Pulping system for high-humidity-strength waste cardboard paper

A technology for cardboard paper and pulping, applied in pulp beating/refining methods, papermaking, paper recycling, etc., can solve the problems of unfavorable production cost savings, difficult dissociation of fibers, and low utilization rate of raw materials, so as to reduce grinding Reduce pulp energy consumption, improve swelling degree, and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

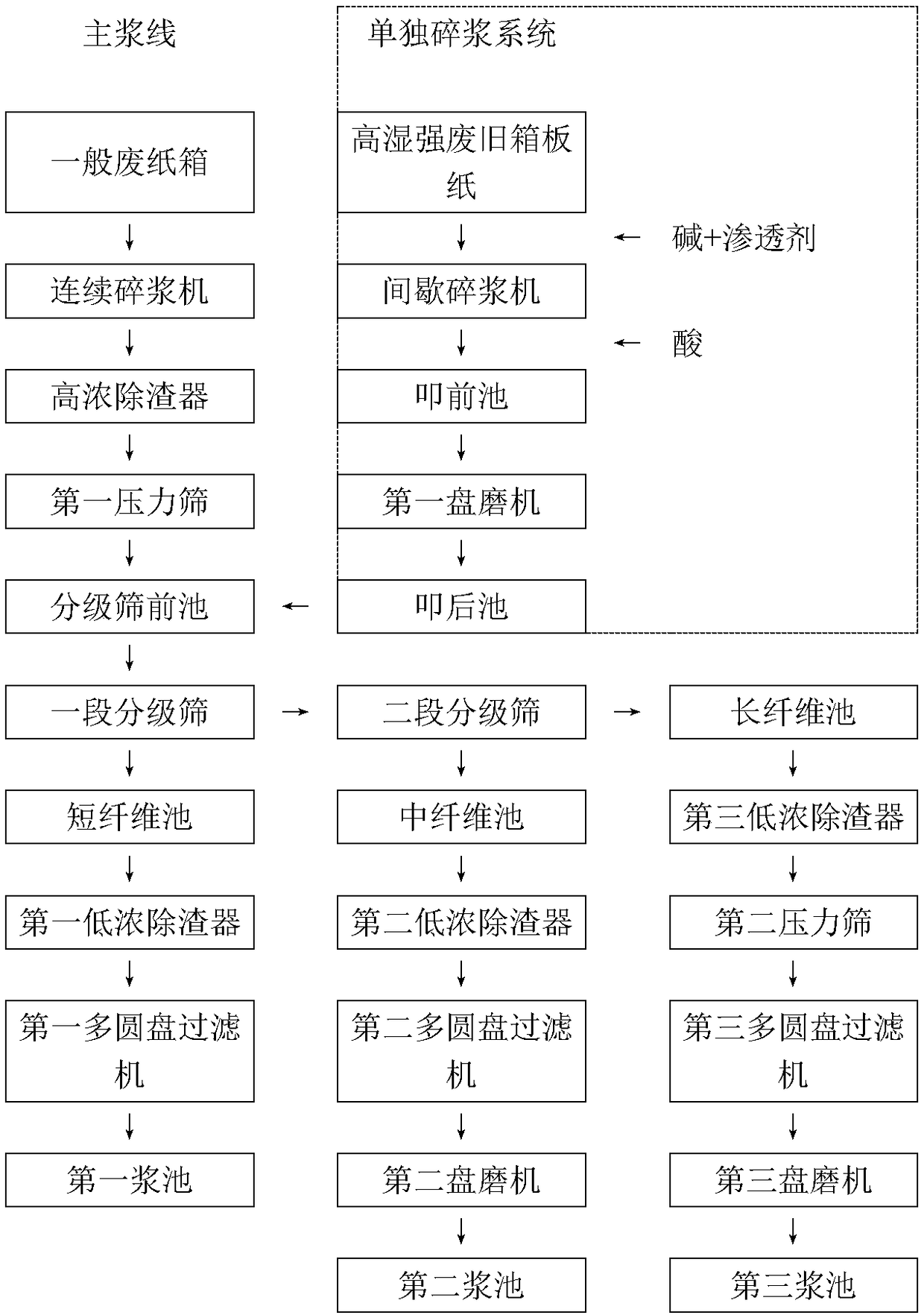

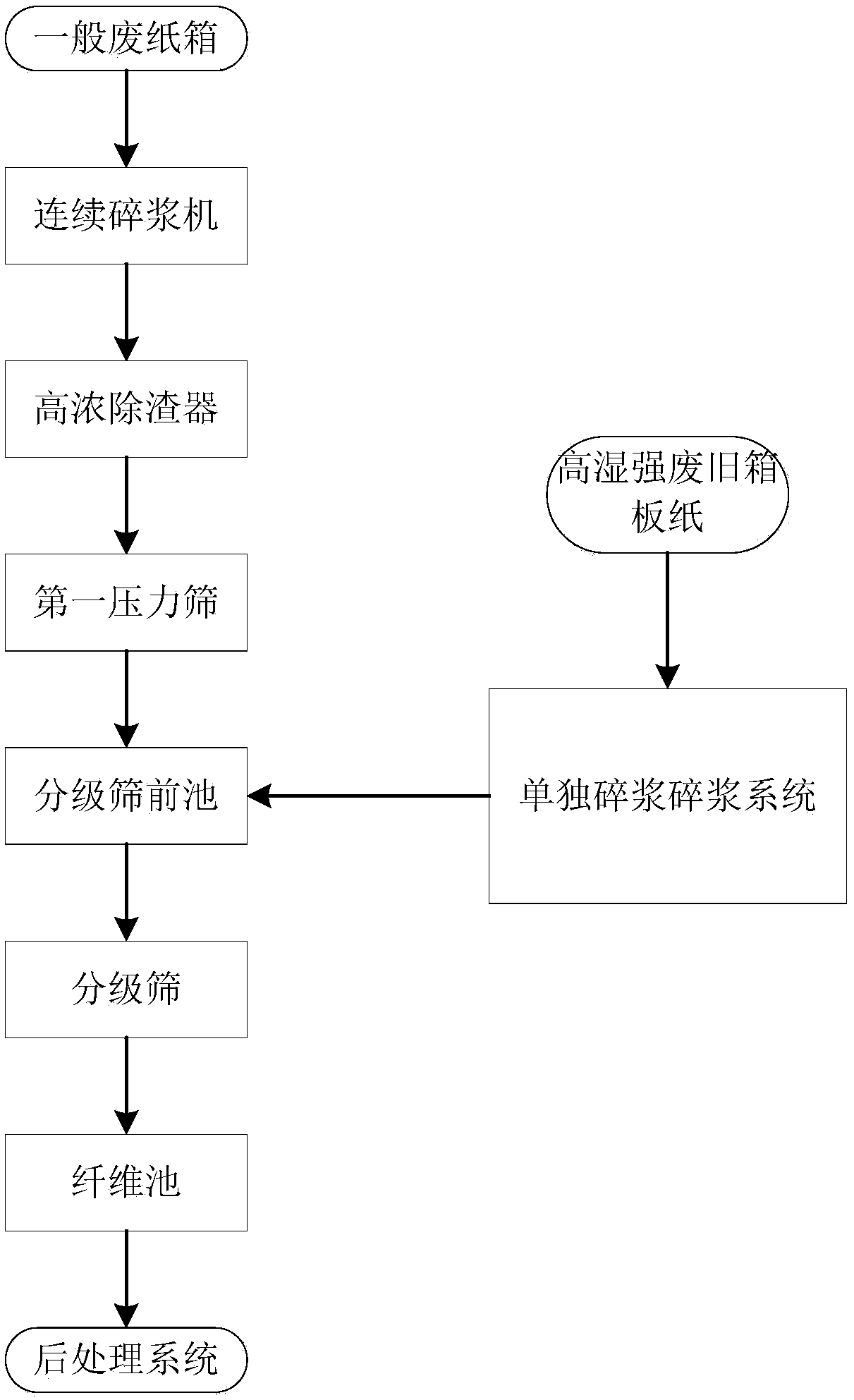

[0028] Such as image 3 As shown, the general waste paper box enters the continuous pulper for pulping to form a slurry; the slurry then enters the high-concentration slag remover to remove the coarse slag in the slurry, and then enters the first pressure screen for screening. Remove relatively small impurities, and then enter the grading screen forebay; the slurry enters the grading sieve from the grading sieve forebay, and the slurry is classified, and the slurry after grading through the grading sieve enters different fiber pools, and different fiber pools The pulp in the pulp enters the post-treatment system, and after being processed by the post-treatment system, the pulp that can be used for papermaking is formed. The high-humidity waste containerboard is pulped by a separate pulping system and then enters the grading screen pool, and the subsequent process is the same as that of ordinary containerboard.

[0029] Wherein, the continuous pulper is a kind of hydraulic pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com