Device and method for coupling micro-alkaline and micro-aerated anaerobic fermentation of sludge with SBR nitrogen and phosphorus removal and sludge reduction

A technology of sludge anaerobic fermentation, denitrification and phosphorus removal, applied in water/sludge/sewage treatment, chemical instruments and methods, aerobic and anaerobic process treatment, etc. Treatment and reduction of sludge discharge from SBR denitrification and phosphorus removal units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

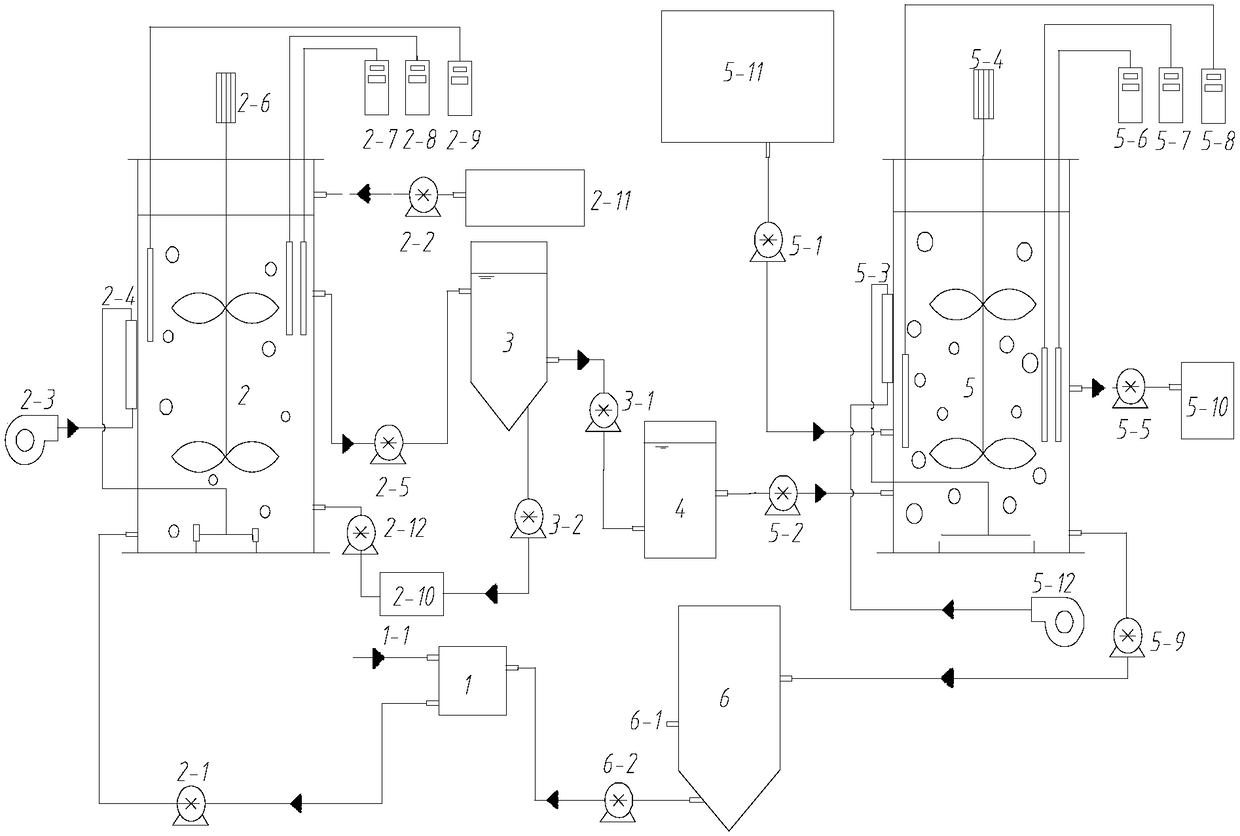

[0026] The volume of the sludge anaerobic fermentation micro-alkaline and micro-aeration device is 10L, and the SBR denitrification and phosphorus removal device is 10L. The influent of the SBR denitrification and phosphorus removal device is a mixture of domestic sewage and fermentation liquid, and its influent index is COD=300-350mg / L, NH 4 + -N=60-70mg / L, PO 4 3- -P=5-10mg / L.

[0027] Sludge anaerobic fermentation micro-alkaline micro-aeration device (2), control sludge concentration MLSS=9000-10000mg / L, SCOD=30-40mg / L, control fermentation pH=9.0-9.5, temperature 20-30°C, Sludge age SRT=8-10d; start-up success marks SCOD=1500-2000mg / L, SCFAs=1000-1400mgCOD / L, NH 4 + -N=150mg / L;

[0028] SBR denitrification and phosphorus removal device (5), sludge concentration MLSS=3000-4000mg / L, COD=30-40mg / L, temperature 20-30°C, pH=6.5-7.5; the sign of successful startup is the system effluent COD =30-50mg / L, NH 4 + -N=1-5mg / L, TN=5-15mg / L, PO 4 3- -P=0.1-0.5mg / L;

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com