Steel wire cutter body laser heat treatment technological parameter optimization method

A technology of process parameter optimization and steel wire knife, which is applied in the application field of artificial neural network and genetic algorithm, can solve the problems of difficult processing model and achieve the effect of optimal laser heat treatment process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

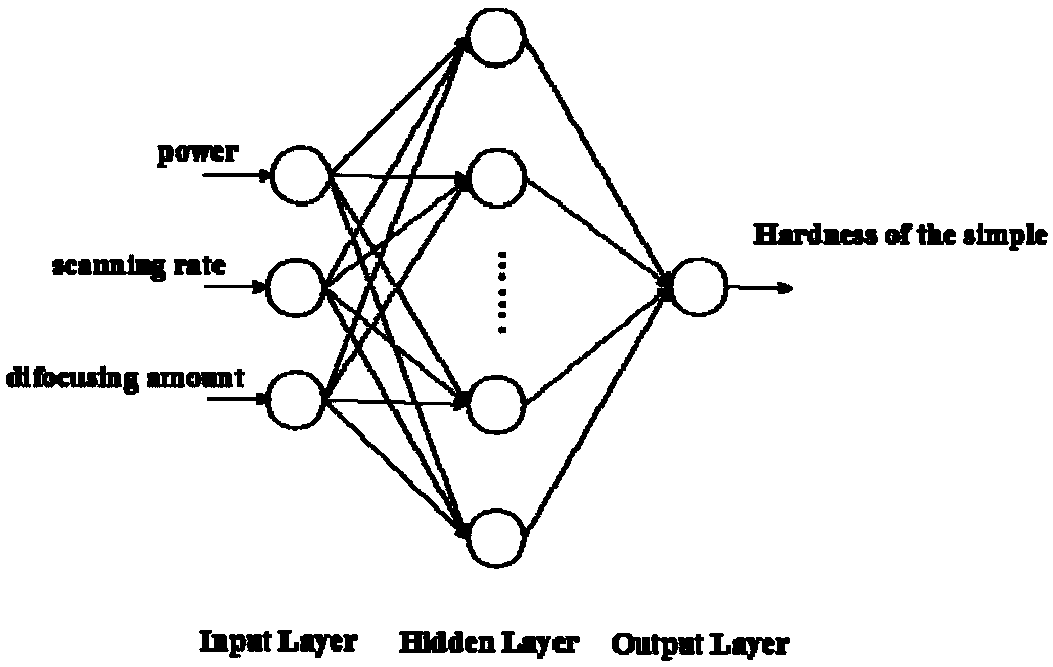

Method used

Image

Examples

Embodiment

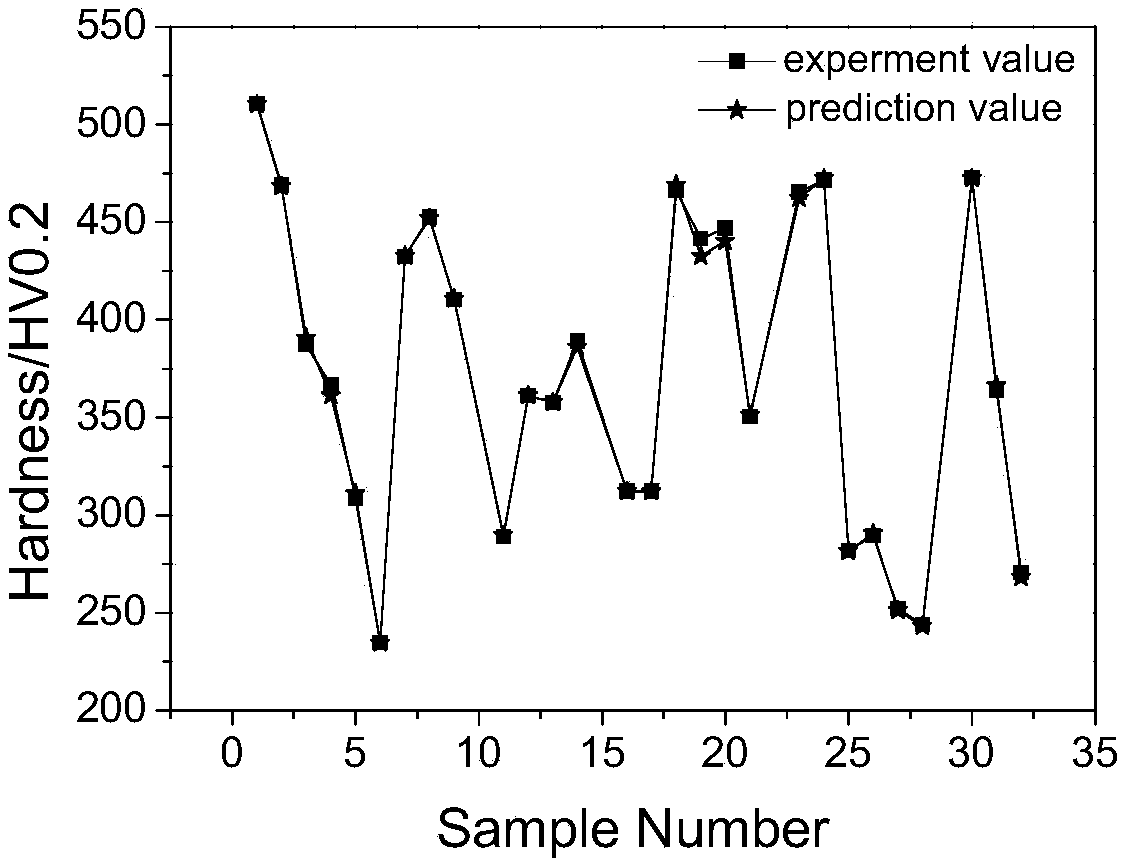

[0047] For better reflecting the effect of the present invention, now the present invention method is carried out actual operation, adopts the method of experiment to record 32 samples in this example, and concrete data is as table 2, wherein 28 are randomly selected for training artificial neural meta-network, and the remaining samples are used to test the performance of the trained artificial neuron network.

[0048] Table 2 Hardness test results of steel wire knife under different laser processing parameters

[0049]

[0050]

[0051] *For test sample

[0052] The MSE measured on the artificial neural network training data is 6.0858×10 -5 , achieved an MSE of 10 -4 The target, the MSE obtained from the test data is 9.5×10 -5 , also up to 10 -4 The goal. This shows that the obtained artificial neural network can predict the microhardness of the steel wire knife blade more accurately.

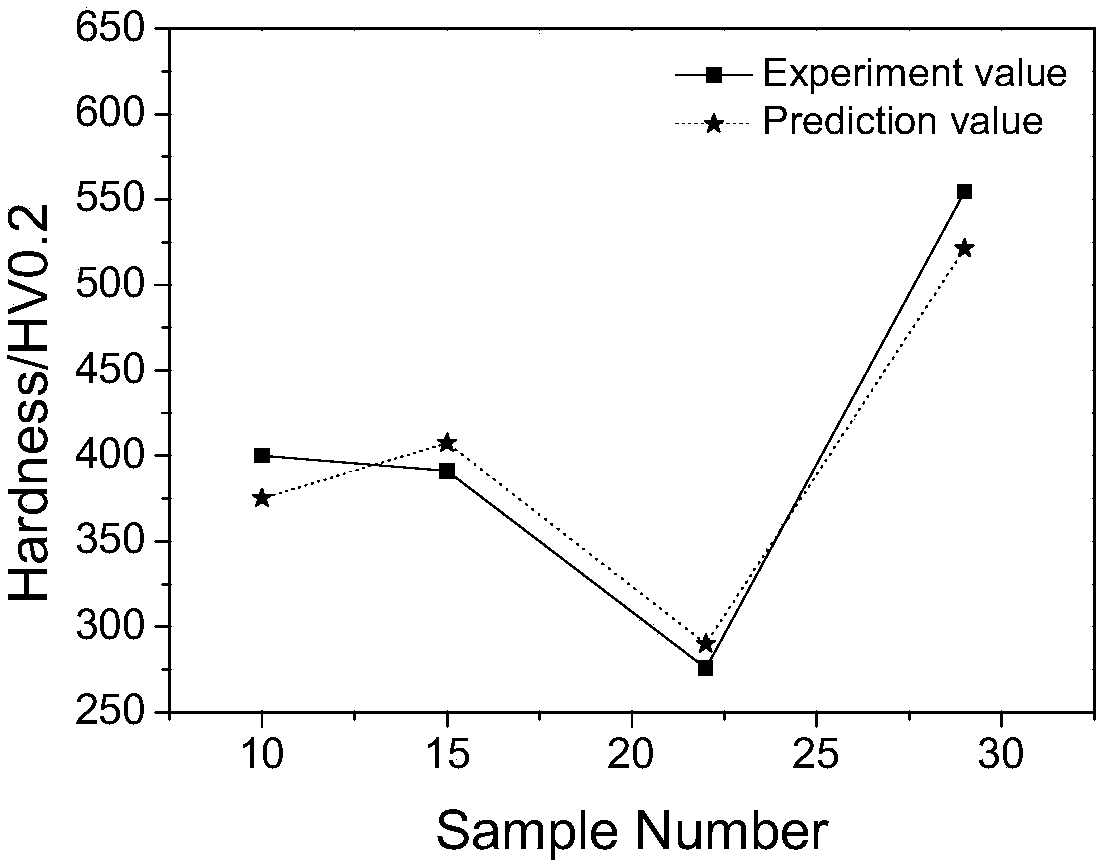

[0053] The genetic algorithm is used to find the optimal parameters, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com