Gas pressure sensor device based on conduction properties of graphene

A pressure sensor, graphene film technology, applied in elastic deformation meter type fluid pressure measurement, fluid pressure measurement by changing ohmic resistance, etc., can solve the problem of difficult gas pressure measurement, etc. super powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

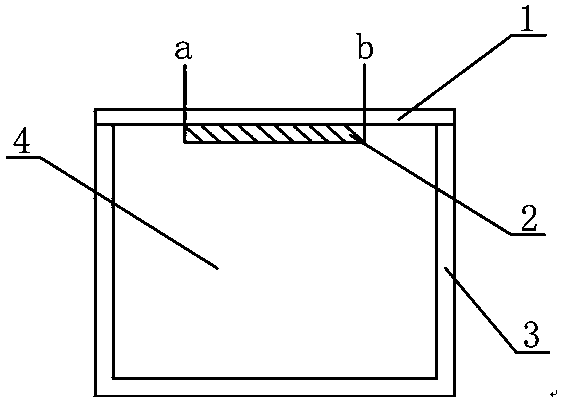

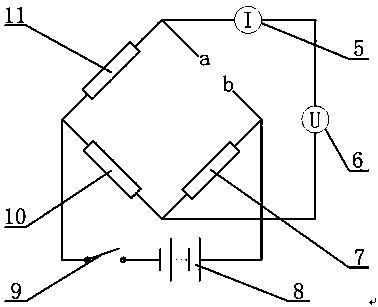

Method used

Image

Examples

example 1

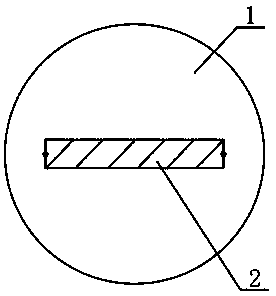

[0021] Example 1: The length of the graphene film is 1 mm, the width is 500 μm, and the thickness is 0.35 nm. The radius of the circular single crystal silicon plate is 2 mm. The Poisson’s ratio of the circular single crystal silicon plate is 0.35. The circular single crystal silicon plate The modulus of elasticity is 190GPa, and the external power supply is 2V.

[0022] When the circular monocrystalline silicon plate is bent, the graphene film is driven to bend. The reading value of the voltmeter is 920mV, and the calculated pressure difference is 13280Pa. Knowing that the outside of the container is atmospheric pressure, the internal pressure of the container is 88045Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com