Automatic wall-brushing machine

An automatic brushing and wall machine technology, which is applied in the direction of mixers, driven agitator dissolvers, mixers with rotating stirring devices, etc., can solve the problems of low wall brushing efficiency and uneven thickness of spray paint coating, and improve the painting effect , good practicability and scalability, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

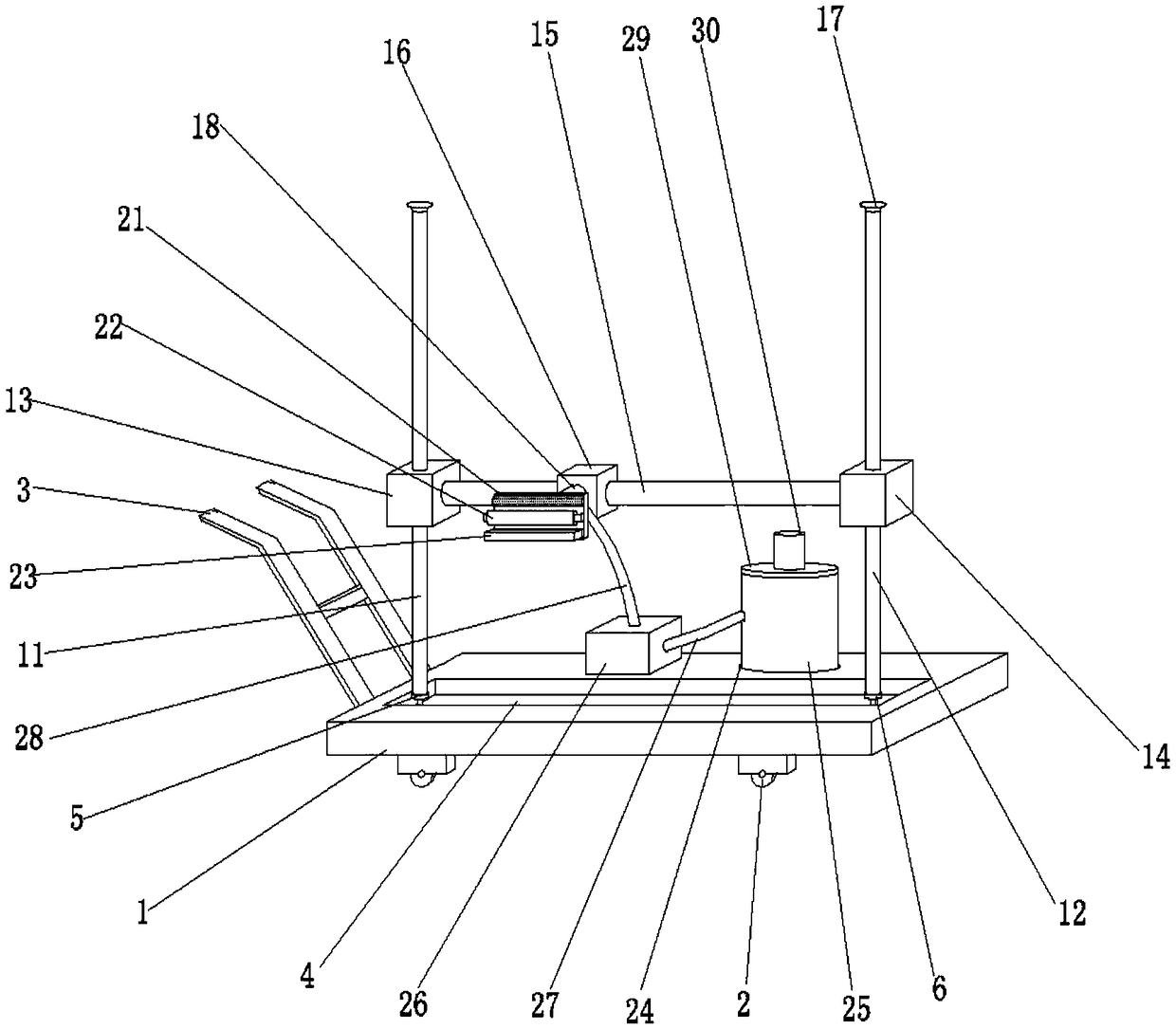

[0020] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

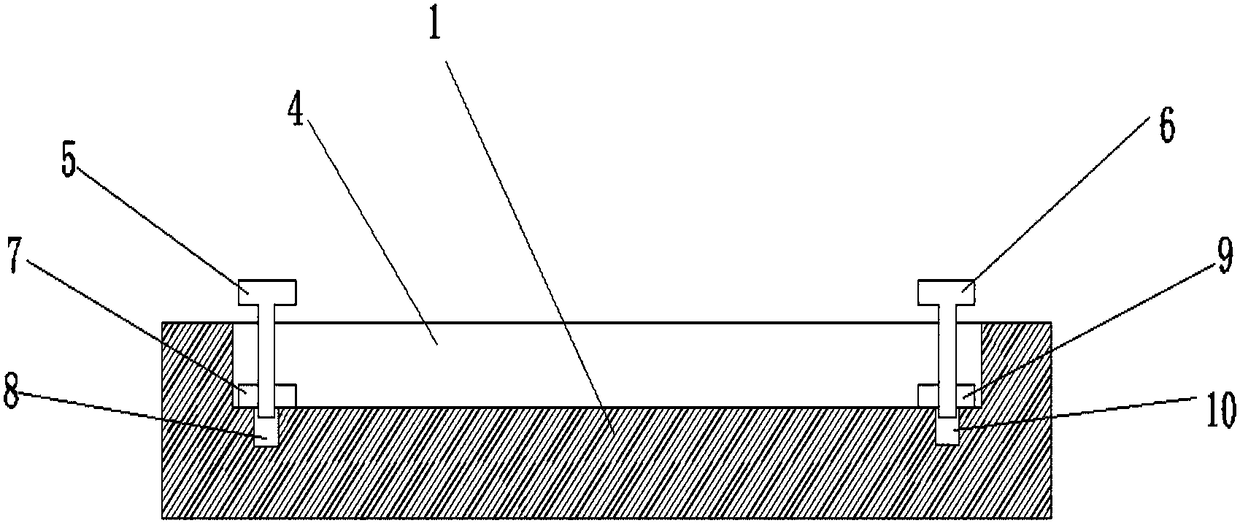

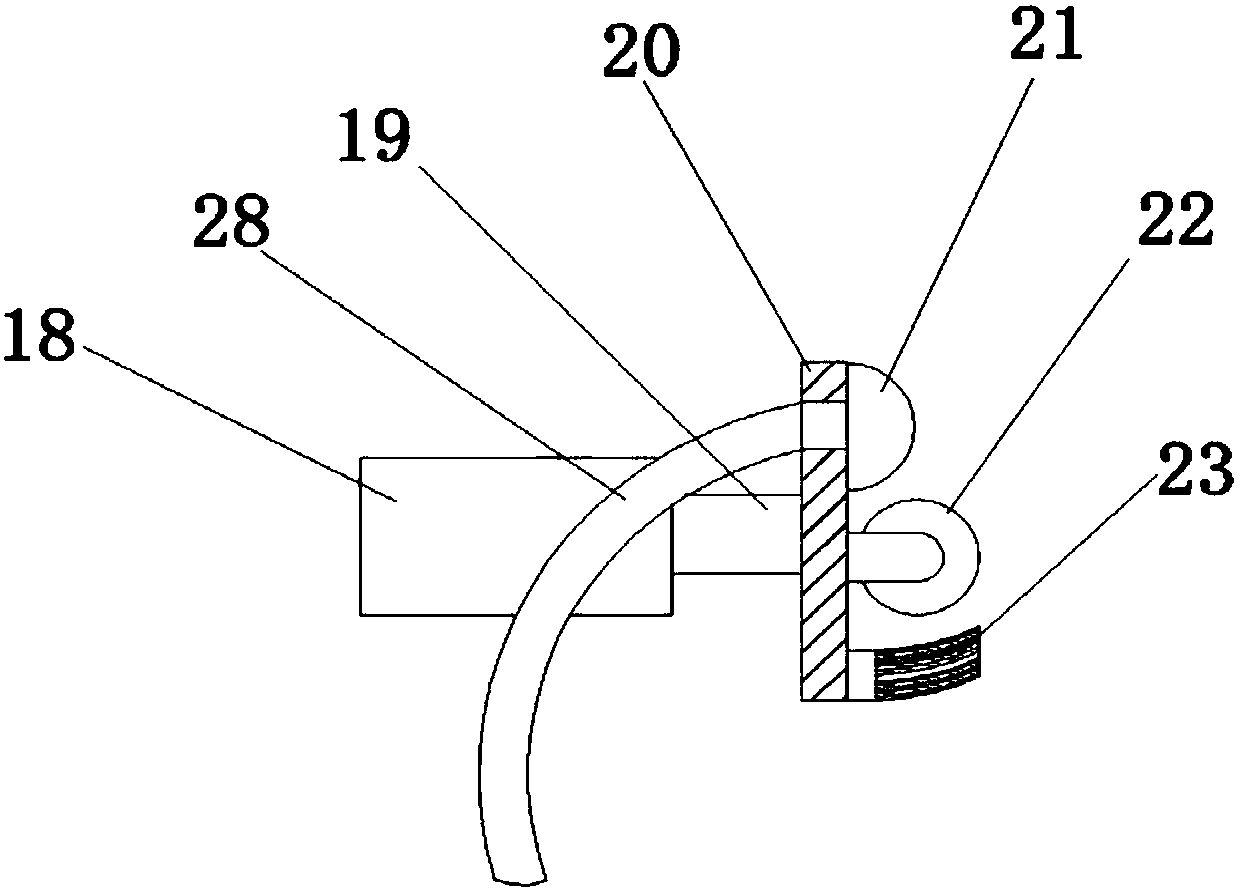

[0021] combine Figure 1 to Figure 5 , an automatic wall brushing machine, comprising a car body 1, the bottom of the car body 1 is provided with a roller 2, one end of the car body 1 is provided with a hand push 3, and the upper surface of the car body 1 is provided with a first groove 4 and a second Groove 24, the first groove 4 is positioned at the side of car body 1, and first groove 4 is rectangular structure, and the length of first groove 4 does not exceed the length of car body 1, and the bottom both sides of first groove 4 Symmetrically provided with a first level adjustment base and a second level adjustment base, the first level adjustment base includes a first adjustment screw 5 and a first fixing nut 7, the first fixing nut 7 is fixed on the bottom of the first groove 4, the second An adjusting screw rod 5 is screwed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com