Efficient solid-liquid reverse flow extraction device and extraction method

A leaching and countercurrent technology, applied in the field of high-efficiency solid-liquid countercurrent leaching devices, to achieve the effect of increasing the floor area, realizing automatic operation, and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

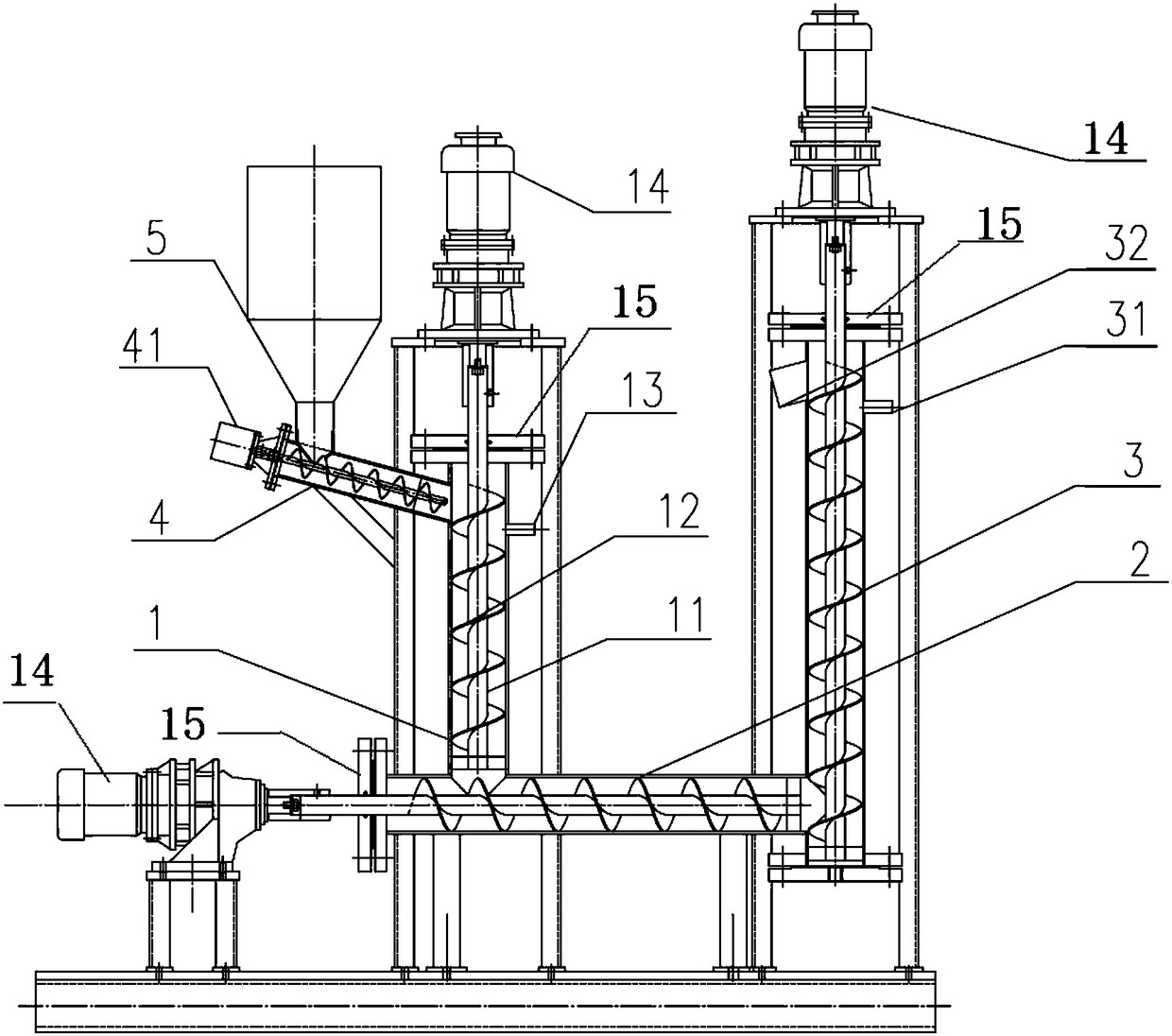

[0042] Embodiment 1 extracts glycyrrhizic acid from licorice

[0043] Glycyrrhiza licorice is crushed into filaments, and 75% ethanol aqueous solution is used as a solvent. Carry out leaching in the UJ-80 type extractor, the rotating speed is 8rpm;

[0044] (1), put the crushed licorice filaments into the feed bin, and adjust the rotating speed of the solid material propeller to be 8rpm;

[0045] (2), the aqueous ethanol solution of solvent-75% is put into the solvent storage tank, and is connected with the solvent inlet of the third group stirring device 3, and the flow rate of setting solvent is 25L / h;

[0046] (3), the extraction solution outlet of the first group of stirring devices 1 is connected with the extraction solution storage tank;

[0047] (4), the stirring speed that the first group of stirring device 1, the second group of stirring device 2, the third group of stirring device 3 are set by frequency converter is 8rpm;

[0048] (5), start the motor of the stirr...

Embodiment 2

[0054] Example 2 Extraction of Coenzyme Q10 Cell Broken Body

[0055] In the production process of coenzyme Q10, the leaching of fermented cell crushed powder.

[0056] (1), put the fermented cell crushed powder into the feed bin, and adjust the rotating speed of the solid material propeller to 5rpm;

[0057] (2), solvent normal hexane is put into solvent storage tank, and is connected with the solvent inlet of the third group stirring device 3, and the flow rate of setting solvent is 20L / h;

[0058] (3), the extraction solution outlet of the first group of stirring devices 1 is connected with the extraction solution storage tank;

[0059] (4), the stirring speed that the first group of stirring device 1, the second group of stirring device 2, the third group of stirring device 3 are set by frequency converter is 6rpm;

[0060] (5), start the motor of the spiral stirring device;

[0061] (6), open the solvent delivery pump, and make the solvent enter the spiral stirring dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com