Industrial SCADA (Supervisory Control and Data Acquisition) system simulation platform

A system simulation and industrial technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problem of no simulation platform for industrial control systems, and achieve the effect of easy updating and expansion, convenient deployment, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

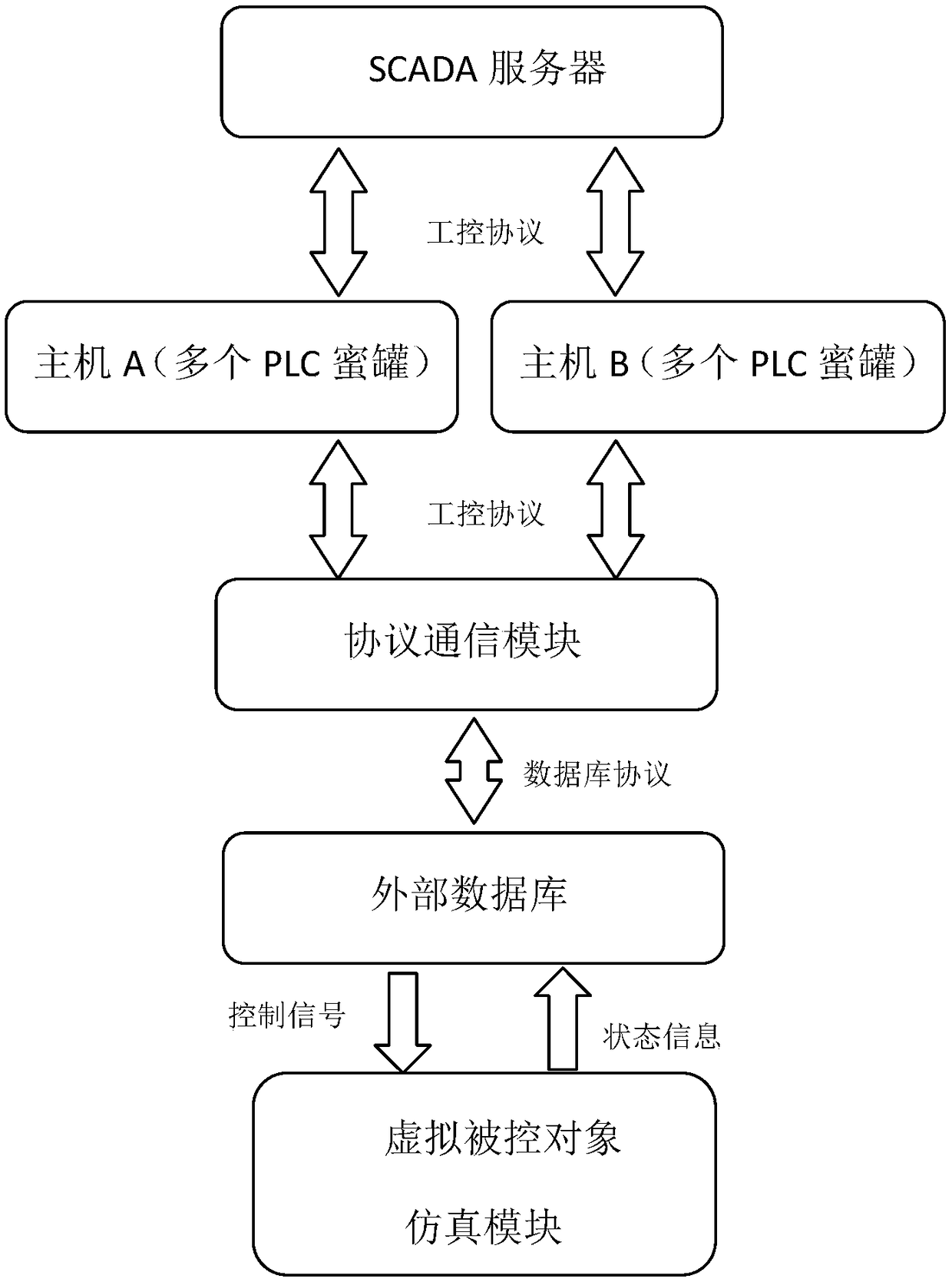

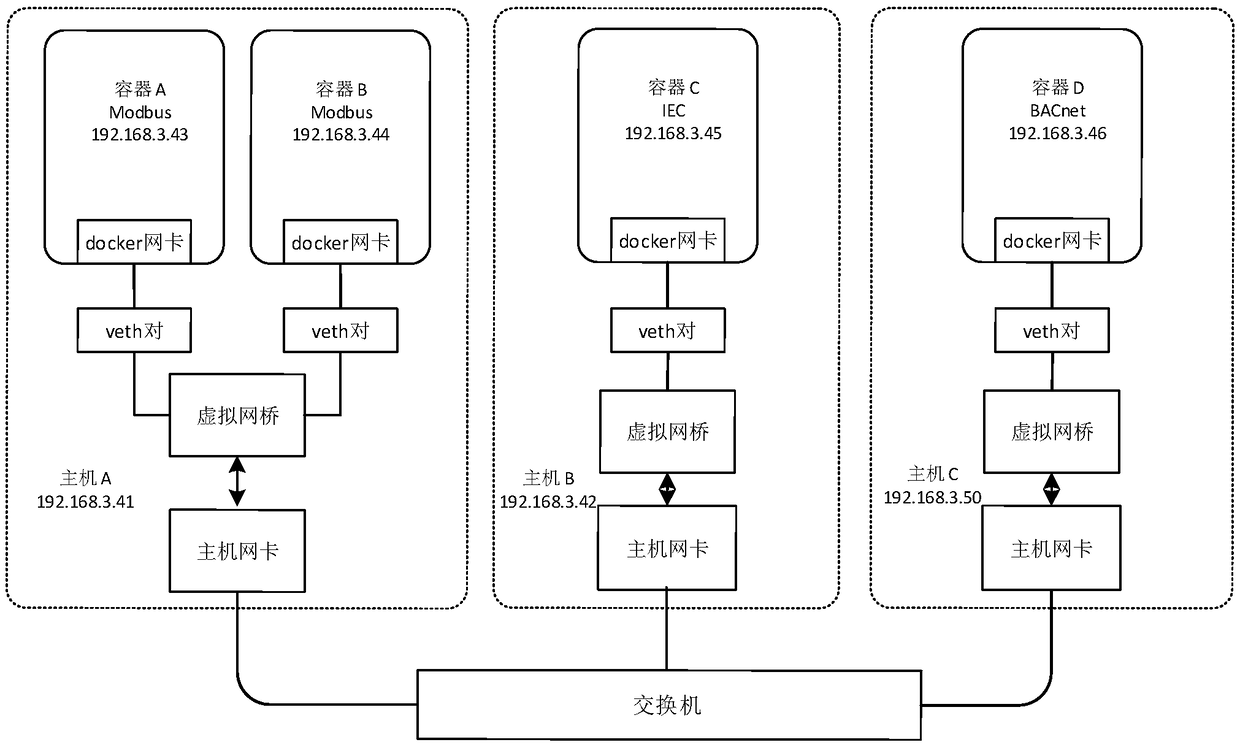

[0042] The implementation protocol of the industrial SCADA system simulation platform provided by the invention includes protocols such as Modbus / TCP, IEC 60870-5-104, and BACnet / IP. The platform consists of four parts: a simulation module for simulating a virtual controlled object, a PLC (programmable logic controller) honeypot, a SCADA server (PLC upper computer), and a protocol communication module. The platform specifically simulates the network data flow of industrial SCADA systems including a variety of typical industrial control protocols, and adopts the simulation construction method based on docker and PLC honeypot to coordinate the authenticity and scalability of the platform, and realize the simulation in the real industrial control system environment It has the characteristics of large scale nodes, multiple protocols, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com