Horizontal-type dynamic variation fettling device

A dynamic transformation and blank trimming technology, which is applied to auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of low work efficiency and high labor intensity, achieve compact structure, high work reliability, and improve blank trimming. The effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

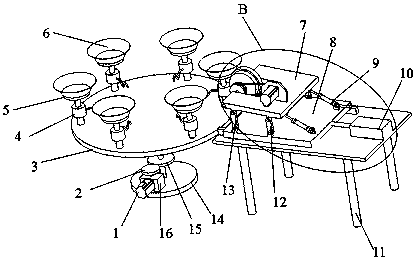

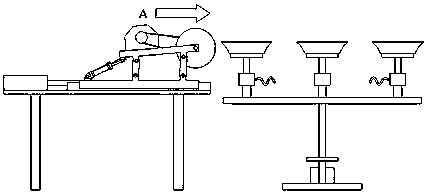

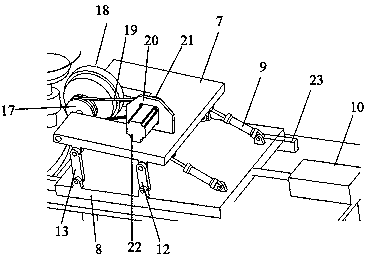

[0019] control figure 1 —2. Before the device starts to work, the turntable motor 1 and trimming motor 22 are in a power-off state, and the piston rod of the translation cylinder 10 is retracted, so that the moving plate 8 moves along the guide rail 23 to a direction away from the turntable 3. The bowl blank 6 is placed on the pallet 5 upper side on the pallet motor 4 fixed on the turntable 3, and the system completes the preparatory work before work.

[0020] Then the device works, the turntable motor 1 starts, the turntable motor 1 drives the reducer 16 to rotate, the output shaft end of the reducer 16 is connected to the pinion 21, the pinion 21 meshes with the turntable gear 15 and drives the turntable 3 to rotate, when the bowl blank on the turntable 3 6. When it is shifted to the front of the blank trimming mechanism, the translation cylinder 10 acts, and its piston rod drives the moving plate 8 to move forward along the guide rail 23, and then the blank trimming motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com