Heat-sealing films and wrapping tapes for packaging electronic components

A technology of heat-sealing film and covering tape, which is applied to the structural parts of electrical equipment, packaging, and electrical components. The effect of good optical properties and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0068] Preparation of materials for functional layers :

[0069] 67.5 kg of styrene-butadiene block copolymer (CHI MEI, PB-5903), 37.5 kg of poly(vinyl acetate) (HyunDai, VA60), 45 kg of intrinsically antistatic polymer ( IDP: PolyNova PNC300R-M) and 0.6kg of Antioxidant A5 (Jinhai Albemarle, Shanghai Jinhai Albemarle Fine Chemicals Co, Ltd.) were stirred evenly and heated at 180°C melt mixing, followed by cooling and granulation for further applications.

[0070] Preparation of Heat Seal Film and Cover Tape :

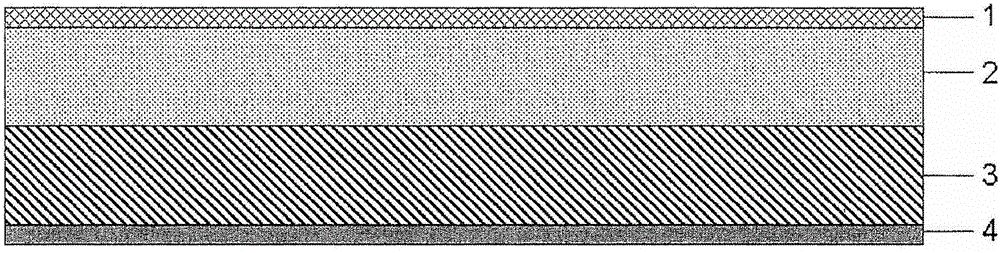

[0071] 1. A 16 μm thick biaxially stretched polyester film treated with corona discharge on one side was prepared. The corona-discharge-treated surface was coated with a polyurethane-based primer about 0.2 μm thick, followed by baking in an oven. Simultaneously, the polymer alloy prepared for the functional layer was melt-coated onto the primer-coated polyester film, and the obtained product was subsequently cooled and wound. The functional layer has a thicknes...

example 2

[0076] Preparation of materials for functional layers :

[0077] 67.5kg of styrene-butadiene block copolymer (CHI MEI, PB-5903), 37.5kg of polyvinyl acetate (Hyundai, VA60), 45kg of inherent antistatic polymer (IDP: PolyNova PNC300R-M) and 0.6kg of Antioxidant A5 (Jinhai Yabao, Shanghai Jinhai Yabao Fine Chemical Co., Ltd.) were uniformly stirred, and melt mixed at 180 ° C, followed by cooling and granulation for further application .

[0078] Preparation of Heat Seal Film and Cover Tape :

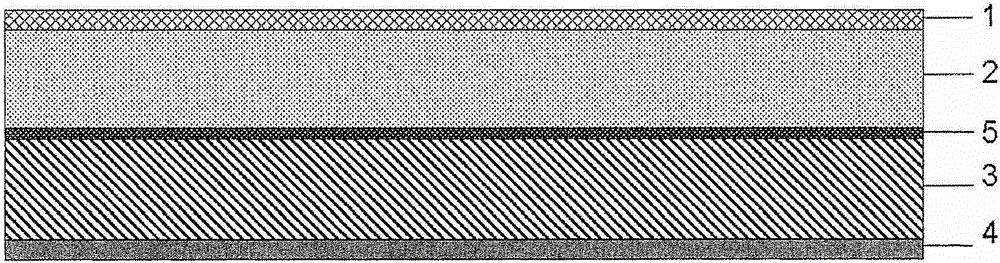

[0079] 1. A 16 μm thick biaxially stretched polyester film treated with corona discharge on one side was prepared. The corona-discharge-treated surface was coated with a polyurethane-based primer about 0.2 μm thick, followed by baking in an oven. Simultaneously, the polymer alloy prepared for the functional layer was melt-coated onto the primer-coated polyester film, and the obtained product was subsequently cooled and wound. The functional layer has a thickness of 30 μm and a 1×10...

example 3

[0084] Preparation of materials for functional layers :

[0085] 80kg of styrene-butadiene block copolymer (CHI MEI, PB-5903), 20kg of poly(vinyl acetate) (Hyundai, VA60) and 0.4kg of antioxidant A5 (Jinhai Yabao , Shanghai Jinhai Yabao Fine Chemical Co., Ltd.) were uniformly stirred and melt-mixed at 180° C., followed by cooling and granulation for further applications.

[0086] Preparation of Heat Seal Film and Cover Tape :

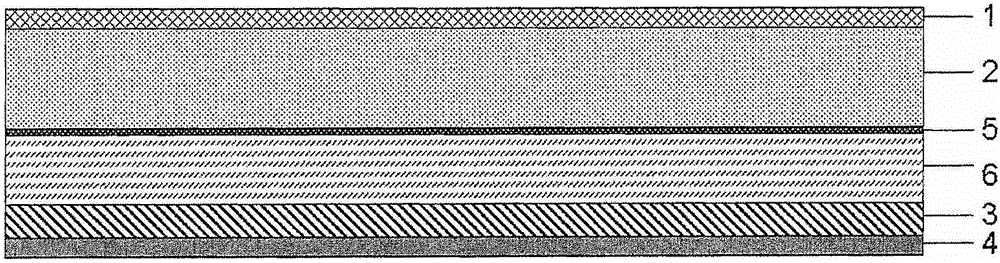

[0087] 1. The material prepared for the functional layer is formed into a film by blow molding and wound up for further application. The thickness of the film was 35 μm.

[0088] 2. A 12 μm thick biaxially stretched polyester film treated with corona discharge on one side was prepared. The corona treated surface was coated with polyurethane glue (35%, adhesive from MITSUI TAKEDA CHEMICAL JNC, 3 / 1 for A-969V / A-5). After baking, the thickness of the glue is about 2 μm. The prepared functional layer film was combined with the surface of the polyes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com