An integrated assembly system and assembly method for microwave device components

A microwave device and assembly system technology, which is applied in the direction of instruments, computer parts, and collaborative devices, etc., can solve the problems that it is difficult to follow the rapid assembly speed and circulation speed of components, affect the assembly efficiency of component assembly equipment, and scrap semi-finished components. Achieve the effects of avoiding assembly position deviation, preventing wrong assembly, and reducing operator fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

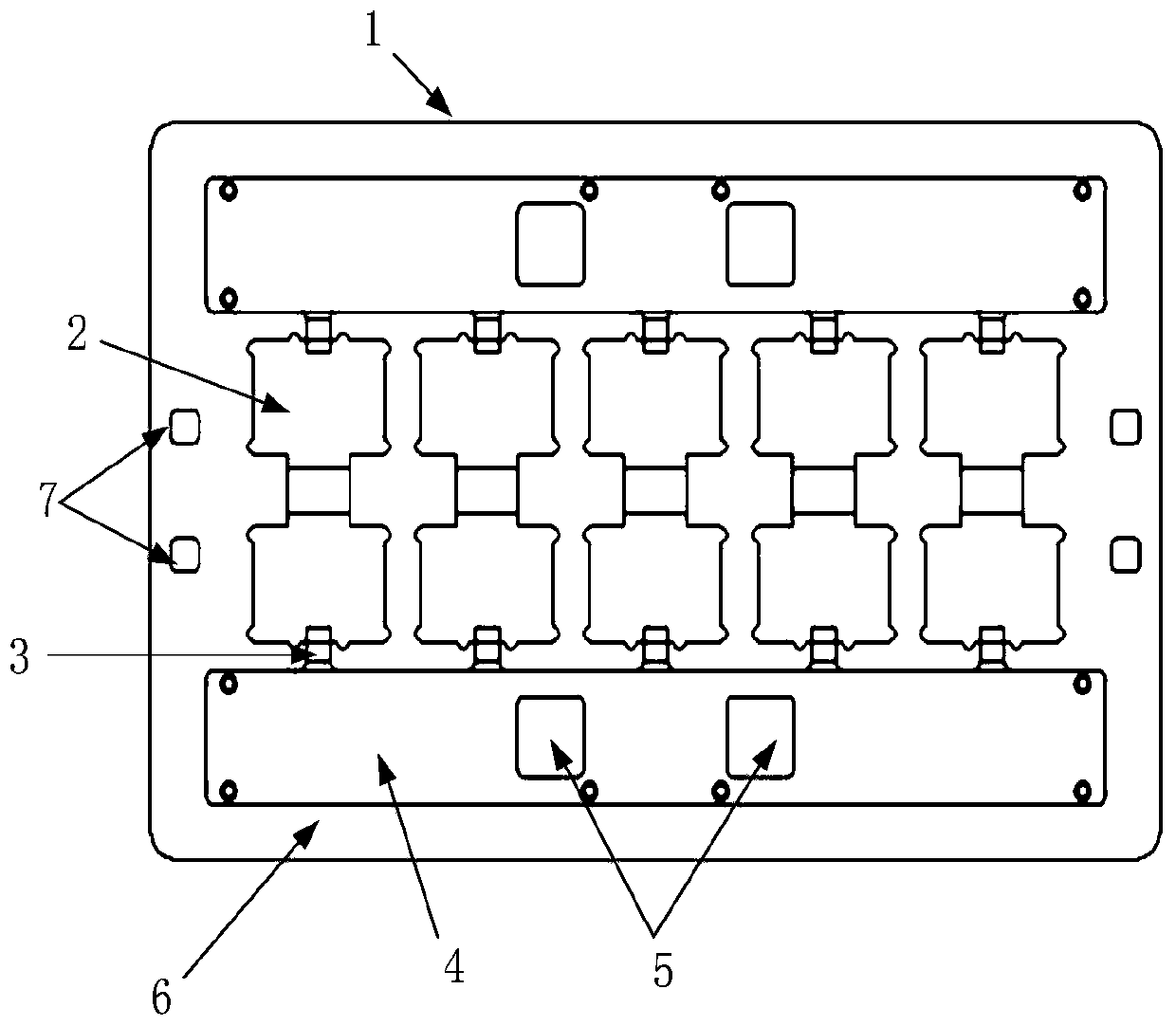

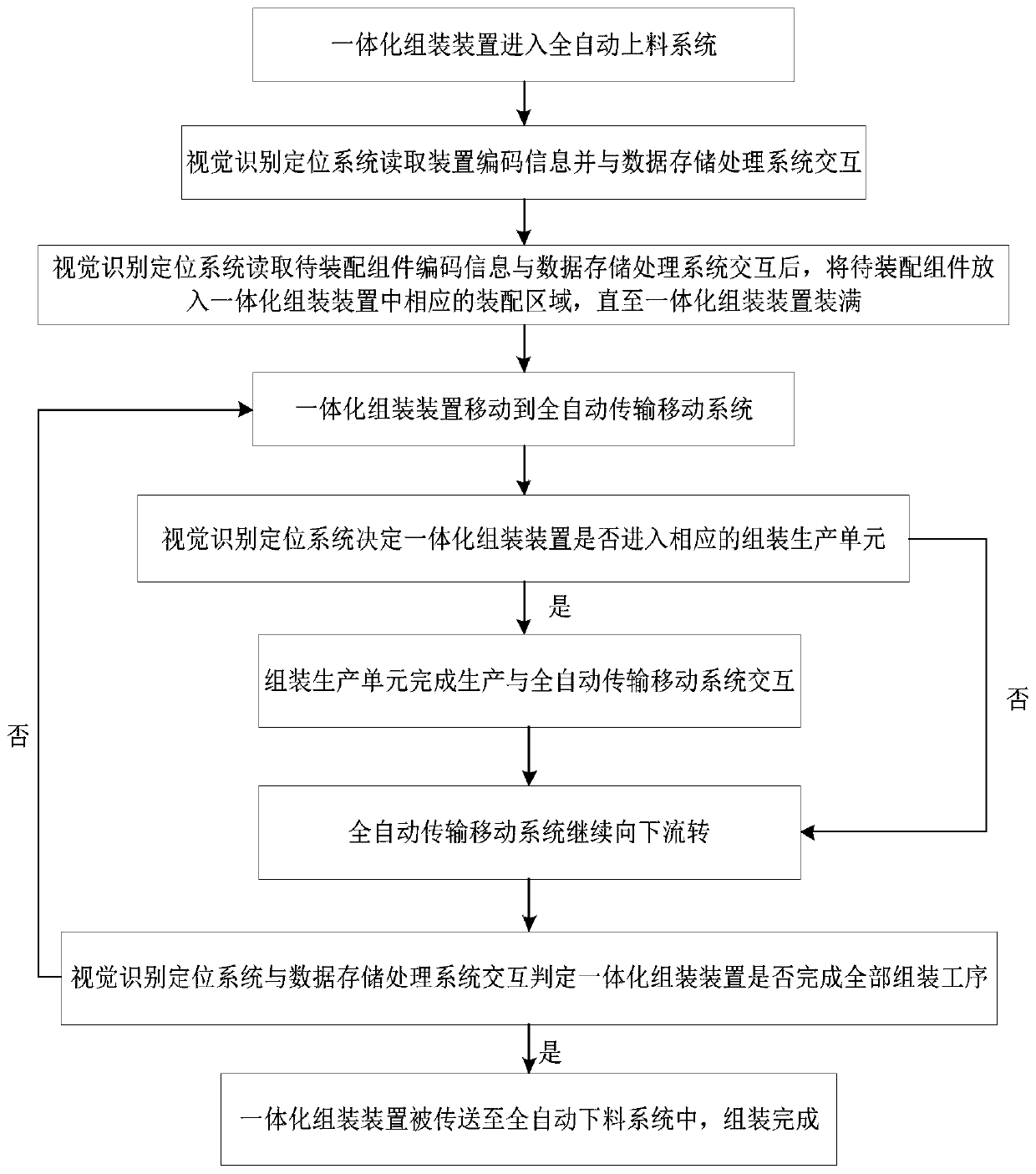

[0041] The integrated assembly system for microwave device components in this embodiment includes an integrated assembly device, a fully automatic loading system, multiple assembly production units, a fully automatic transmission and movement system, a fully automatic unloading system, and a data storage and processing system. The automatic feeding system, multiple assembly production units and the fully automatic unloading system are connected through a fully automatic transmission mobile system, and the integrated assembly device is connected between the fully automatic feeding system, multiple assembly production units and the automatic transmission mobile system through the automatic transmission mobile system. The data storage and processing system is connected to the fully automatic transmission mobile system, the fully automatic loading system and multiple assembly production units at the same time, and is used for data interaction with each system, and the read informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com