Process and system for producing methacrylonitrile through fractional-step ammoxidation reaction

A technology of ammoxidation reaction and methacrylonitrile, which is applied in the field of catalytic ammoxidation, can solve the problems of difficult treatment, low selectivity, and many by-products, and achieve the effects of stable product quality, sufficient reaction, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

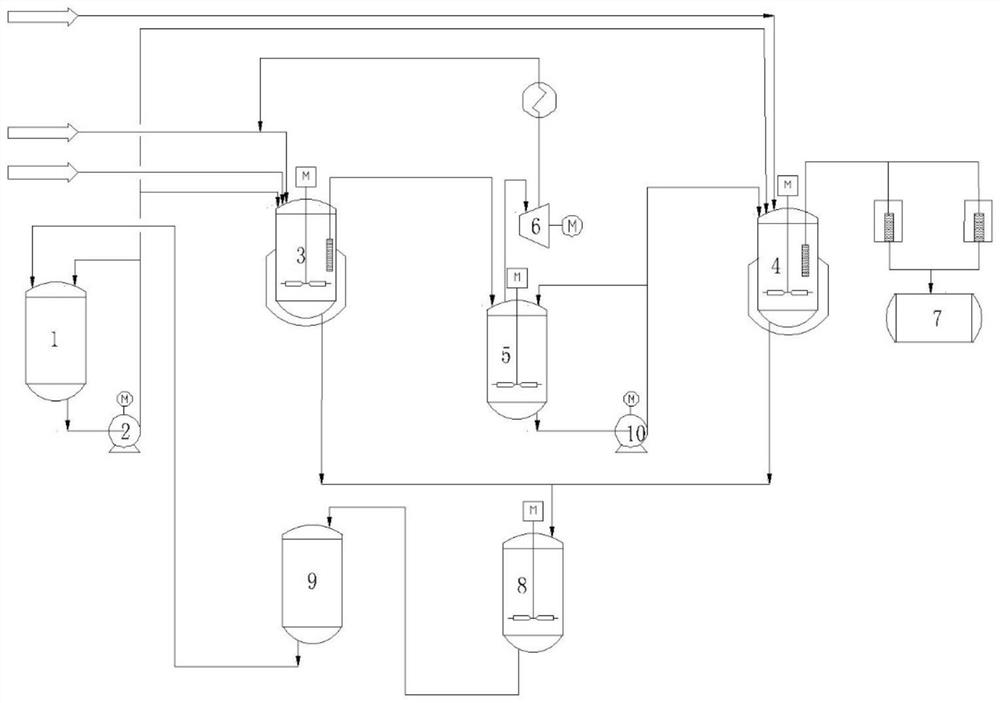

[0030] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0031] see figure 1 , the system of the present invention comprises the first filter-type stirred reactor 3, the gas-liquid separation tank 5, the feed pump 10, the second filter-type stirred reactor 4 and the reactor discharge tank 7 connected in sequence, wherein the first filter Type stirred reactor 3 is provided with ammonia gas inlet, raw material inlet and catalyst inlet, described second filtering type stirred reactor 4 is provided with oxygen or air inlet, reaction liquid inlet and catalyst inlet, the gas phase of described gas-liquid separation tank 5 The outlet is connected to the ammonia gas inlet of the first filter-type stirred reactor 3 through the ammonia gas compressor 6 , and the liquid phase outlet of the gas-liquid separation tank 5 is connected to the reaction liquid inlet of the second filter-type stirred reactor 4 .

[0032] Catalyst outlets at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com