Tobacco toasting device and tobacco pre-heating method thereof

A technology in flue-cured tobacco and device, which is applied in the field of flue-cured tobacco device and tobacco preheating, which can solve the problems of affecting taste, loss of taste, wetting tobacco, etc., and achieves the effects of convenient processing and assembly, improving cigarette taste and increasing air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

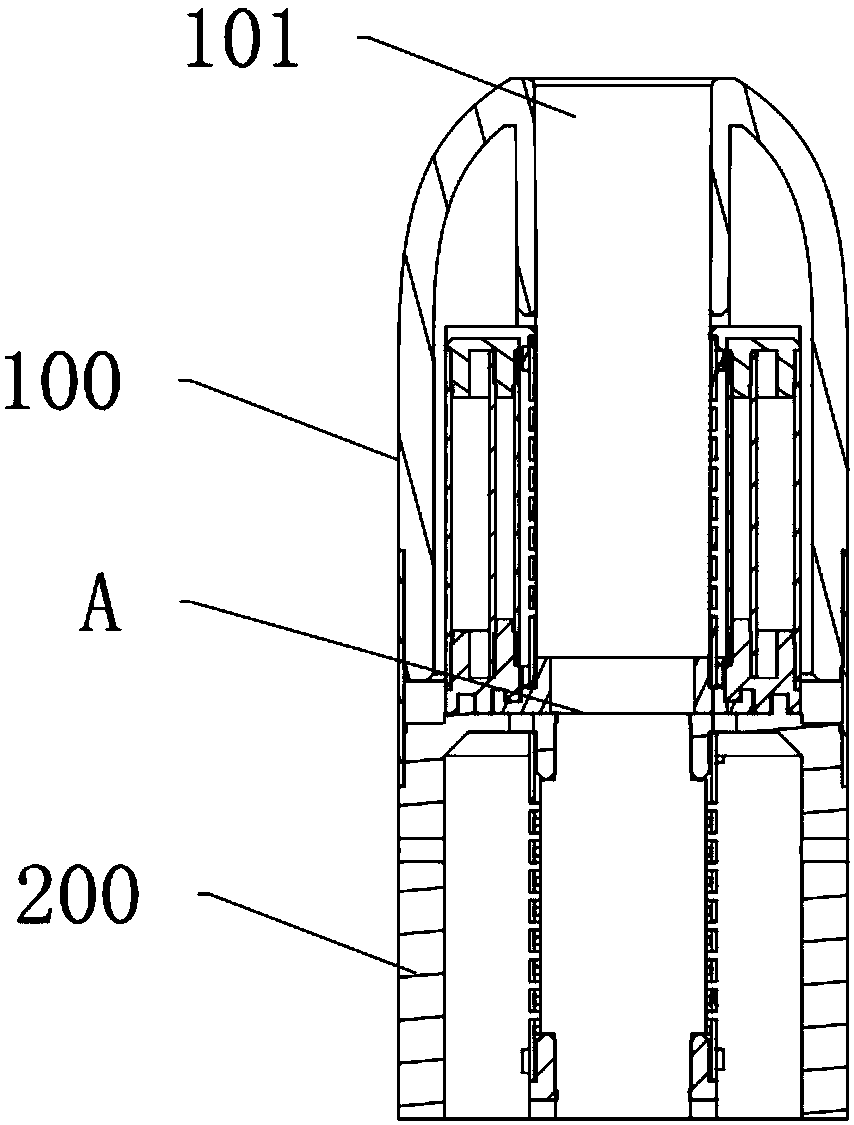

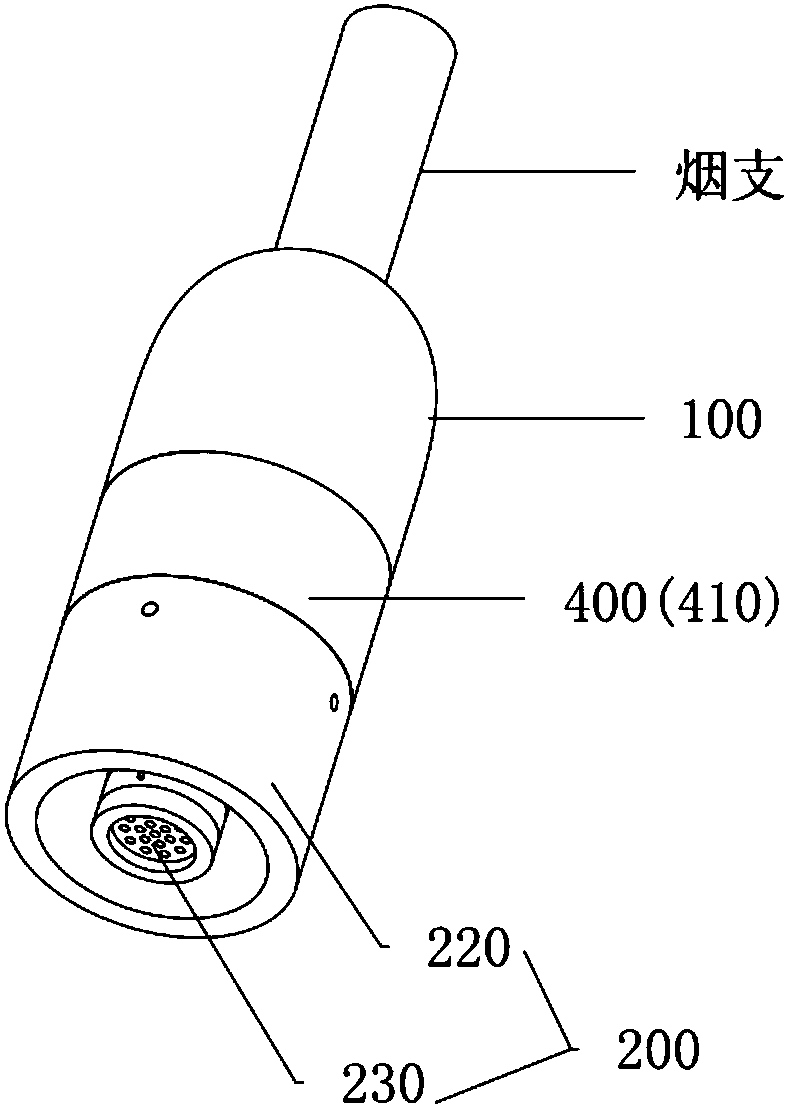

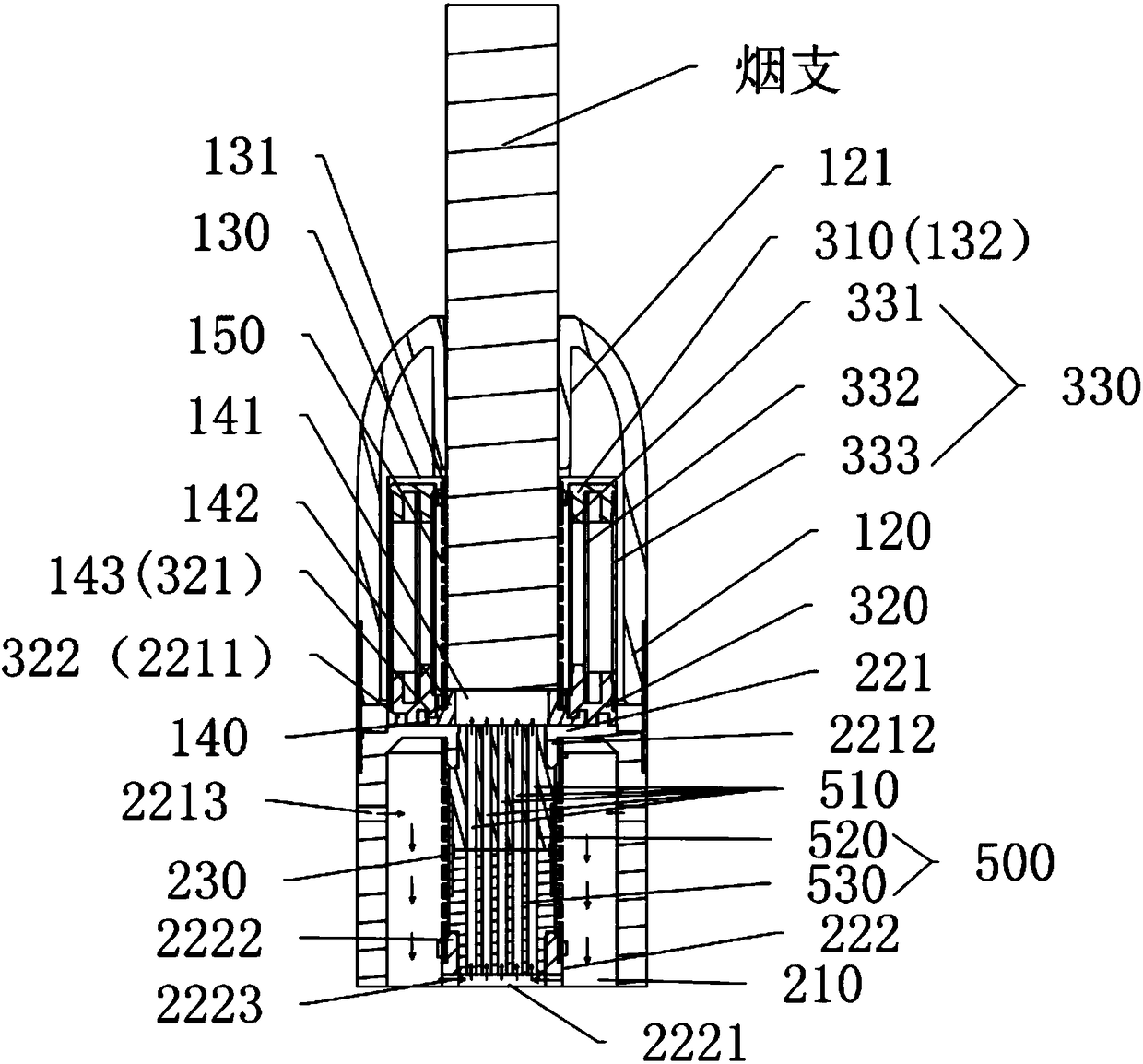

[0058] Such as image 3 As shown, the heating body 100 (see figure 1 ) includes a housing 120, a heating assembly and a thermal insulation assembly. The heating assembly includes an upper cover 130, a base 140, and a heating element 150. One end of the casing 120 is reduced in diameter to form a bent portion 121, and the bent portion 121 surrounds the cigarette insertion port 101 (see figure 1 ), one end of the bent portion 121 is connected with the upper cover 130 , one end of the heating element 150 is inserted in the upper cover 130 , and the other end of the heating element 150 is connected with the base 140 . The heating body 100 also includes a heat insulation assembly arranged outside the heating element 150. The heat insulation assembly includes an upper heat insulation seat 310, a lower heat insulation seat 320 and a heat insulation member 330. The upper heat insulation seat 310 is arranged in the upper cover 130, and the lower heat insulation seat 310 The heat insu...

Embodiment 2

[0075] The differences between Embodiment 2 and Embodiment 1 are as follows: 1. The diverter assembly 500 is not provided in Embodiment 2; 2. The structure of the base 222 is different;

[0076] Such as Figure 10 As shown, in this embodiment, the base 222 is also connected to one end of the top cover 221 . In this embodiment, the base 222 is sheathed on one end of the top cover 221 and is interference fit with the top cover 221 . The top cover 221 is provided with a first through hole 2215, the top cover 221 protrudes toward the direction of the base 222 to form a first protrusion 2212, and the first through hole 2215 runs through the first protrusion 2212; Set on the first protrusion 2212; the base 222 protrudes toward the direction of the top cover 221 to form a second boss 2224, and the other end of the preheating element 230 is sleeved outside the second boss 2224, and the second boss The platform 2224 extends into the inner cavity of the preheating element 230 , and th...

Embodiment 3

[0079] The difference between the third embodiment and the first embodiment lies in the structure of the preheating assembly 200 .

[0080] Such as Figure 11 As shown, the preheating assembly 200 also includes a preheating sleeve 231 pre-set outside the preheating element 230, the inner cavity of the preheating sleeve 231 is the preheating cavity 210; the top cover 221 is away from the insulation The preheating sleeve 231 is connected to one side of the heating assembly, and the base 222 is connected to the end of the preheating sleeve 231 away from the top cover 221 . Specifically, the top cover 221 is provided with a first through hole 2215, the top cover 221 protrudes toward the direction of the base 222 to form a first protrusion 2212, and the first through hole 2215 runs through the first protrusion 2212; preheating One end of the sleeve 231 is sleeved on the first protrusion 2212; the base 222 is provided with a second through hole 2221, and the base 3222 protrudes tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com