Preparation method of plate-shaped ceramic tile bonding agent

A tile adhesive and plate-shaped technology, which is applied in the field of preparation of plate-shaped tile adhesives, can solve the problems of inconvenient use of tile adhesives, achieve simple and quick laying process, save stirring steps, and promote water effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a plate-shaped ceramic tile adhesive, comprising the steps of material preparation, mixing, pressing and drying, specifically as follows.

[0036] Material preparation: plastic solid waste is ball-milled and granulated with water to make plastic granules, and the moisture content of the plastic granules is 7-10%. The plastic particles with this moisture content are mixed with the binder and then pressed, which has a good molding effect and can ensure the stability of the binder, which is convenient for the storage of the adhesive for plate-shaped tiles and does not affect the adhesive effect of the binder.

[0037] Mixing: mix the plastic granules and the binder uniformly to obtain the mixture, and the weight ratio of the plastic granules to the binder is (0.5-1):2. The binder is powder, which can be fully mixed with plastic particles.

[0038] The plastic solid waste enables the plate-shaped tile adhesive to maintain a certain shape and have suf...

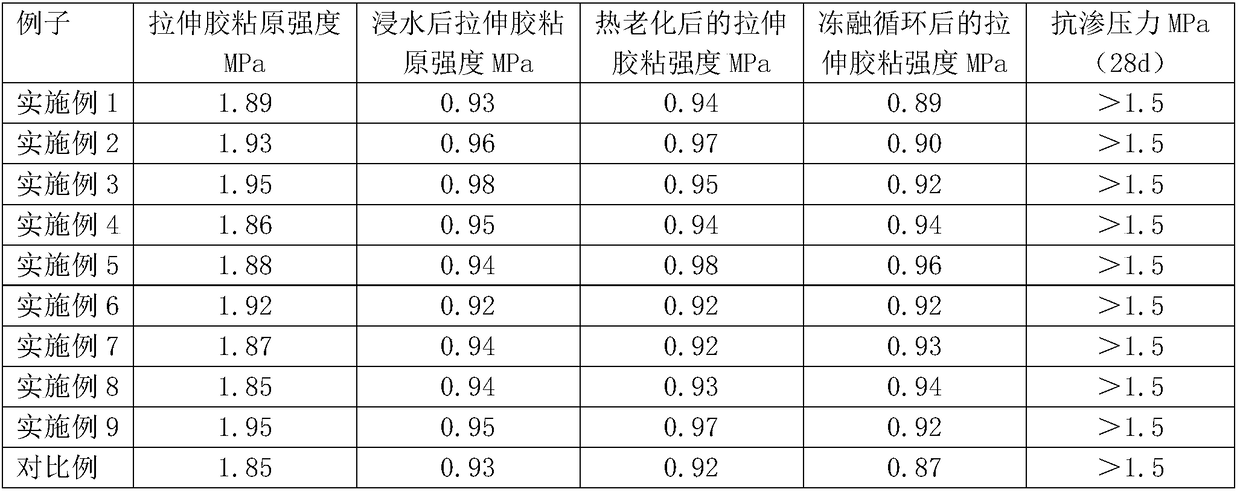

Embodiment 1

[0058] A preparation method of a plate-shaped ceramic tile adhesive, comprising the following steps:

[0059] Material preparation: ball mill the plastic solid waste, add water and granulate to make plastic granules, and the moisture content of the plastic granules is 7%;

[0060] Mixing: Mix the plastic granules and the binder evenly to obtain the mixture. The weight ratio of the plastic granules to the binder is 1:2; the plastic granules and the binder are mixed with a dry powder mortar mixer for 30 minutes. The particle size of the plastic particles is 120 mesh.

[0061] Pressing: pressing the mixture into a plate-shaped green body; the pressing pressure is 30MPa.

[0062] Drying: The green body is dried to obtain a tile adhesive in the form of a plate.

[0063] The obtained tile adhesive has a compressive strength ≥ 1.2 MPa. The tile adhesive obtained had a thickness of 1 mm.

[0064] The plastic solid waste includes one or more of kaolin tailings, calcined shale and c...

Embodiment 2

[0068] A preparation method of a plate-shaped ceramic tile adhesive, comprising the following steps:

[0069] Material preparation: ball mill the plastic solid waste, add water and granulate to make plastic granules, the moisture content of the plastic granules is 8%;

[0070] Mixing: Mix the plastic granules and the binder evenly to obtain the mixture. The weight ratio of the plastic granules to the binder is 0.76:2; the plastic granules and the binder are mixed with a dry powder mortar mixer for 40 minutes. The particle size of the plastic particles is 100 mesh.

[0071] Pressing: pressing the mixture into a plate-shaped green body; the pressing pressure is 25MPa.

[0072] Drying: The green body is dried to obtain a tile adhesive in the form of a plate.

[0073] The obtained tile adhesive has a compressive strength ≥ 1.2 MPa. The thickness of the tile adhesive obtained was 2 mm.

[0074] The plastic solid waste includes one or more of kaolin tailings, calcined shale and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com