Novel wire harness contact injection molding strip transfer mechanism

A wire harness and mold strip technology, which is applied in the field of new wiring harness contact injection molding mold strip operation mechanism, can solve the problems of increased space occupied by production equipment, high requirements for workshop space, and huge equipment, and achieve a reasonable layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

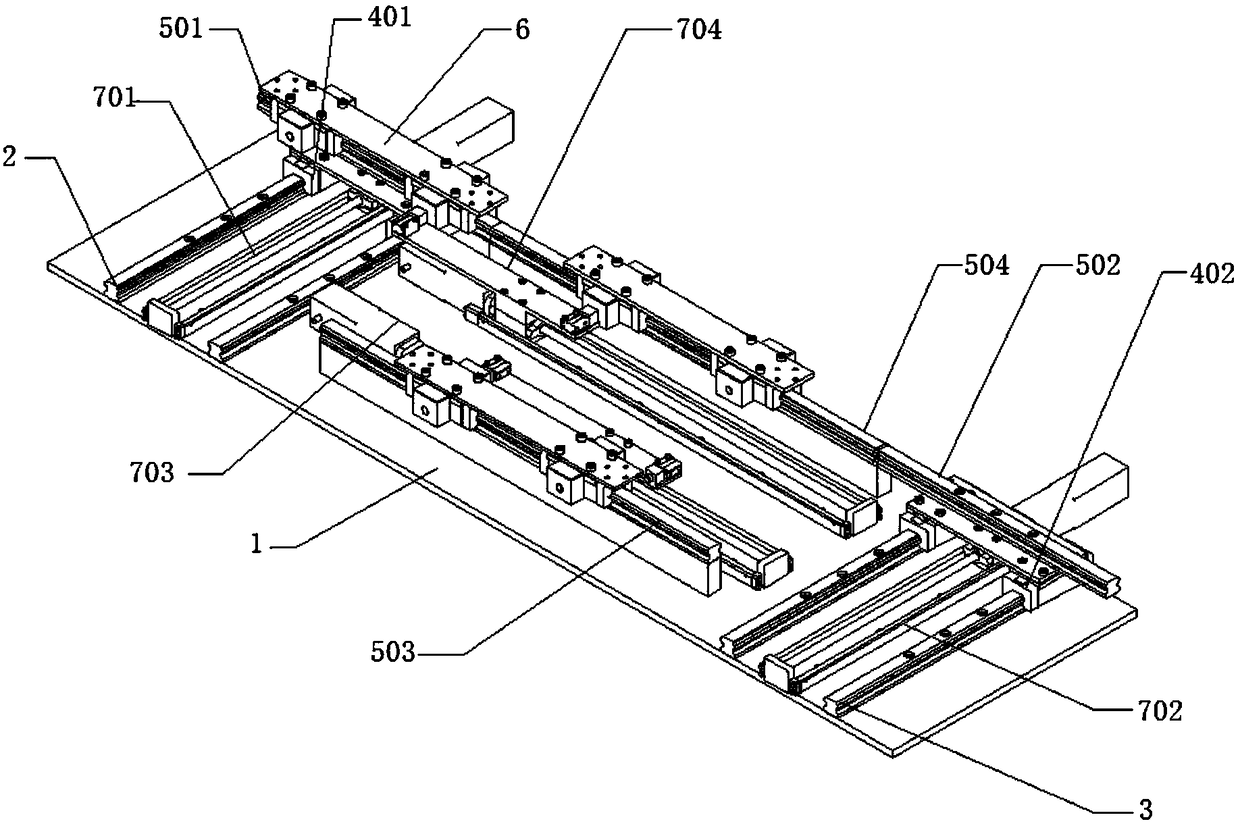

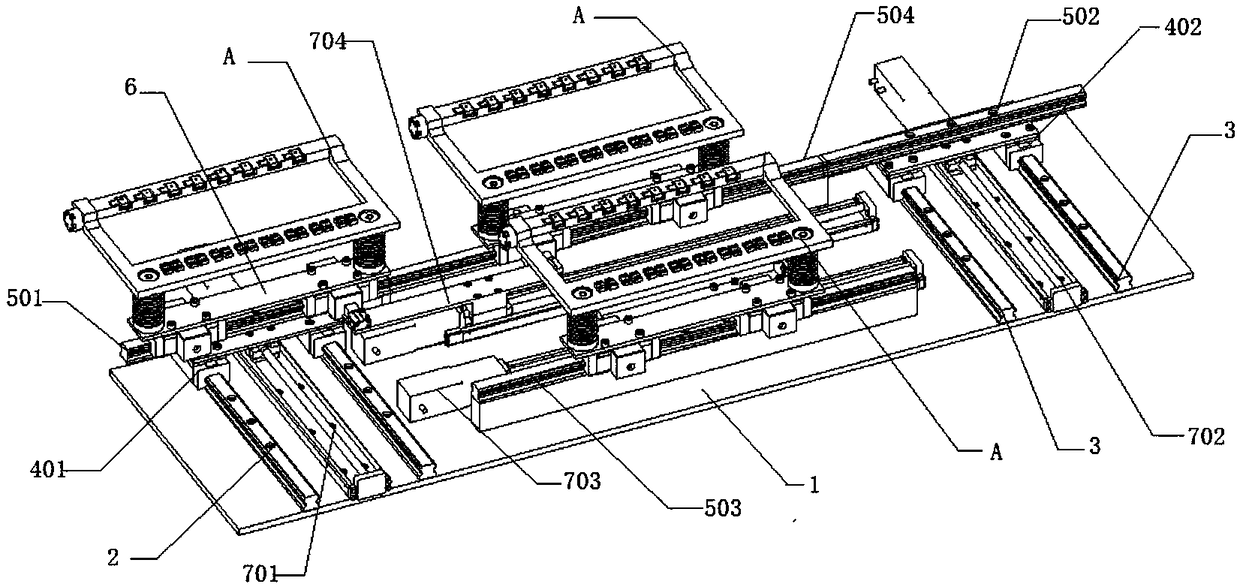

[0033] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , a new type of wire harness contact injection molding operating mechanism provided by the embodiment of the present invention, such as figure 1 , figure 2 As shown, the mechanism includes a rectangular bottom plate 1, and the rectangular bottom plate 1 is used to carry various components;

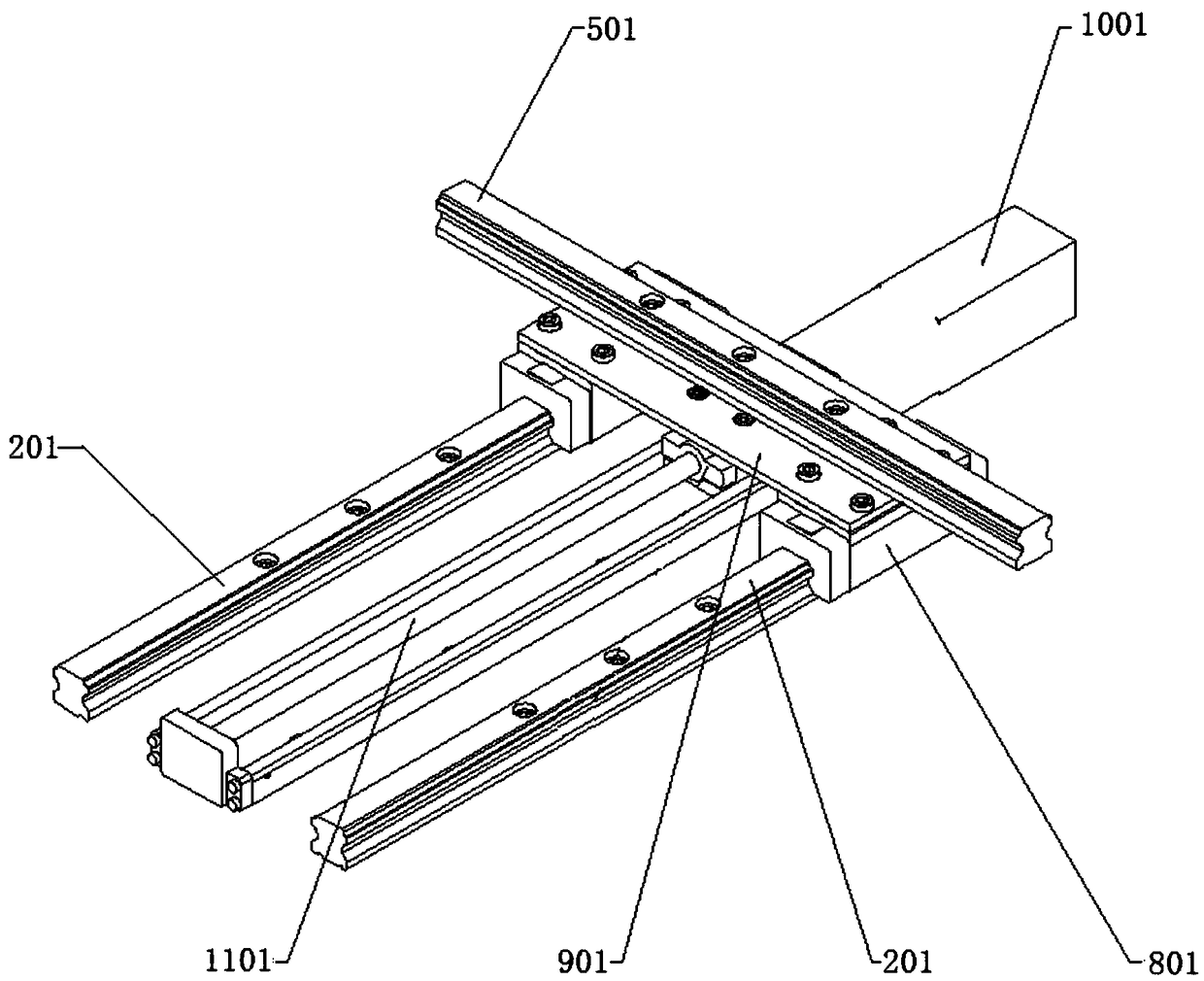

[0034] The first longitudinal sliding rail group 2 and the second longitudinal sliding rail group 3 are vertically arranged, the first longitudinal sliding rail group 2 includes two first longitudinal sliding rails 201 vertically arranged on the rectangular bottom plate 1, two The first longitudinal slide rails 201 are respectively connected to the first longitudinal slide assemblies 401, the upper part of the first longitudinal slide assemblies 401 is fixedly connected with the first transverse slide rails 501, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com