Method for reinforcing box girder by pre-stress shear-resistance

A prestressed and box girder technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of not considering the tension space, increasing the weight of the box girder, and low tension efficiency, etc., and achieve high engineering application value , saving construction period, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

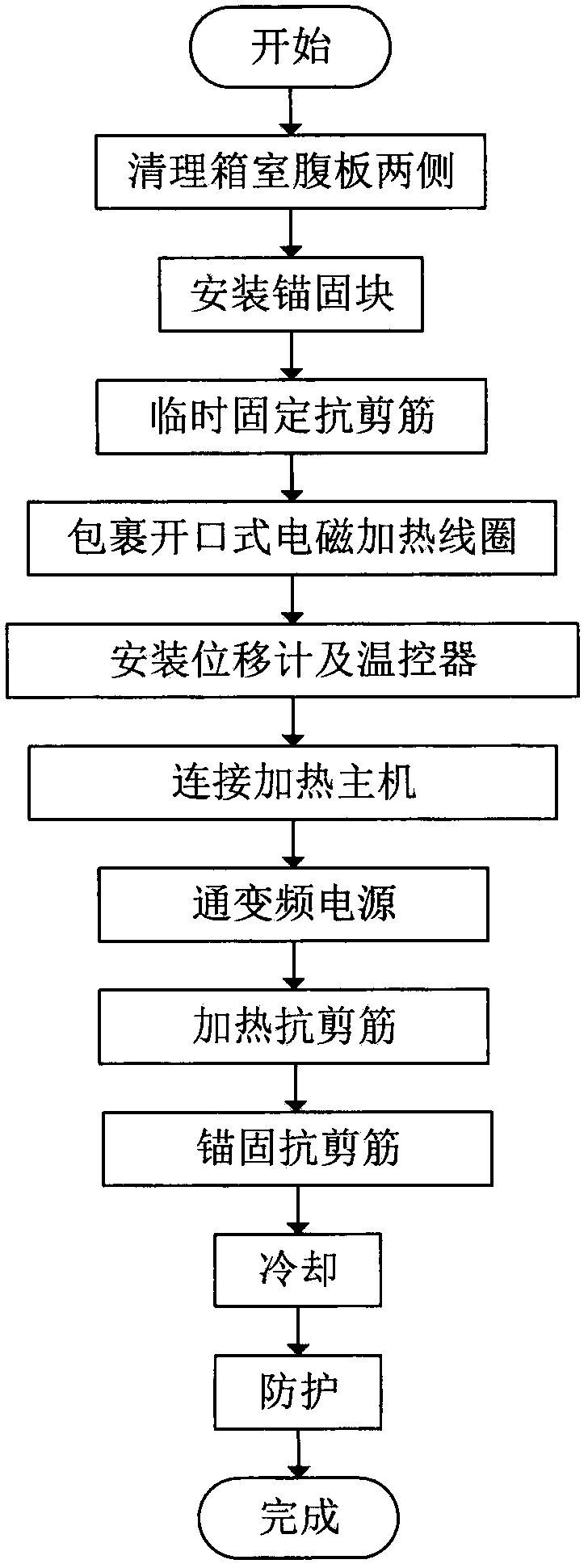

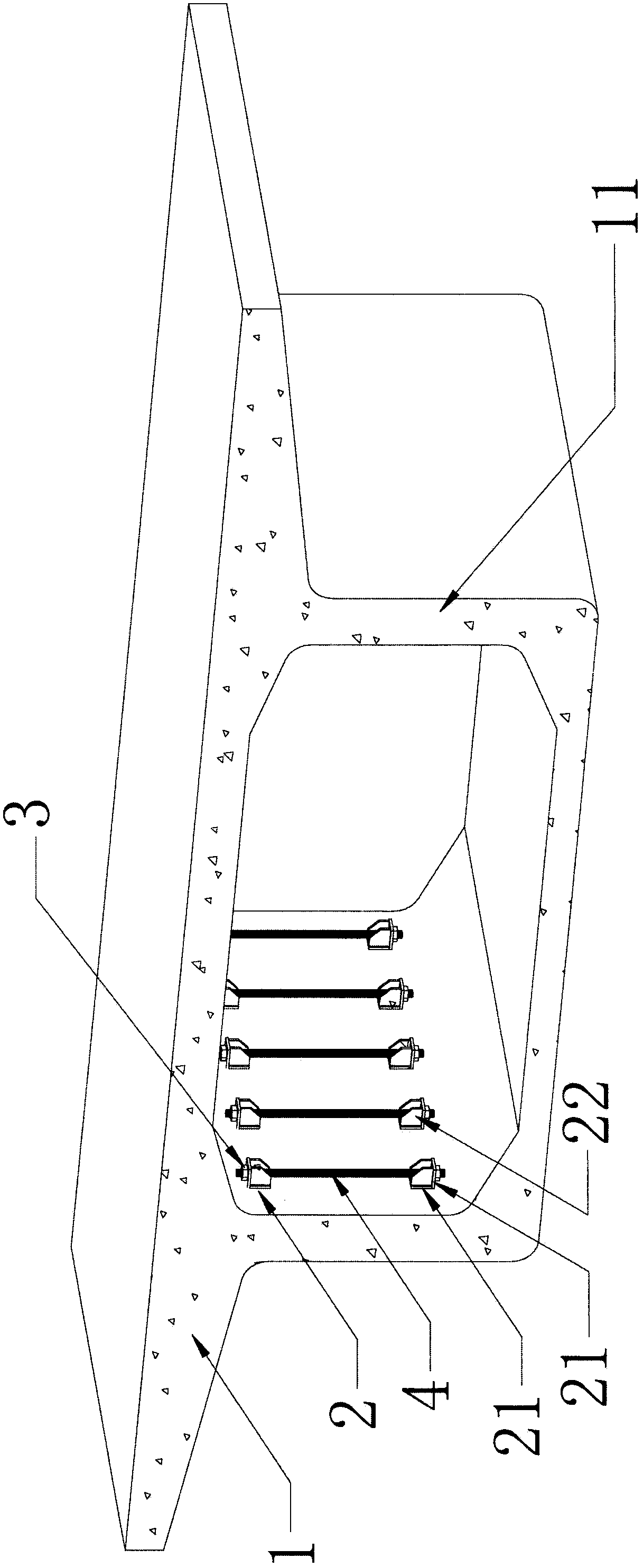

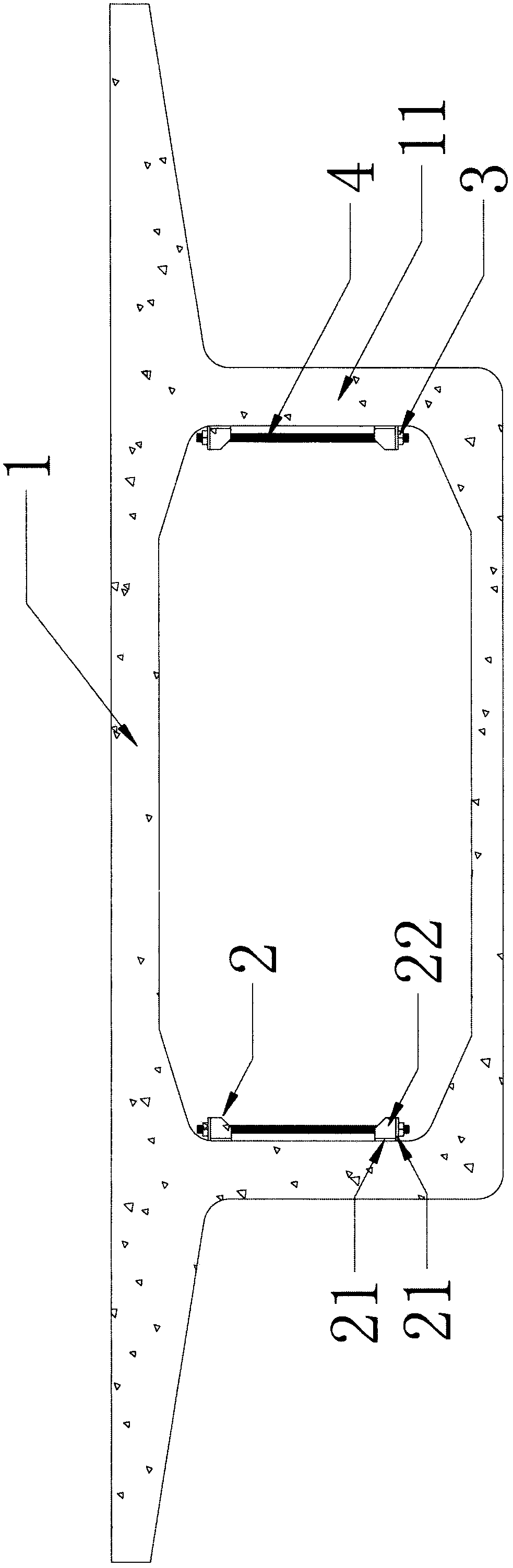

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The present invention provides a method for prestressed and shear-resisting reinforced box girders. By installing anchor blocks 2 on both sides of the web 11 of the box chamber of the box girder 1, the anchor blocks 2 are temporarily fixed between the two anchor blocks 2. The shear reinforcement 4 is wrapped around the shear reinforcement 4 with a prefabricated open-type electromagnetic heating coil 5 and connected to the heating host 8. The high-frequency magnetic field generated by the frequency conversion power supply 9 is used to make the shear reinforcement 4 heat rapidly by itself, and the temperature controller 6 Control the electromagnetic heating temperature, the displacement meter 7 controls the elongation of the shear rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com