A method for preparing α-type high-strength gypsum from phosphogypsum dihydrate

A technology of phosphogypsum dihydrate and high-strength gypsum, which is applied in the field of α-type high-strength gypsum, can solve the problems of high energy consumption and high economic cost, and achieve the effects of improving recovery, mitigating pollution, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

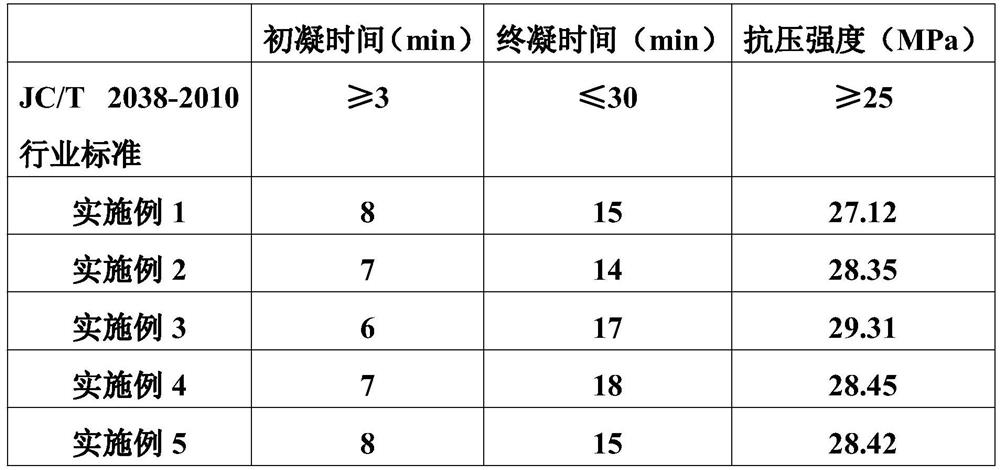

Examples

Embodiment 1

[0026] A method for preparing α-type high-strength gypsum from phosphogypsum dihydrate, comprising the following steps:

[0027] (1) slurry preparation: take by weighing 60g phosphoric acid solution (P 2 o 5 Mass concentration is 29%), 1g of sulfuric acid (98%), 40g of phosphogypsum dihydrate, mixed and stirred evenly to make slurry;

[0028] (2) Preparation of gypsum seed crystals: Stir the slurry in step (1) and raise the temperature to 95° C., and keep it warm for 170 minutes.

[0029] (3) Preparation of α-type high-strength gypsum: re-prepare the slurry according to the method of step (1), stir the slurry and heat it to 95°C, then add gypsum seed crystals according to the mass percentage of gypsum in the slurry to 10%, and keep warm for 200min. After the slurry is filtered, the filter residue is washed with 95°C hot water until neutral, and the filter residue is dried to obtain α-type high-strength gypsum.

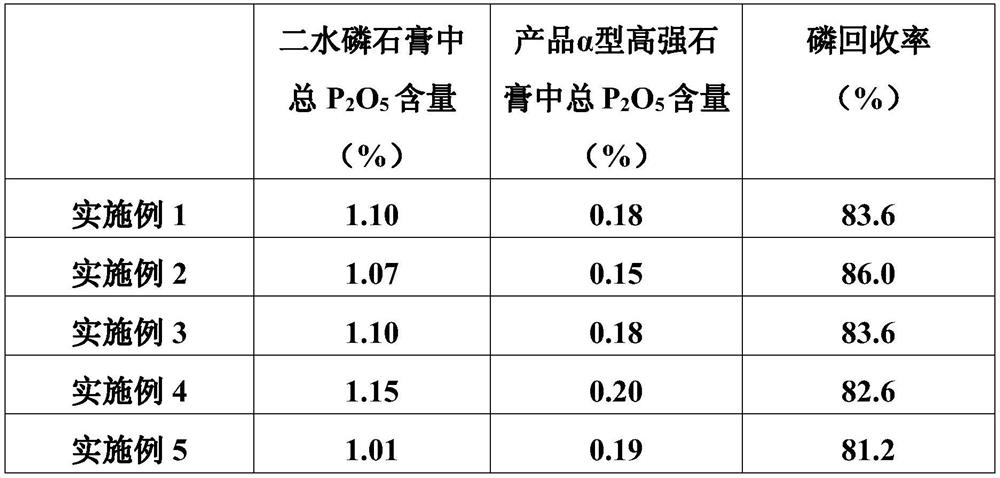

[0030] Raw material dihydrate phosphogypsum performance index:...

Embodiment 2

[0033] A method for preparing α-type high-strength gypsum from phosphogypsum dihydrate, comprising the following steps:

[0034] (1) slurry preparation: take by weighing 70g phosphoric acid solution (P 2 o 5 The mass concentration is 31%), 4g of sulfuric acid (98%), 30g of phosphogypsum dihydrate, mixed and stirred evenly to make a slurry;

[0035] (2) Preparation of gypsum seed crystals: Stir the slurry in step (1) and raise the temperature to 95° C., and keep it warm for 200 minutes.

[0036] (3) Preparation of α-type high-strength gypsum: re-prepare the slurry according to the method of step (1), stir the slurry and heat it to 96°C, then add gypsum seed crystals according to 30% of the mass percentage of gypsum in the slurry, and keep warm for 180min. After the slurry is filtered, the filter residue is washed with 95°C hot water until neutral, and the filter residue is dried to obtain α-type high-strength gypsum.

[0037] Product performance indicators: total P 2 o 5 C...

Embodiment 3

[0039] A method for preparing α-type high-strength gypsum from phosphogypsum dihydrate, comprising the following steps:

[0040] (1) slurry preparation: take by weighing 75g phosphoric acid solution (P 2 o 5 Mass concentration is 32%), 5g sulfuric acid (98%), 25g phosphogypsum dihydrate, mix and stir evenly and make slurry;

[0041] (2) Preparation of gypsum seed crystals: Stir the slurry in step (1) and raise the temperature to 90° C., and keep it warm for 200 minutes.

[0042] (3) Preparation of α-type high-strength gypsum: re-prepare the slurry according to the method in step (1), stir the slurry and heat it to 97°C, then add gypsum seed crystals according to 50% of the mass percentage of gypsum in the slurry, and keep warm for 180min. After the slurry is filtered, the filter residue is washed with 95°C hot water until neutral, and the filter residue is dried to obtain α-type high-strength gypsum.

[0043] Product performance indicators: total P 2 o 5 Content 0.18%, stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com