Medical orthopedic steel plate with controllable continuous locking and pressurizing functions

A steel plate and orthopaedic technology, applied in the field of new orthopaedic steel plates, can solve the problems of inability to ensure compression and closure, inability to pressurize the fracture end, and increase the fracture gap, so as to maintain the length of the bone, ensure stress stimulation, and promote fracture healing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

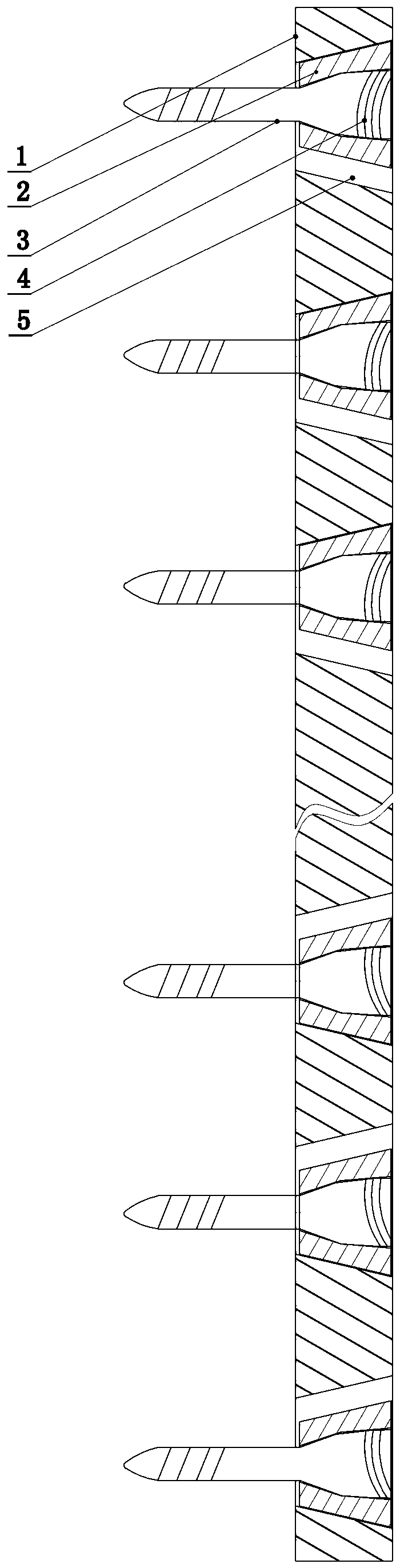

[0030] All the screws 3 at both ends of the steel plate are installed on the sliding pressure pad 2 which can slide to realize sliding pressure.

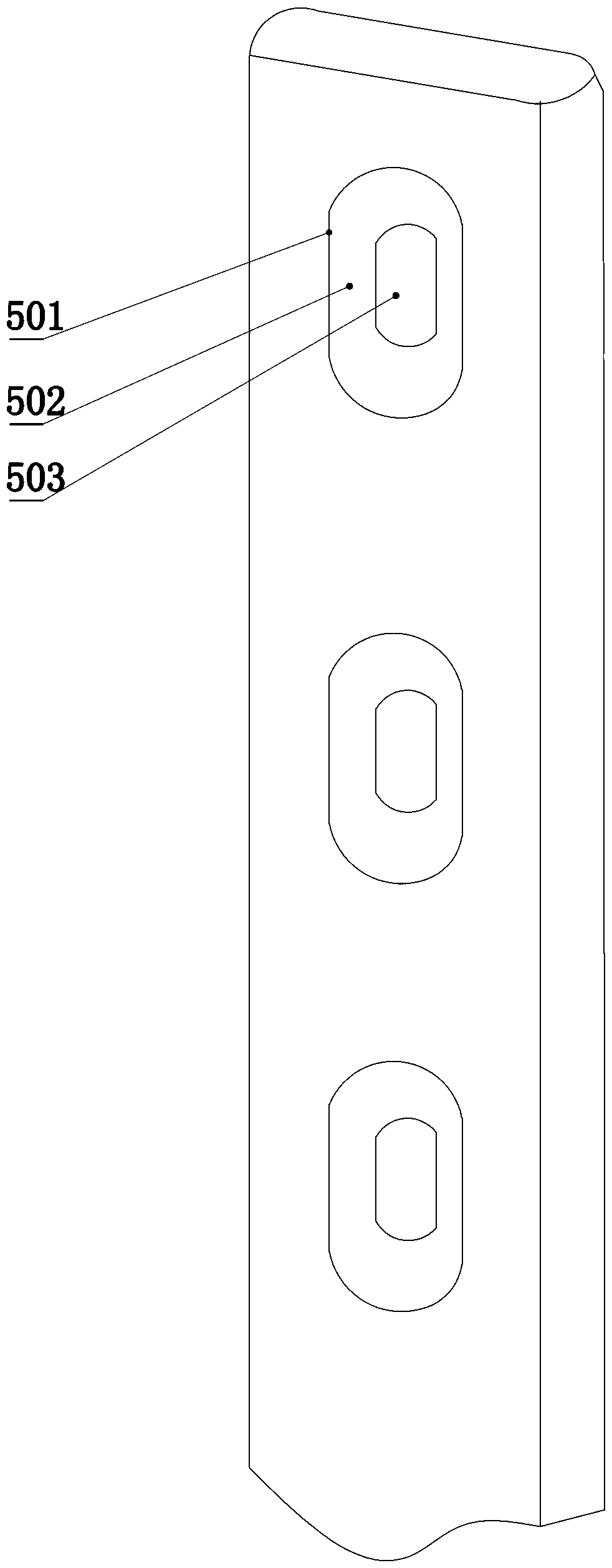

[0031] When in use, all sliding compression pads 2 should be installed at the far end of the compression chute, such as Image 6 As shown, the upper or lower end surface of the sliding pressing pad is in close contact with the upper or lower end surface of the pressing chute 5. The distal end refers to the end of the compression chute away from the fracture site 7. Such as Figure 5 During the operation, a one-time compression reduction is adopted during the operation, and steel plate is used for fixation; after the bone resorption of the fractured end after the operation, the sliding compression pad will slide towards the fracture site under the action of muscle tissue tension or body gravity compression.

[0032] It should be noted that the aforementioned pressing distance should be equal to the sum of the sliding gaps of the upper and ...

Embodiment 2

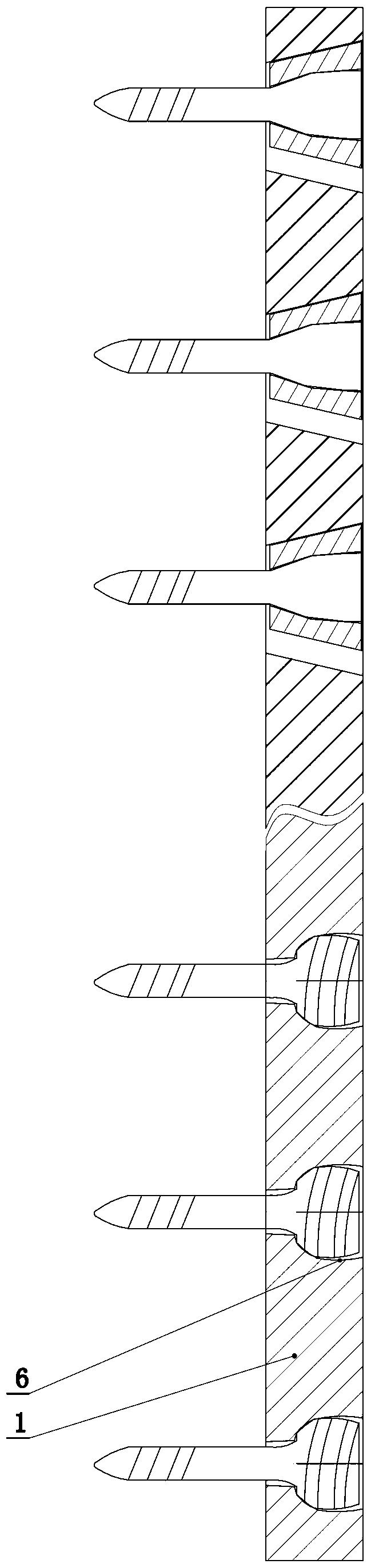

[0034] All the screws 3 at one end (upper end or lower end) of the upper and lower ends are installed on the pressure chute 5 by sliding the pressure pad 2.

[0035] The usage method is basically the same as in the first embodiment. All sliding compression pads 2 should be installed at the far end of the compression chute. The upper end surface of the sliding pressing pad is in close contact with the upper end surface of the pressing chute 5. During the operation, a one-time compression reduction was used during the operation, and plate fixation was adopted; after the bone resorption of the fractured end occurred after the operation, the screw 3 in the screw mounting hole 6 could not move under the action of the muscle tissue tension or the gravity pressure of the body, and the bones caused the sliding increase. The pressure pad will slide towards the fracture site.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com