Nitride semiconductor light emitting device and manufacturing method thereof

A technology of nitride semiconductors and light-emitting devices, which is applied to the structure of semiconductor devices, semiconductor lasers, and optical waveguide semiconductors. It can solve problems such as easy contamination, affecting device performance and life, and large device resistance. Achieve stability and Good reliability, improved performance and life, and low threshold current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] Embodiment 1 The manufacturing process of a GaN-based blue laser or superluminescent light-emitting diode in this embodiment includes:

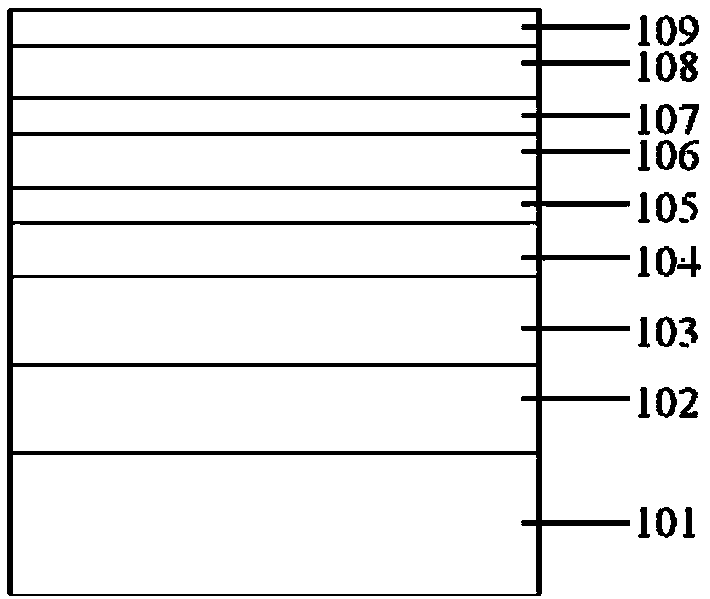

[0133] S1: Using metal organic chemical vapor deposition (MOCVD) equipment to grow nitride semiconductor laser or superluminescent light emitting diode structure on GaN substrate, which includes: n-GaN contact layer with a thickness of about 500nm; 100 pairs of n-Al 0.16 GaN / GaN superlattice structure, in which each layer is about 2.5nm thick as n-type optical confinement layer; n-In with a thickness of about 100nm 0.03 Ga 0.97 N waveguide layer; 3 pairs of In 0.16 Ga 0.84 N / GaN multiple quantum wells, where each layer of In 0.16 Ga 0.84 The N quantum well is about 2.5nm thick, and each GaN barrier is about 15nm thick; the unintentionally doped In with a thickness of about 80nm 0.03 Ga 0.97 N waveguide layer; p-Al with a thickness of about 20nm 0.2 Ga 0.8 N electron blocking layer; 150 pairs of p-Al 0.16 a GaN / GaN superlattice...

Embodiment 2

[0144] Embodiment 2 The manufacturing process of a GaN-based near-ultraviolet laser in this embodiment includes:

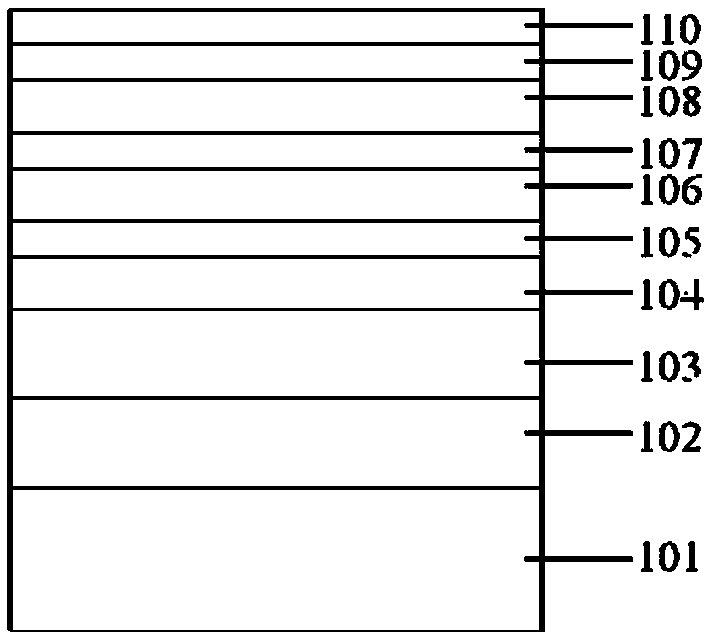

[0145] S1: Using metal organic chemical vapor deposition (MOCVD) equipment to grow ultraviolet laser structures on Si(111) substrates, including: n-GaN contact layer with a thickness of about 500nm; 120 pairs of n-Al 0.2 GaN / GaN superlattice structure, in which each layer is about 2.5nm thick as an n-type optical confinement layer; n-Al with a thickness of about 80nm 0.02 Ga 0.98 Nn side waveguide layer; 2 pairs of In 0.03 Ga 0.97 N / Al 0.08 Ga 0.92 N multiple quantum wells, where each layer of In 0.03 Ga 0.97 The N quantum well is about 2.5nm thick, each layer of Al 0.08 Ga 0.92 N barrier about 14nm thick; unintentionally doped Al about 60nm thick 0.02 Ga 0.98 Np side waveguide layer; p-Al about 25nm thick 0.25 Ga 0.75 N electron blocking layer; 30 pairs of p-Al 0.16 GaN / GaN superlattice structure, wherein each layer has a thickness of about 2.5nm as ...

Embodiment 3

[0158] Embodiment 3 The manufacturing process of an AlGaN-based deep ultraviolet laser in this embodiment includes:

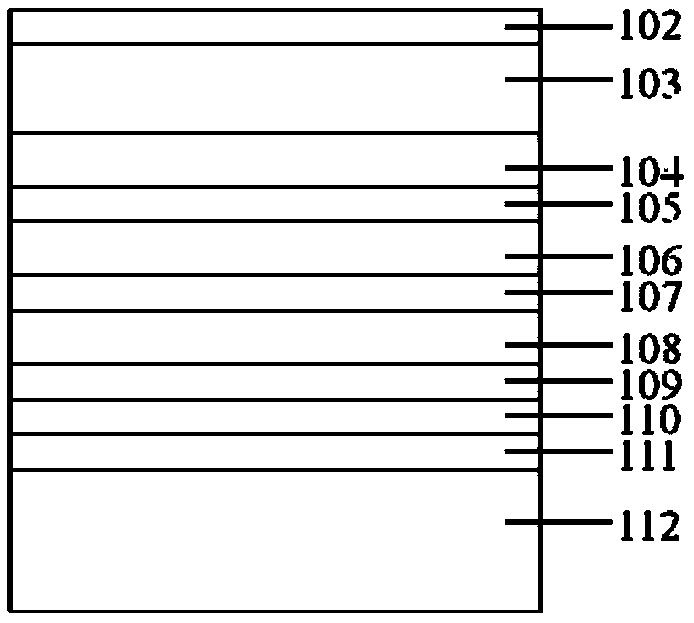

[0159] S1: Using metal organic chemical vapor deposition (MOCVD) equipment to grow deep ultraviolet laser structures on sapphire substrates, including: n-Al with a thickness of about 1000nm 0.45 Ga 0.5 N contact layer; 100 pairs of n-Al 0.65 Ga 0.35 N / Al 0.45 Ga 0.55 N superlattice structure, in which each layer is about 2.3nm thick as an n-type optical confinement layer; n-Al with a thickness of about 75nm 0.45 Ga 0.55 Nn side waveguide layer; 3 pairs of Al 0.35 Ga 0.65 N / Al 0.45Ga 0.55 N multiple quantum wells, where each layer of Al 0.35 Ga 0.65 The N quantum well is about 3nm thick, and each layer of Al 0.45 Ga 0.55 N barrier about 10nm thick; unintentionally doped Al about 60nm thick 0.45 Ga 0.55 Np side waveguide layer; p-Al about 20nm thick 0.65 Ga 0.35 N electron blocking layer; p-Al about 50nm thick 0.45 Ga 0.55 N-contact layer. ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com