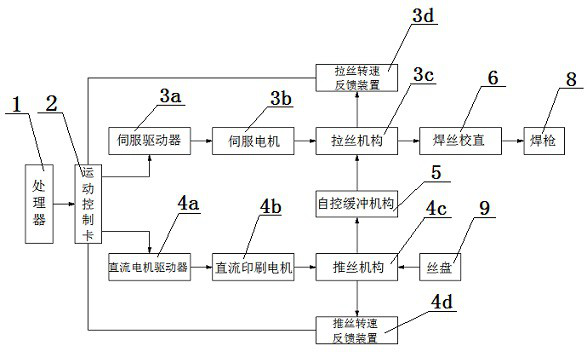

A programmable pulse wire feeding control system

A control system and wire feeding technology, which is applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems that are not suitable for scientific research needs, few controllable parameters, and low wire feeding accuracy, so as to achieve more flexible controllable parameters Variable, easy and reliable operation, high wire feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] At the average wire feeding speed V = 100mm / s, T 1 = T 2 =50ms, pause time T 3 =0, for example, if it is desired that the wire retraction distance per cycle is 2mm, that is, V 2 *T 2 =2mm, it can be known by calculation that V 2 =40mm / s, V 1 =240mm / s.

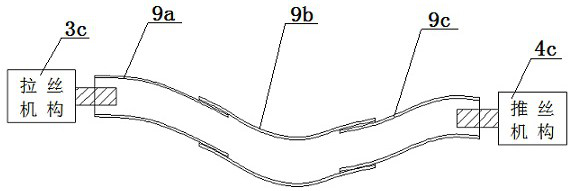

[0033] The operator first transmits the characteristic parameters of the pulse wire feeding process to the processor. The characteristic parameters are: average wire feeding speed V=100mm / s, T 1 = T 2 =50ms, pause time T 3 =0,V 1 =240mm / s. V 2 =40mm / s, the processor sets the speed of the BLS AC servo motor and 120SN10-CQ printing DC motor through the motion control card ADT-8948 according to the above parameters; Take out the contact tip of the welding torch.

[0034] When the normal wire feeding process starts, according to the characteristic parameter value of the pulse wire feeding process, the wire pushing mechanism is driven by the 120SN10-CQ DC printing motor to independently rotate a certain distance ...

Embodiment 2

[0038] With the average wire feeding speed V=100mm / s, the changed wire feeding speed V 4 =200mm / s, the duration T of the changed state 4 =10ms as an example, if the control requirement is: when the arc voltage is detected to be higher than a certain value, it is determined that the wire feeding speed needs to be increased in real time during the constant speed wire feeding process, and the speed returns to the average speed after a period of time.

[0039] The operator first sends the characteristic parameters of the pulse wire feeding process to the computer through the computer. The characteristic parameters are: average wire feeding speed V=100mm / s, V 4 =200mm / s, the duration T of the changed state 4 =10ms, the computer sets the speed of the BLS AC servo motor and 120SN10-CQ printing DC motor through the motion control card ADT-8948 according to the above parameters; then install the wire reel to the wire pushing mechanism, and manually feed the wire so that the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com