Processing system and method for paper mulberry, caragana korshinskii, protein-enriched mulberry and straw feed

A technology of straw feed and processing system, which is applied in the direction of feed, cutting equipment, agricultural machinery and implements, can solve problems such as inability to realize processing, and achieve the effect of improving the puffing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

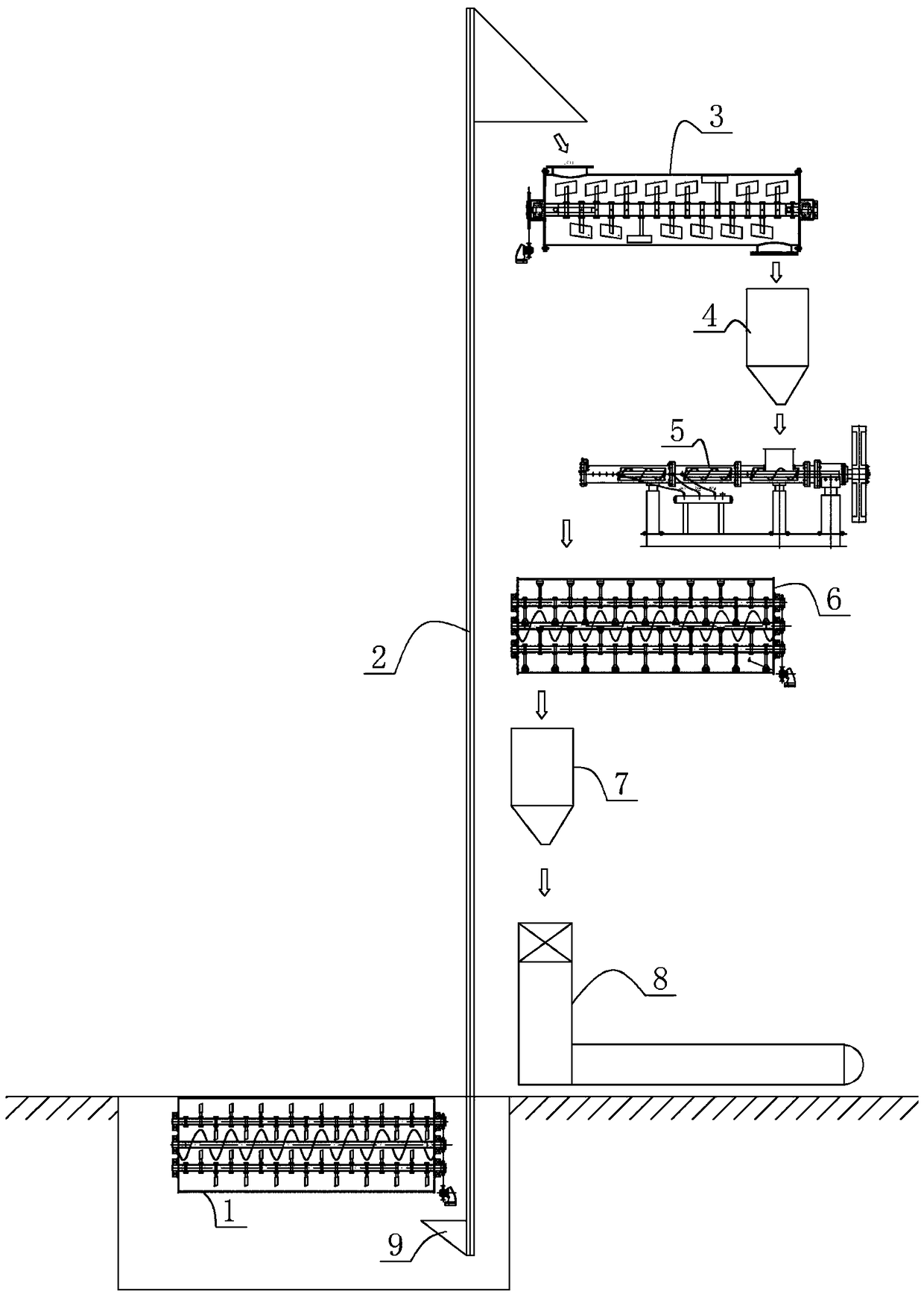

[0019] Such as figure 1 As shown, the schematic diagram of the processing system of paper tree, caragana, protein mulberry and straw feed of the present invention is provided, which consists of a shearing machine 1, a hoist 2, a mixer 3, a first buffer bin 4, and a blasting machine. The puffing machine 5, the conditioning machine 6, the second buffer bin 7 and the packing machine 8 are composed, and the shearing machine 1 is arranged under the ground so as to dump the materials to be processed into the shearing machine 1. The lower end of the elevator 2 is located at the outlet of the shearer 1, and the elevator 2 is provided with a lifting bucket 9, which is used to lift the material discharged from the shearing machine 1 to its top. The mixer 3, the first buffer bin 4, the explosion-explosion extruder 5, the tempering machine 6, the second buffer bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com