A processing method using indica rice as a raw material for making rice dumplings and sushi with low GI value

A processing method and technology of raw materials, applied in the direction of food ultrasonic treatment, food ingredients as taste improvers, applications, etc., can solve the problem of hard taste but not sticky, and achieve the effect of soft taste, lower price and higher viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

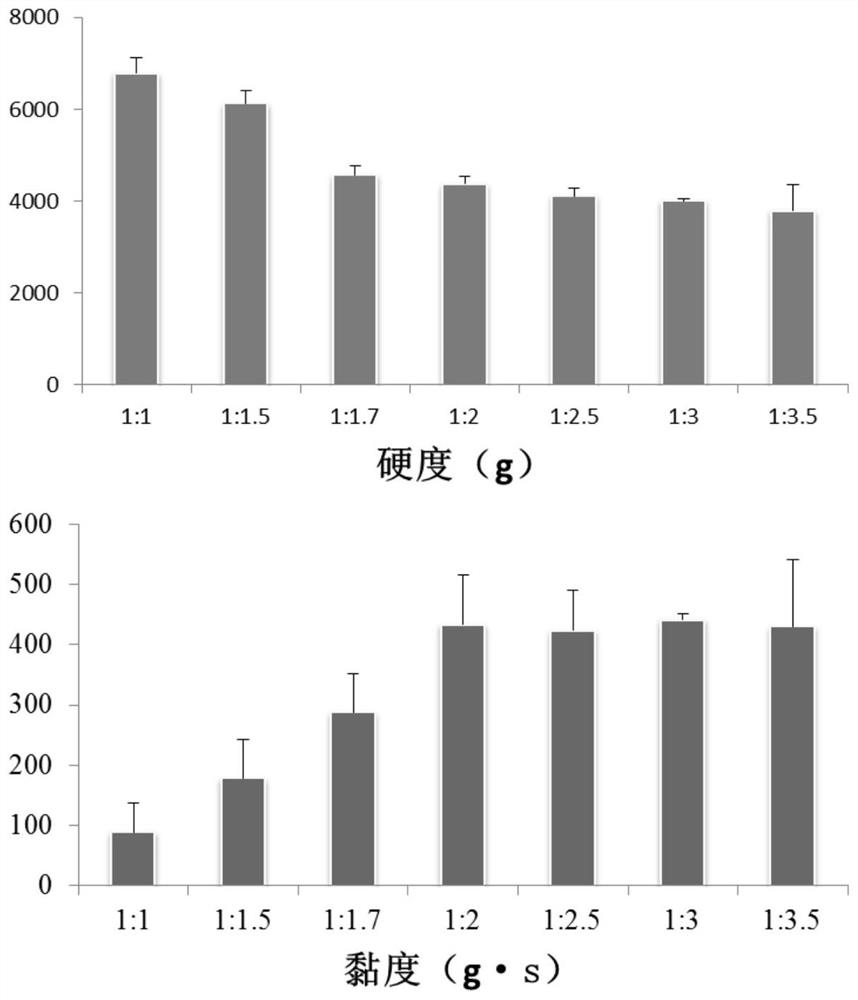

[0033] 1) Mix indica rice in water (mass ratio of indica rice to water: 1:2), soak for 1 hour, put the mixture of indica rice and water in an ultrasonic treatment tank, turn on the ultrasonic equipment, and perform ultrasonic treatment on indica rice. Soaking water was decanted to obtain ultrasonically treated indica rice; ultrasonic conditions were: ultrasonic power 400W, frequency 40KHz, temperature 40°C, work / intermittent ratio 3s / s, ultrasonic time 30min.

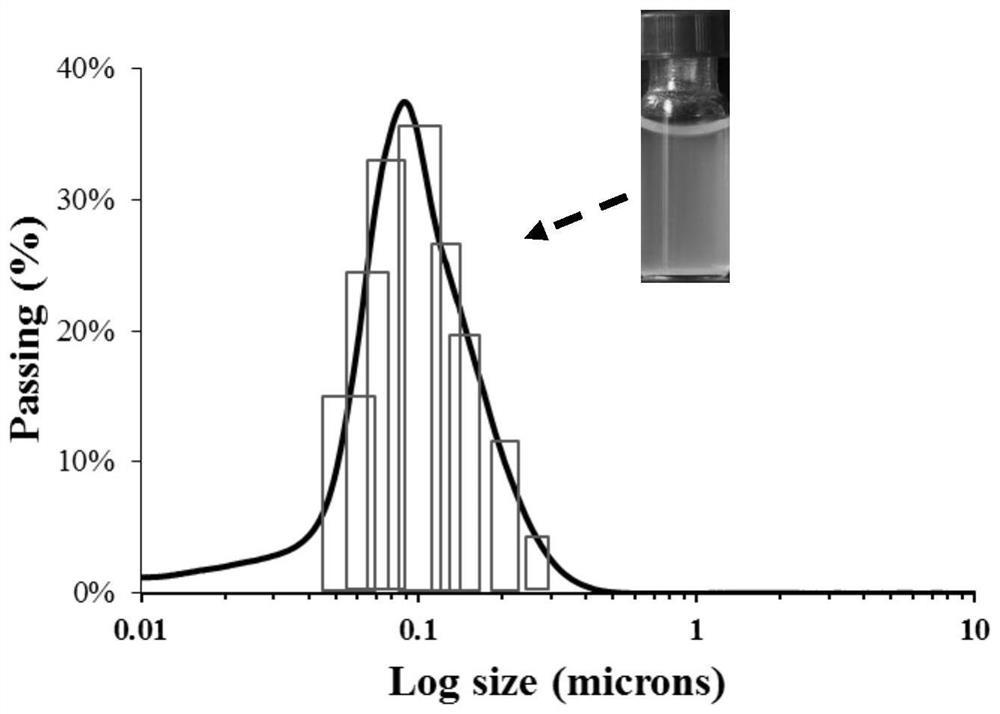

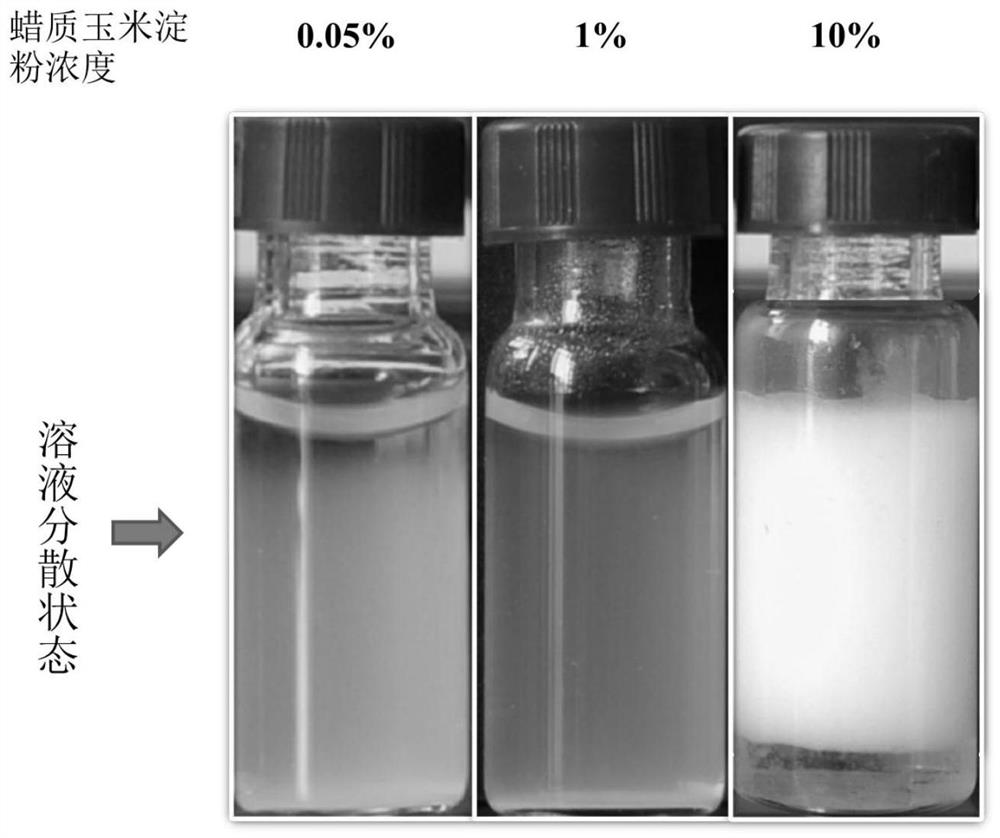

[0034] 2) Prepare 1% waxy cornstarch slurry, inject the cornstarch slurry into a micro-fluidic homogenizer, and circulate it 18 times at a flow rate of 130ml / min at 200MPa and 3°C to prepare nanoscale waxy cornstarch colloid .

[0035] 3) Mix the ultrasonically treated indica rice and nano-grade starch colloid in a weight ratio of 1:2, pour it into a container, soak it at 45°C for 30mins, let it fully absorb the water, and stir it 8 times during the period to obtain the low Indica rice which is the raw material of rice...

Embodiment 2

[0037] 1) Mix indica rice in water (mass ratio of indica rice to water: 1:1.5), soak for 1 hour, put the mixture of indica rice and water in an ultrasonic treatment tank, turn on the ultrasonic equipment, and perform ultrasonic treatment on indica rice. Soaking water was decanted to obtain indica rice after ultrasonic treatment; the ultrasonic conditions were: ultrasonic power 1000W, frequency 20KHz, temperature 25°C, work / intermittent ratio 1s / s, ultrasonic time 5min.

[0038] 2) Prepare 5% waxy wheat starch slurry, inject the corn starch slurry into a micro-fluidic homogenizer, and circulate 18 times at a flow rate of 80ml / min at 150MPa and 5°C to prepare nanoscale waxy wheat starch colloid .

[0039] 3) Mix the ultrasonically treated indica rice and nano-grade starch colloid in a weight ratio of 1:2, pour it into a container, soak it at 55°C for 15 minutes, let it fully absorb water, and stir it 3 times during the period to obtain the low Indica rice which is the raw mater...

Embodiment 3

[0041] 1) Put indica rice into water and mix (mass ratio of indica rice to water: 1:1.5), after soaking for 2 hours, put the mixture of indica rice and water in an ultrasonic treatment tank, turn on the ultrasonic equipment, and carry out ultrasonic treatment on indica rice. Soaking water was decanted to obtain ultrasonically treated indica rice; ultrasonic conditions were: ultrasonic power 500W, frequency 30KHz, temperature 30°C, work / intermittent ratio 2s / s, ultrasonic time 15min.

[0042] 2) Prepare 3% waxy cornstarch slurry, inject the cornstarch slurry into a micro-jet homogenizer, and circulate it 18 times at a flow rate of 100ml / min at 150MPa and 5°C to prepare nanoscale waxy cornstarch colloid .

[0043] 3) Mix the ultrasonically treated indica rice and nano-grade starch colloid according to the weight ratio of 1:1.7, pour it into a container, soak it at 55°C for 15 minutes, let it fully absorb water, and stir it 5 times during the period to obtain the low Indica rice w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com