Continuous fiber reinforced composite material 3D printer spray head and printer

A technology of reinforcing composite materials and continuous fibers, applied in the field of additive manufacturing, can solve the problems of inability to bond fiber filaments together, easy plugging, fiber filament blocking the nozzle, etc., and achieve the effect of eliminating the blocking of printing nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

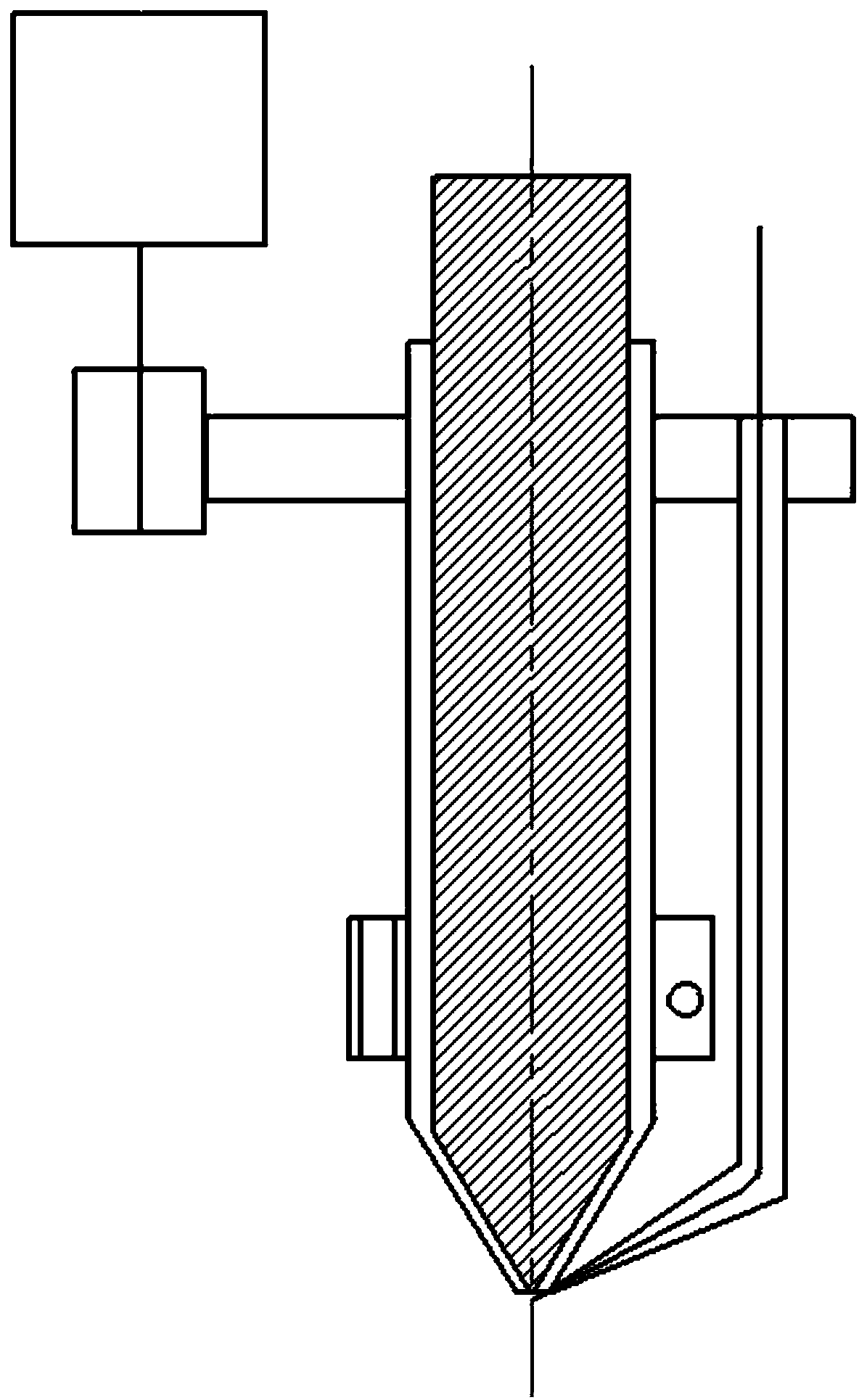

[0033] Combine below Figure 1-6 To illustrate this embodiment, the present invention belongs to the field of additive manufacturing, and more specifically, relates to a continuous fiber reinforced composite material 3D printing nozzle, which consists of a wire extrusion device, a heating device, a temperature measuring device, a feeding pipe with openings at both ends, and a feeding pipe. Composed of fiber pipes and power devices, it can effectively prevent the phenomenon of fiber filaments blocking the nozzle; in addition, it can also prevent the molten resin material from overflowing.

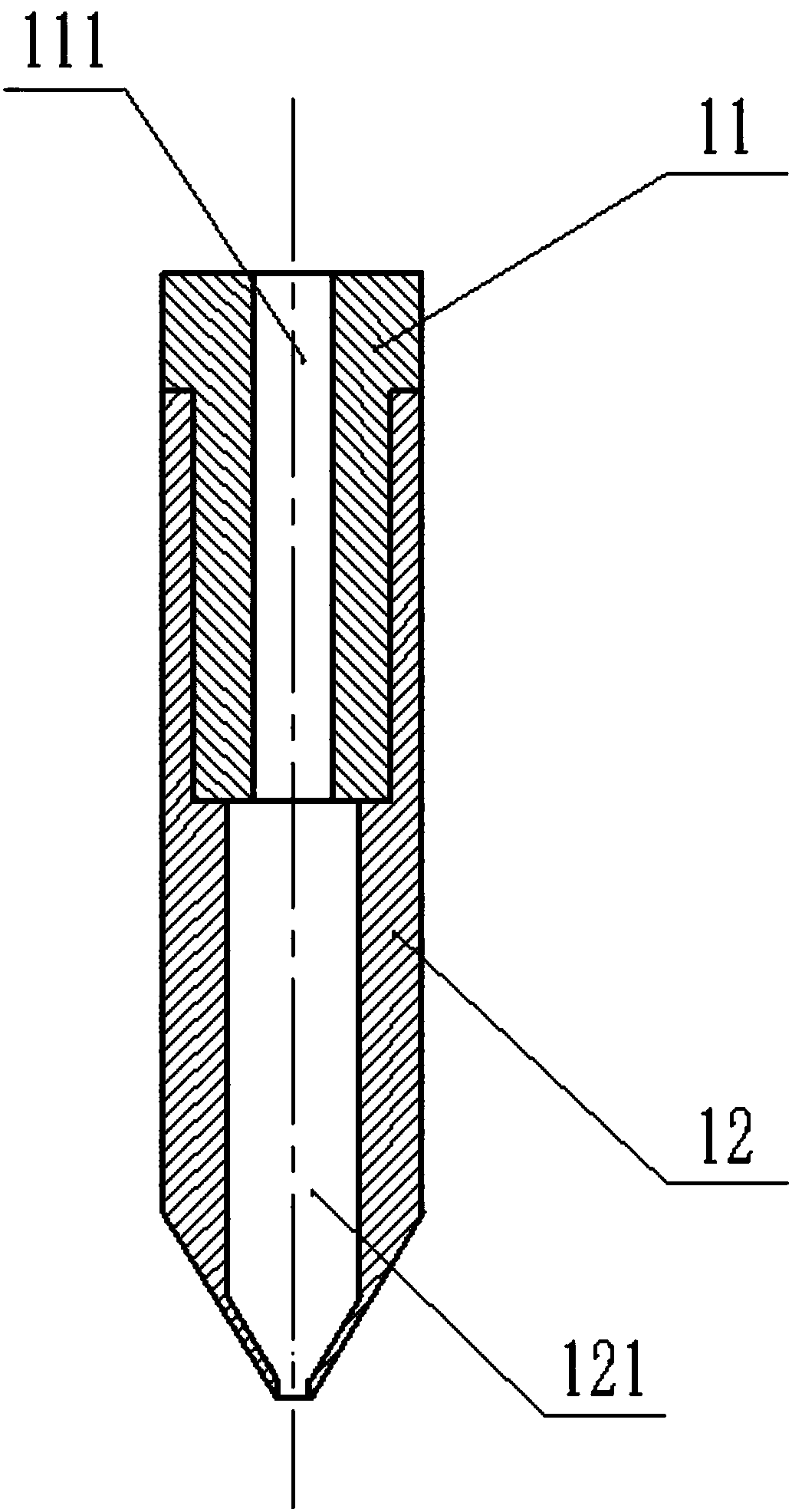

[0034] The inside of the feeding pipeline is provided with a cavity for containing resin materials, and the cavity communicates with the openings at both ends of the feeding pipeline; the feeding pipeline can be a cylindrical pipeline, and the cavity set inside it is coaxial with the feeding pipeline. Both the upper end and the lower end are open for resin material entry and extrusion.

[0...

specific Embodiment approach 2

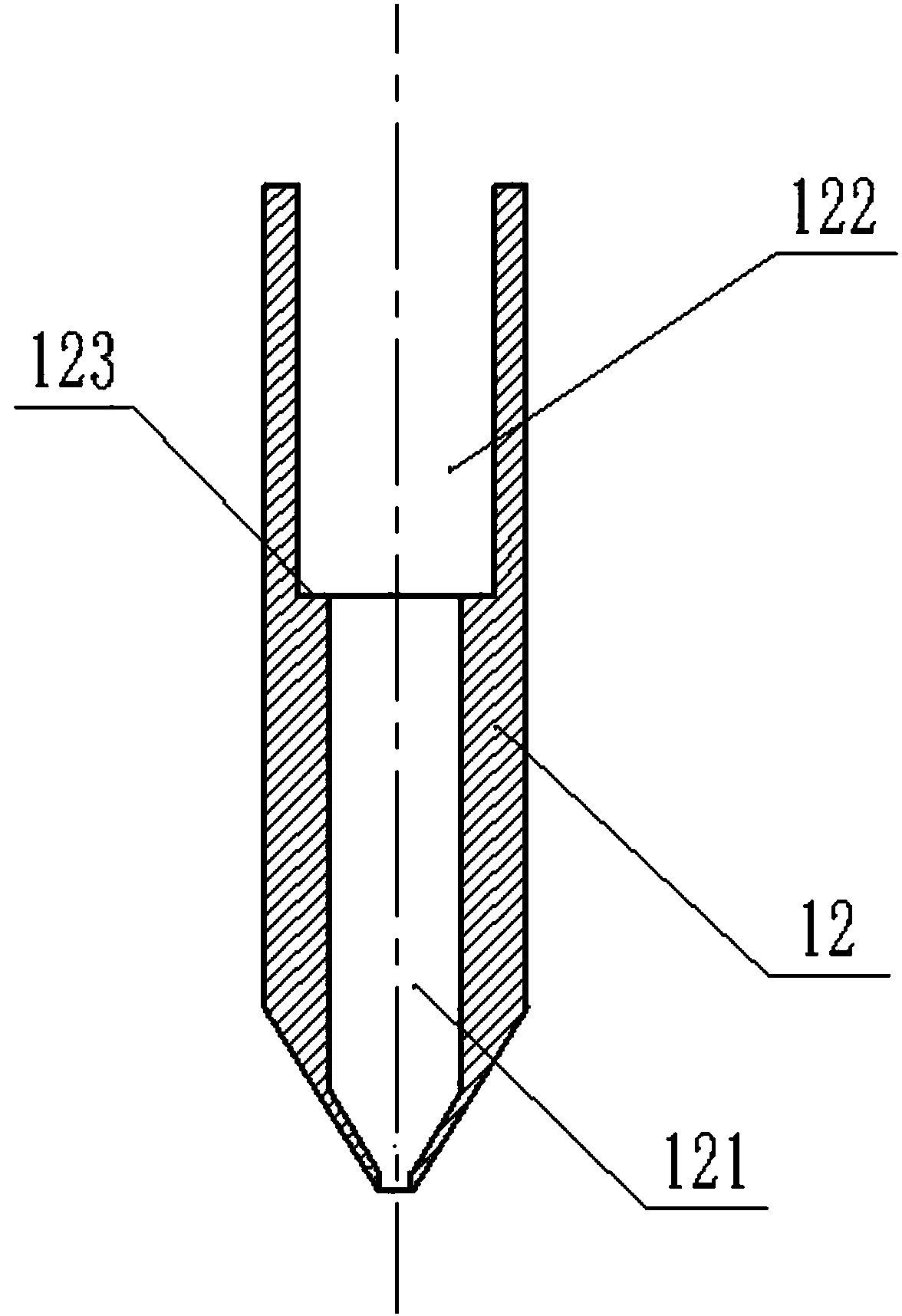

[0038] Combine below Figure 1-6 Describe this embodiment, this embodiment will further explain Embodiment 1, the wire feeding pipeline is composed of a vertical pipeline and an inclined pipeline, the vertical pipeline and the inclined pipeline are connected and form an L shape, the vertical pipeline and the inclined pipeline The included angle between the pipes is greater than 90° and less than 180°. The vertical pipe and the inclined pipe can be an integral structure or both are fixedly connected, and the axis of the vertical pipe is parallel to the axis of the feeding pipe. The inclined pipe is inclined towards the outlet of the feeding pipe, so that the inclined pipe will not interfere with the printed object or the workbench.

specific Embodiment approach 3

[0039] Combine below Figure 1-6 This embodiment is described, and this embodiment is a further description of the second embodiment. The inclined pipe is a tapered pipe and the outlet end is the end with a smaller aperture, so that the inclined pipe will not interfere with the printed object or the workbench.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap