PVC (Polyvinyl Chloride) plastic tube suite

A PVC material and plastic pipe technology, applied in the direction of pipe components, pipes/pipe joints/fittings, siphons, etc., can solve problems affecting construction progress, affecting drainage speed, pipe blockage, etc., and achieve the effect of large construction flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

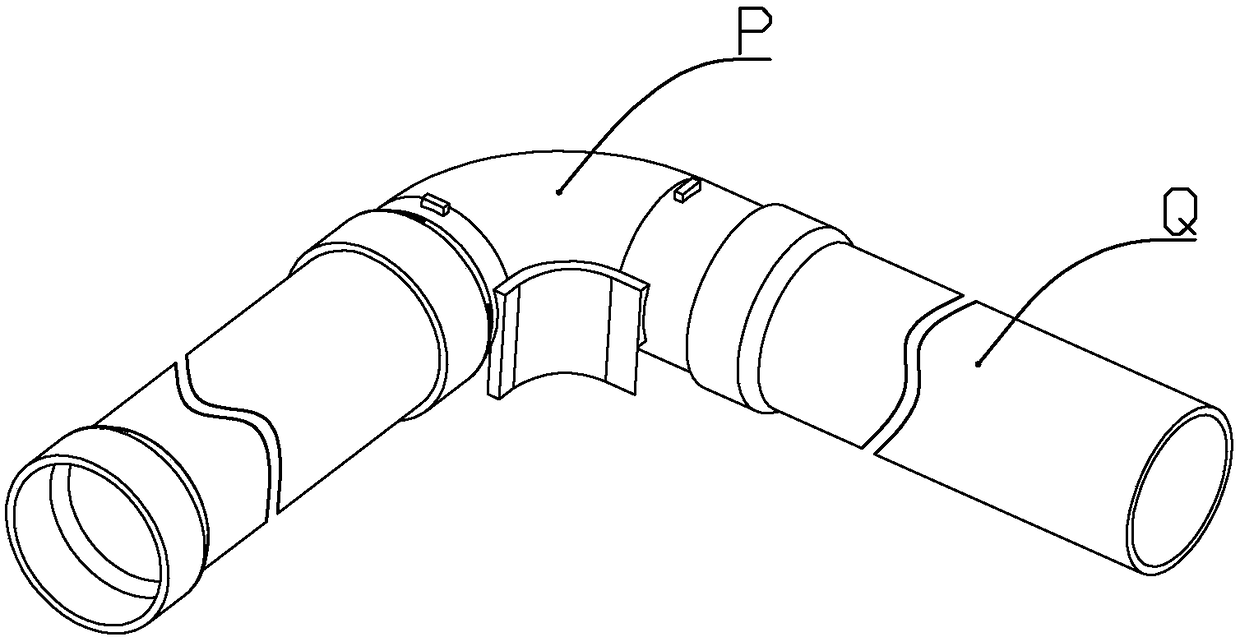

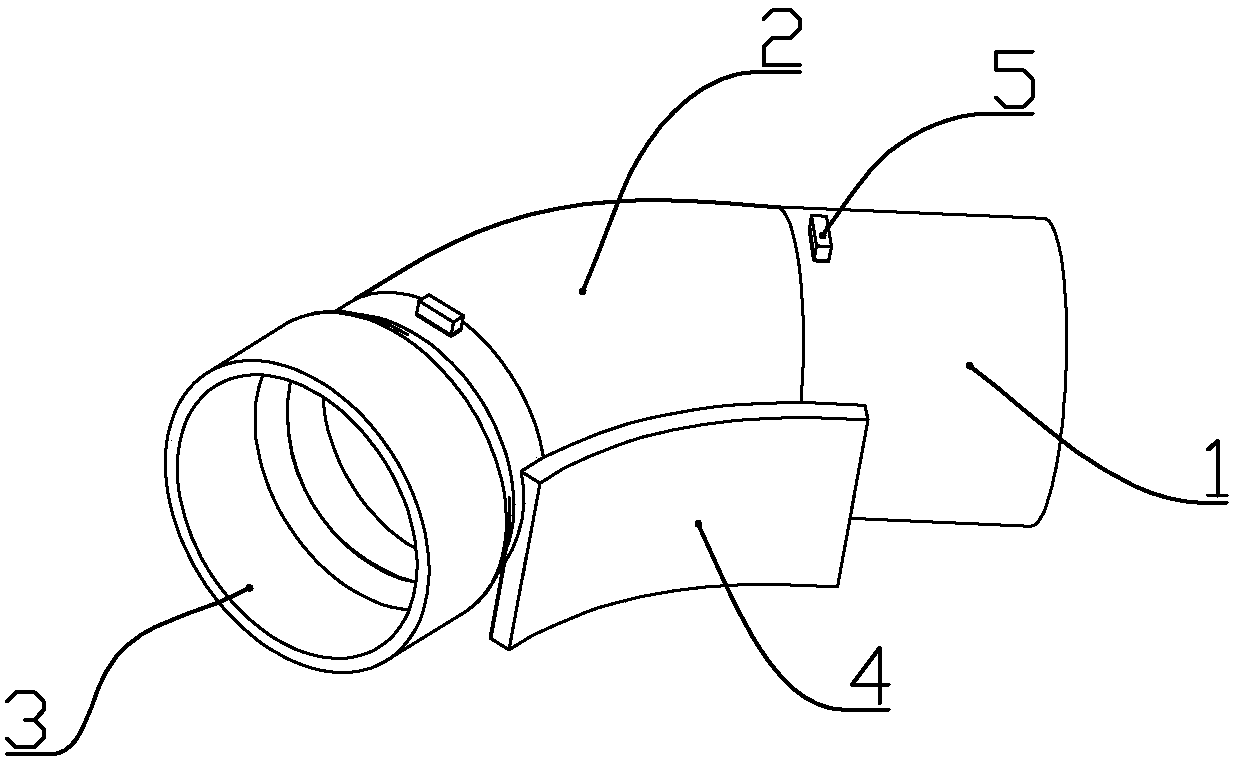

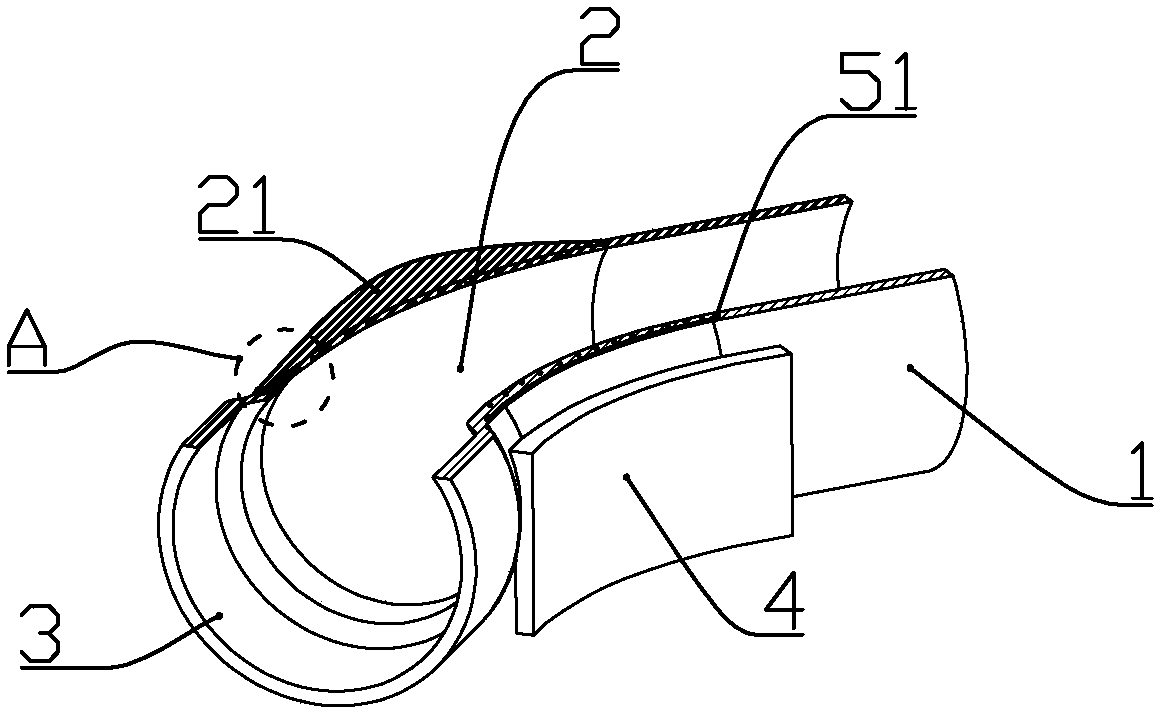

[0073] according to Figure 1 to Figure 6 As shown, a PVC plastic pipe set described in this embodiment includes a straight pipe Q and a connecting pipe P. A socket is formed at one end of the straight pipe, and the inner diameter of the socket is equal to the outer diameter of the straight pipe.

[0074] The connecting pipe includes a socket end 1 , a bent portion 2 and a socket end 3 integrally connected in sequence; the outer diameter of the socket end and the inner diameter of the socket end are equal to the outer diameter of the straight pipe.

[0075] In the initial state of the connecting pipe, the angle between the axial direction of the socket end and the socket end is 160-175°;

[0076] The bending part includes an inner pipe part 201 and an outer pipe part 202 located outside the inner pipe part; the socket end, the inner pipe part and the socket end of the connecting pipe are integrally injection-molded by conventional PVC materials, and the inner pipe A helical s...

Embodiment 2

[0081] This embodiment makes further limitations and descriptions on the basis of embodiment 1, specifically:

[0082] The conductive PVC material comprises the following components by weight percentage:

[0083] PVC 60

[0084] Carbon Black 15

[0085] Conductive polyaniline 15

[0086] Polyethylene wax 2

[0087] Triphenyl phosphate 7

[0089] Among them, the particle size of carbon black is 0.2 μm

[0090] The preparation method of described conductive PVC material is:

[0091] 1) Put PVC and polyethylene wax into the mixing machine and knead, and when the PVC is in a viscous state, add other components to knead together;

[0092] 2) Send the material in the previous step into the extrusion granulator, and extrude to obtain PVC pellets;

[0093] Next, the PVC pellets are sent into the injection molding machine for injection molding to form the connecting pipe.

[0094] Between two adjacent straight pipes, and between the straight pipes...

Embodiment 3

[0104] combine Figure 7 , Figure 8 , as shown, this embodiment makes further limitations and descriptions on the basis of embodiment 1 or 2, specifically:

[0105] The straight pipe is formed by cutting a continuous pipe. When the pipe is extruded, a socket mouth is formed at a set distance, and the socket mouth is cut at the middle position by a cutting machine to form the described The socket, the pipe is cut at the part between two adjacent sockets to form two sections of the straight pipe.

[0106] The equipment for molding said pipes includes an extruder 61, a head die 62, a vertical forming device 63, a vacuum setting spray box 64, a tractor 65, a cutting machine 66 and a stacking pipe rack 67 arranged in sequence; The head and die are connected to the discharge end of the extruder.

[0107] The outer end of the mandrel of the nose die is connected with a connecting rod 621, and the other end of the connecting rod is connected with two stoppers 622, and the distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap