Multifunctional pneumatic microfluid control system, intermittent sample injection system and control method

A control system and microfluidic technology, applied in the field of microfluidics, can solve the problems of complicated operation, continuous sampling time limitation, etc., and achieve the effect of preventing cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

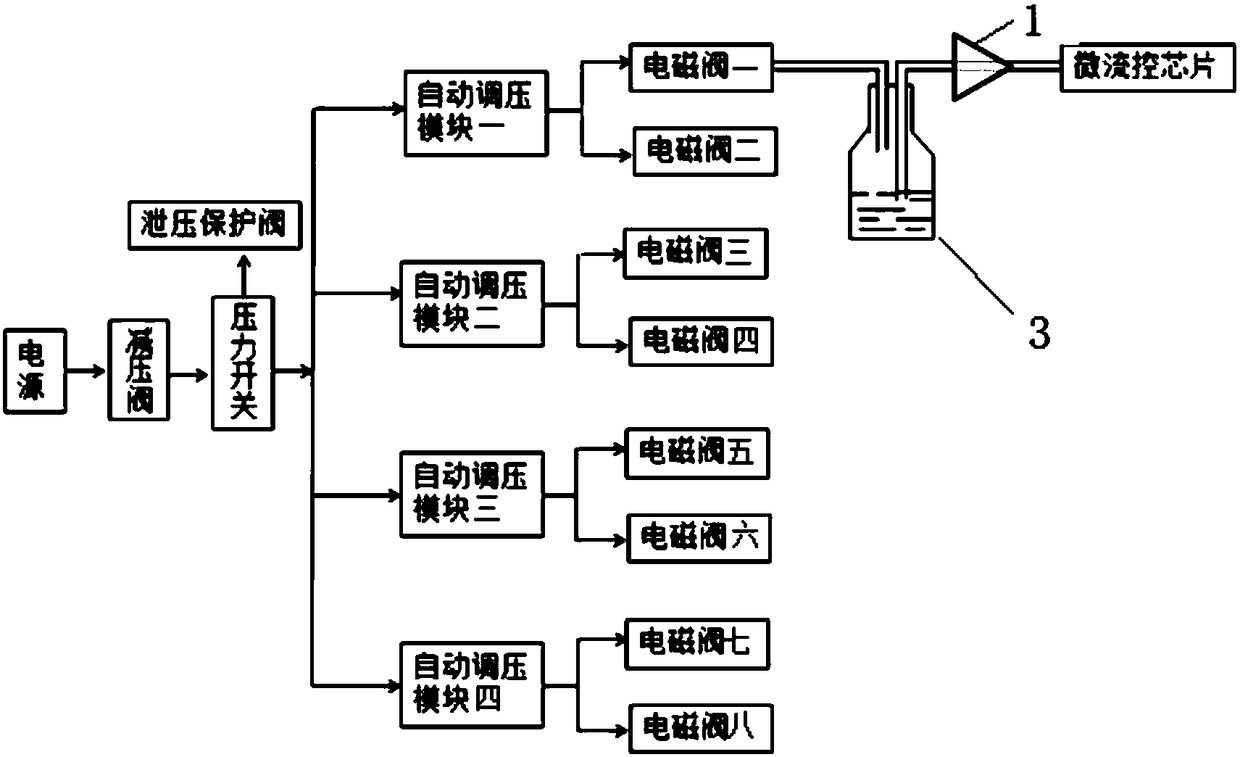

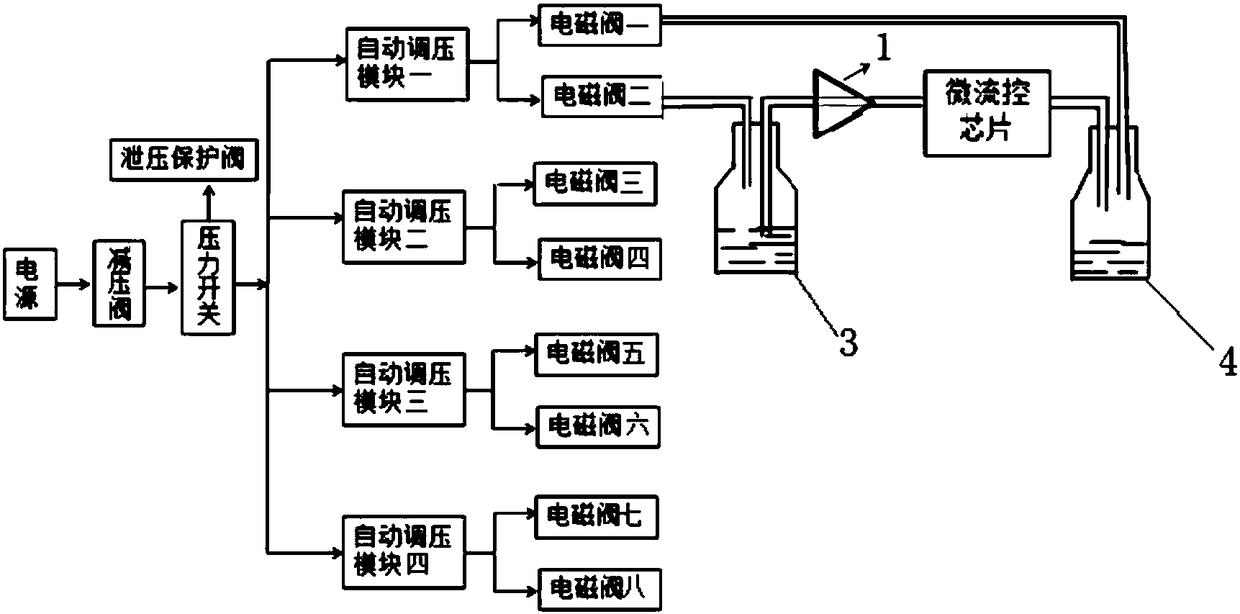

[0071] The first control method is as figure 2 As shown, the pneumatic microfluidic control system capable of intermittent sample injection adopts the described multifunctional pneumatic microfluidic control system, the microfluidic chip is connected to the air inlet of the second liquid container 4 through a pipeline, and the second liquid The liquid outlet pipe of the container is connected to another solenoid valve on the branch connected with the outlet pipe of the corresponding automatic pressure regulating module.

[0072] The control method of the control system includes:

[0073] The parameters set through the control panel include the opening of each automatic pressure regulation module, the stop of each automatic pressure regulation module, the pressure value of each automatic pressure regulation module, the opening of each solenoid valve, the stop of each solenoid valve and the setting of each solenoid valve. start time and stop time;

[0074] Regulate the pressu...

Embodiment 2

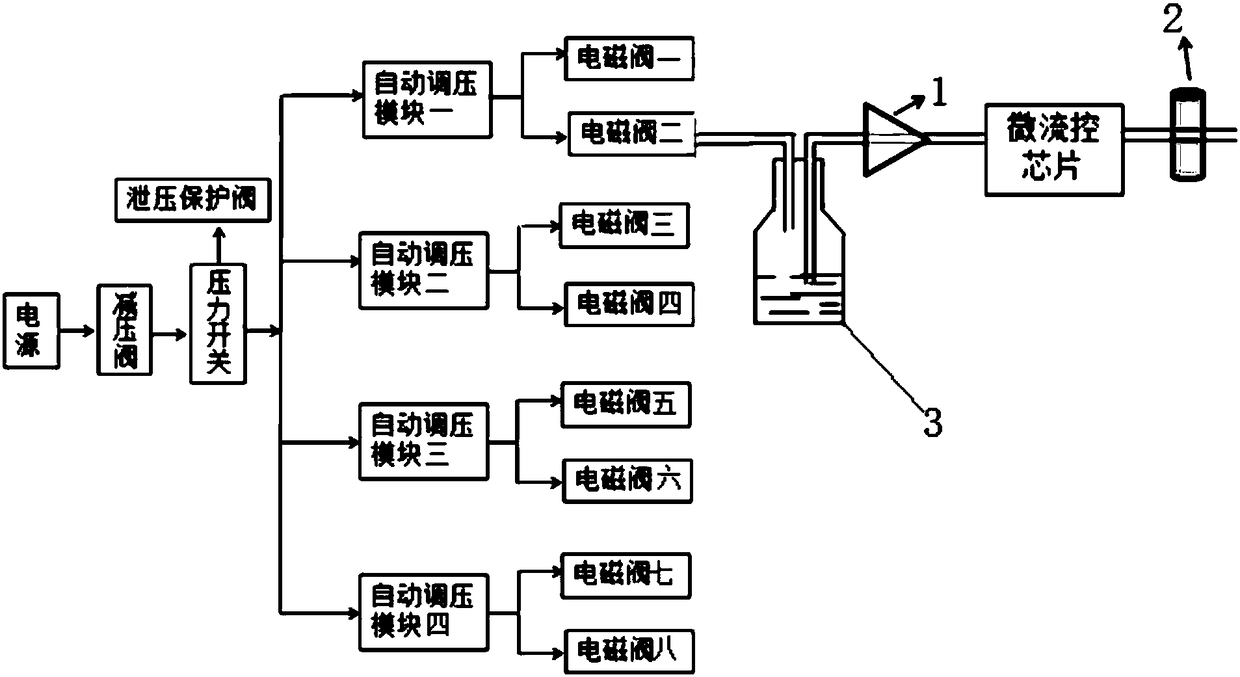

[0082] The second control method is as image 3 As shown, the pneumatic microfluidic control system capable of intermittent sampling adopts the multifunctional pneumatic microfluidic control system described above, and a pinch valve 2 is provided on the output pipeline of the microfluidic chip.

[0083] The control method of the control system includes:

[0084] The parameters set through the control panel include the opening of each automatic pressure regulation module, the stop of each automatic pressure regulation module, the pressure value of each automatic pressure regulation module, the opening of each solenoid valve, the stop of each solenoid valve and the setting of each solenoid valve. start time and stop time;

[0085] Regulate the pressure of the whole system through the pressure reducing valve;

[0086] The pressure value of the control system is displayed through the pressure switch, and the upper and lower limits of pressure can be set through the pressure swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com