0032] Step 3: Add ferric nitrate, urea and cobalt nitrate...

Embodiment 2

[0038] A preparation method of iron, nitrogen, cobalt co-doped titanium dioxide / activated carbon composite, the specific steps are as follows:

[0039] Step 1, soak the powdered coconut shell activated carbon in a 10% NaOH solution for 24 hours, then wash it with distilled water and absolute ethanol several times, and dry it for later use;

[0040] Step 2: Mix absolute ethanol with a volume ratio of 5:1 and butyl titanate and stir evenly, and adjust the pH with nitric acid until the pH is 1 to obtain a mixed solution A;

[0041]Step 3: Add the three dopants of ferric nitrate, urea and cobalt nitrate to the mixed solution A, stir at high speed until they are all dissolved, and obtain the mixed solution B, wherein the mass ratio of ferric nitrate, urea, cobalt nitrate and butyl titanate is 0.05:0.08:0.07:1;

[0042] Step 4: Put the activated carbon carrier prepared in step 1 in a petri dish, absorb the mixed solution B and add it dropwise to the activated carbon, disperse it by...

Embodiment 3

[0047] A preparation method of iron, nitrogen, cobalt co-doped titanium dioxide / activated carbon composite, the specific steps are as follows:

[0048] Step 1, after immersing the powdered coconut shell activated carbon in a KOH solution with a concentration of 10% for 24 hours, wash it with distilled water and absolute ethanol several times, and dry it for later use;

[0049] Step 2: Mix and stir absolute ethanol and butyl titanate with a volume ratio of 5:1, and adjust the pH with sulfuric acid until the pH is 1.5 to obtain a mixture A;

[0050] Step 3: Add the three dopants of ferric nitrate, urea and cobalt nitrate to the mixed solution A, stir at high speed until they are all dissolved, and obtain the mixed solution B, wherein the mass ratio of ferric nitrate, urea, cobalt nitrate and butyl titanate is 0.05:0.08:0.07:1;

[0051] Step 4: Place the activated carbon carrier prepared in step 1 in a petri dish, absorb the mixed solution B and add it dropwise to the activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com