Light beam phase modulation and direction adjustment device

A phase modulation and direction modulation technology, applied in optics, optical components, instruments, etc., can solve the problems of low precision, complex optical synthetic aperture common phase method, etc., and achieve low cost, important technical value and economic value, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

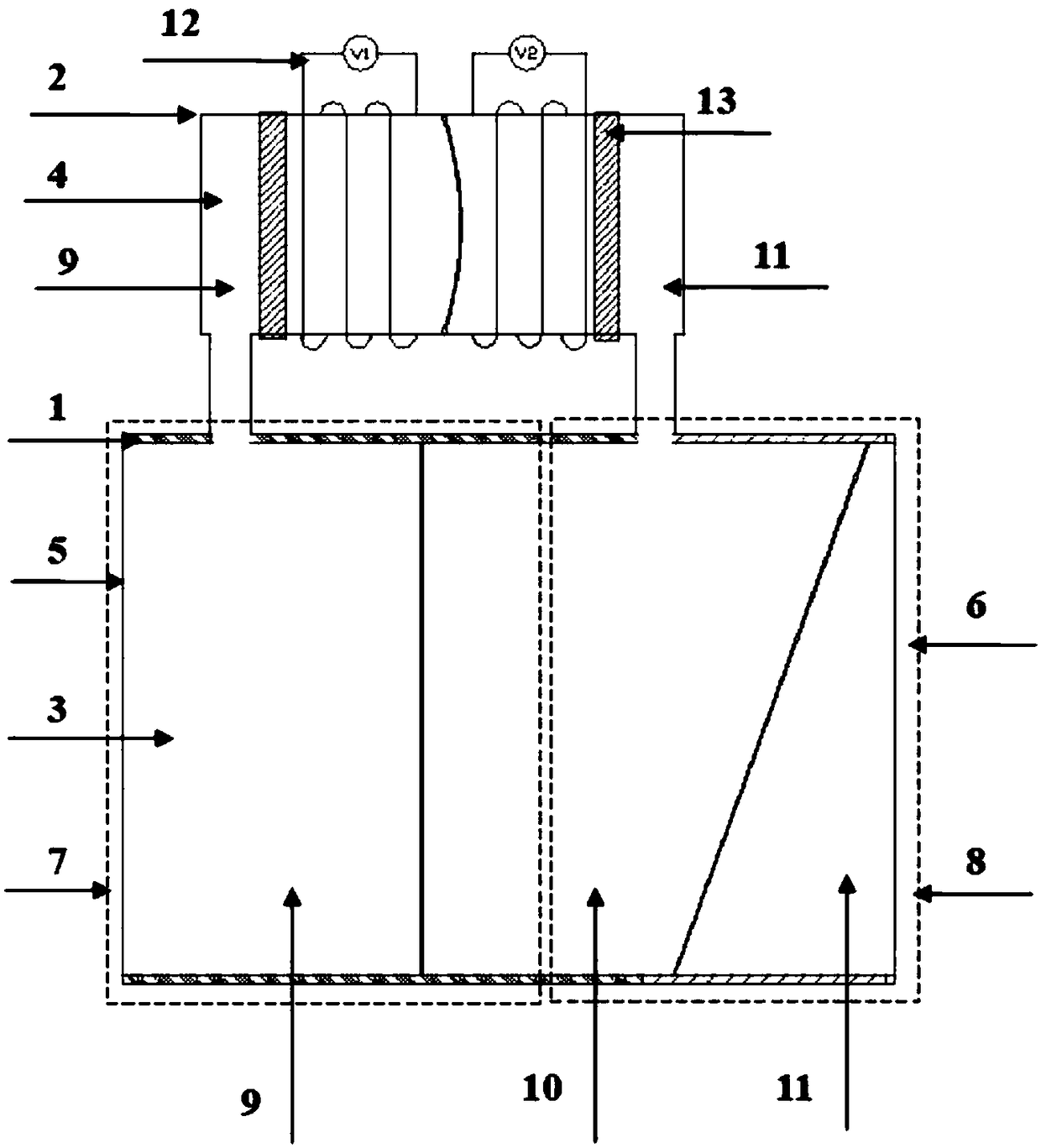

Embodiment 1

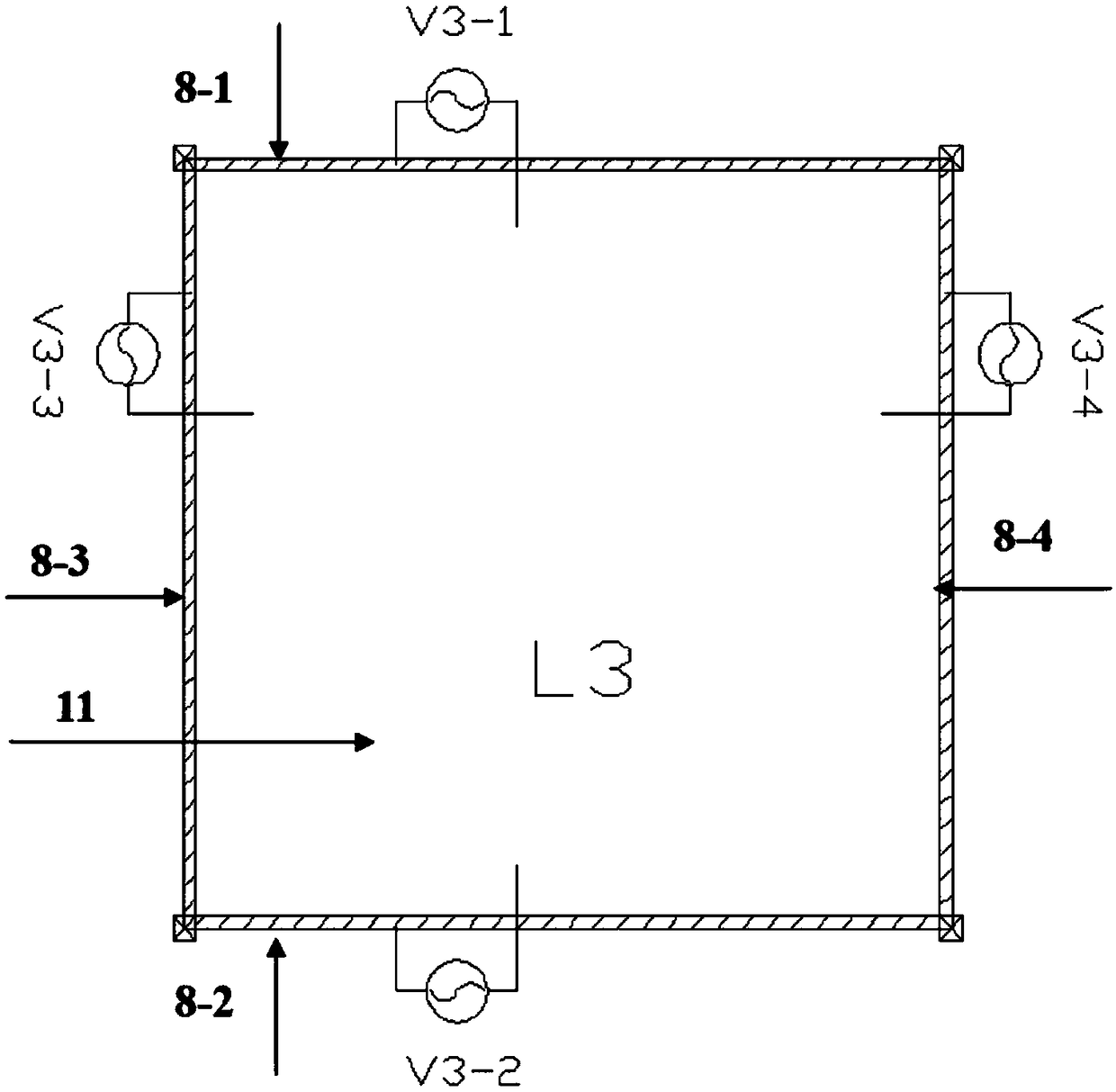

[0029] The phase-modulating cavity is made of metal round tube, and the inner wall is coated with Teflon film; the inner chip where the direction-tuning cavity is located uses the same metal tube as the above-mentioned phase-modulating cavity, which is cut into 4 parts on average along the axial direction and leads out electrodes , and then use epoxy resin to bond them together, coat the inner wall with evaporated 3-10μm Parylene insulating dielectric material, and then coat a very thin layer of Teflon@1600, and set the voltage V3-1~V3- 4 Applied to the above four electrodes respectively; use a soft plastic round tube to make the driving inner core and package it, open a hole in the left part of the first liquid in the phase-modulating chamber, open a hole at the left end of the driving inner core, and use a thin tube to connect the two holes To connect, open a hole near the middle of the second liquid in the phase adjustment chamber, open a hole at the right end of the driving...

Embodiment 2

[0034] The phase adjustment cavity is made of plastic hard round tube, which is convenient for industrial scale production. Because the plastic itself has hydrophobic properties, a layer of grease is coated on its inner wall; the inner chip where the adjustment cavity is located is made of the same plastic as the above phase adjustment cavity. The hard round tube is evenly plated with 4 pieces of tile-shaped metal nickel on its inner wall and leads to 4 electrodes, and the inner wall is coated with 3-10μm parylene insulating dielectric material, and then coated with a very thin layer Teflon@1600, and set the voltage V 3-1 ~V 3-4Applied to the above four electrodes respectively; use PDMS to make the driving inner core and package it, open a hole in the left part of the first liquid in the phase modulation chamber, open a hole at the left end of the driving inner core, and use a thin tube to connect the two holes, A hole is opened near the middle of the second liquid in the pha...

Embodiment 3

[0039] The phase-modulating cavity is made of hardened silicone rubber round tube, which is convenient for industrial scale production. Since the silicone rubber itself has hydrophobic properties, a layer of grease is coated on its inner wall; The same hardened silicone rubber round tube is evenly plated with 4 tile-shaped silicone rubber made of conductive silicone rubber on its inner wall and leads to 4 electrodes, then bonded with PDMS, and then evaporated on its inner wall 1-10μm PDMS insulating dielectric material, then coated with a very thin layer of Teflon@1600, and set the voltage V 3-1 ~V 3-4 Applied to the above four electrodes respectively; use PDMS to make the driving inner core and package it, open a hole in the left part of the first liquid in the phase modulation chamber, open a hole at the left end of the driving inner core, and use a thin tube to connect the two holes, Open a hole near the middle of the second liquid in the phase adjustment chamber, drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com