Method for directly liquefying coal and biomass

A biomass and direct technology, applied in the field of coal and biomass co-smelting process, can solve the problems of low liquefaction efficiency, limited coal powder content, unrealized coal, biomass and oil mixing production technology, etc., to achieve fluidity High, reduce hydrogen consumption, and achieve clean and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

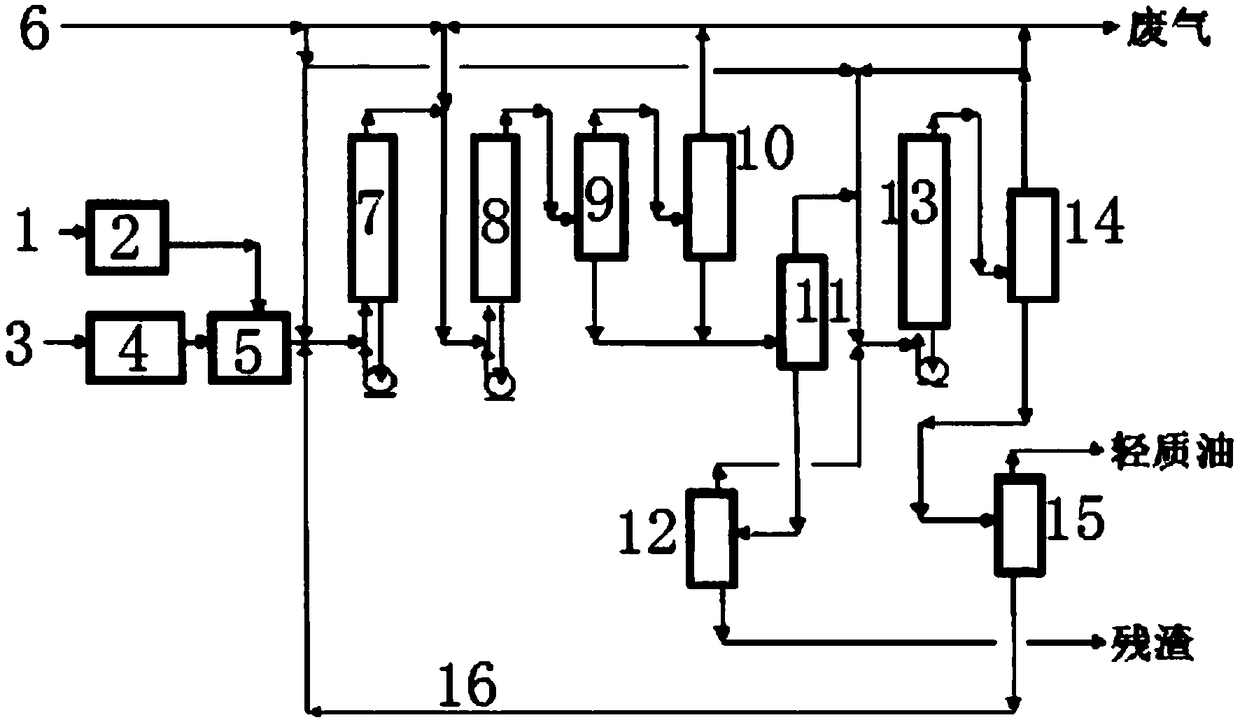

Method used

Image

Examples

Embodiment 1

[0087] The method for direct liquefaction of coal and biomass provided in this embodiment comprises the following steps:

[0088] Pretreatment of biomass raw materials:

[0089] (1) Take wheat stalks, dry and dehydrate them, and then send them to a jet mill for crushing to obtain primary crushed wheat stalks with a particle size of D 50 is 200 μm.

[0090] (2) Sending the primary crushed material of wheat straw into a briquetting machine or a plodder for extrusion molding with a molding pressure of 3 MPa to obtain a compressed material of wheat straw.

[0091] (3) Send the wheat straw compressed material into the jet mill for secondary crushing to obtain the secondary crushed material of wheat straw, particle size D 50 40 μm, set aside.

[0092] Pretreatment of coal raw materials:

[0093] (1) Take Shendong long-flame coal, dry and dehydrate it, and then send it to a ball mill for crushing to obtain primary crushed material of Shendong long-flame coal, particle size D ...

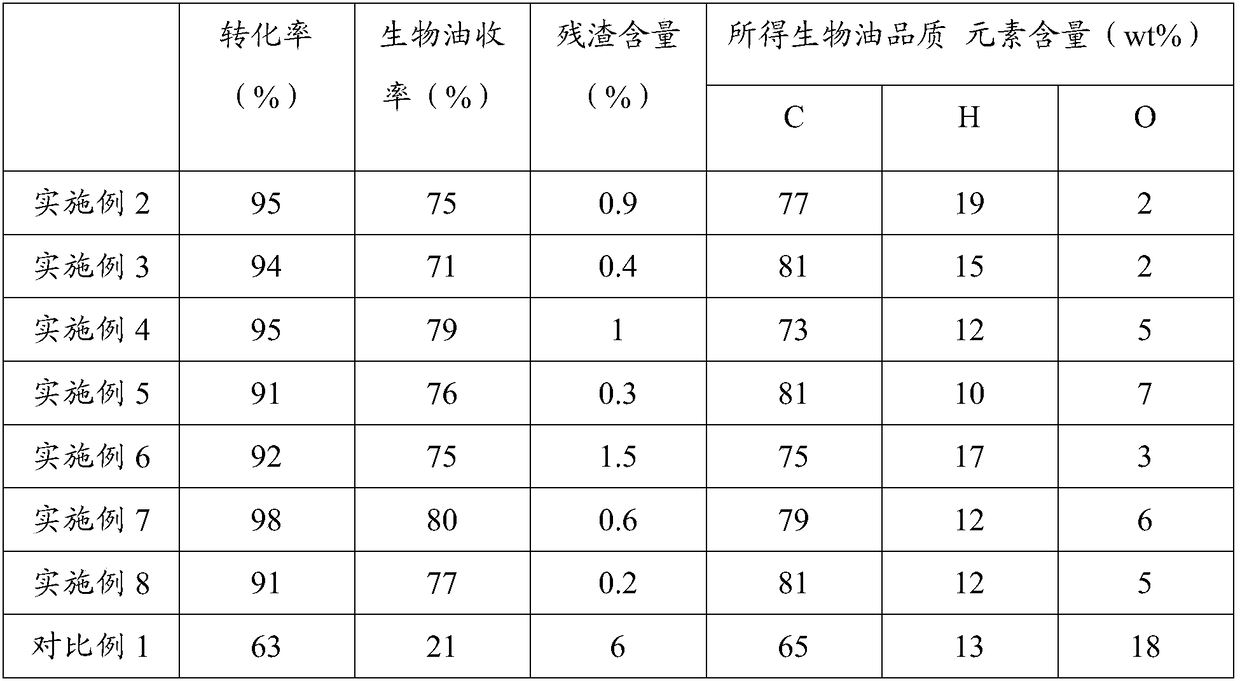

Embodiment 2

[0108] The method for direct liquefaction of coal and biomass provided in this embodiment comprises the following steps:

[0109] Pretreatment of reeds:

[0110] (1) Take the reed, dry and dehydrate it, crush it to a median particle size of 300 μm, and then send it to a briquetting machine or a plodder for extrusion molding at a molding pressure of 0.5 MPa to obtain a compressed reed material.

[0111] (2) Send the compressed reed material into a hammer mill for crushing to obtain crushed reed material for use.

[0112] Pretreatment of coal raw materials:

[0113] (1) Get lignite, dry it and dehydrate it, then send it into a briquetting machine for extrusion molding, and the molding pressure is 5MPa to obtain lignite compressed material.

[0114] (2) Send the lignite compressed material into a ball mill for pulverization to obtain the lignite pulverized material for use.

[0115] Preparation of hydrogenation catalyst:

[0116] The hydrogenation catalyst raw material ...

Embodiment 3

[0128] The method for direct liquefaction of coal and biomass provided in this embodiment comprises the following steps:

[0129] Pretreatment of biomass raw materials:

[0130] (1) Get the leaves, dry and dehydrate them, and then send them to the jet mill for crushing to obtain primary crushed leaves with a particle size of D 50 is 200 μm.

[0131] (2) Send the primary pulverized material of the leaves into a briquetting machine or a plodder for extrusion molding with a molding pressure of 3 MPa to obtain compressed leaves.

[0132] (3) The leaf compressed material is sent into the jet mill, and secondary pulverization is carried out to obtain the secondary pulverized material of the leaf, particle diameter D 50 40 μm, set aside.

[0133] Pretreatment of coal raw materials:

[0134] (1) Take Shendong long-flame coal, dry and dehydrate it, and then send it to a ball mill for crushing to obtain primary crushed material of Shendong long-flame coal, particle size D 50 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com