Counterweight type loop control system and method

A control system and looper technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as many operating errors, affecting product quality, and system complexity, optimizing system operating parameters and facilitating system maintenance. Flexible, simple and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

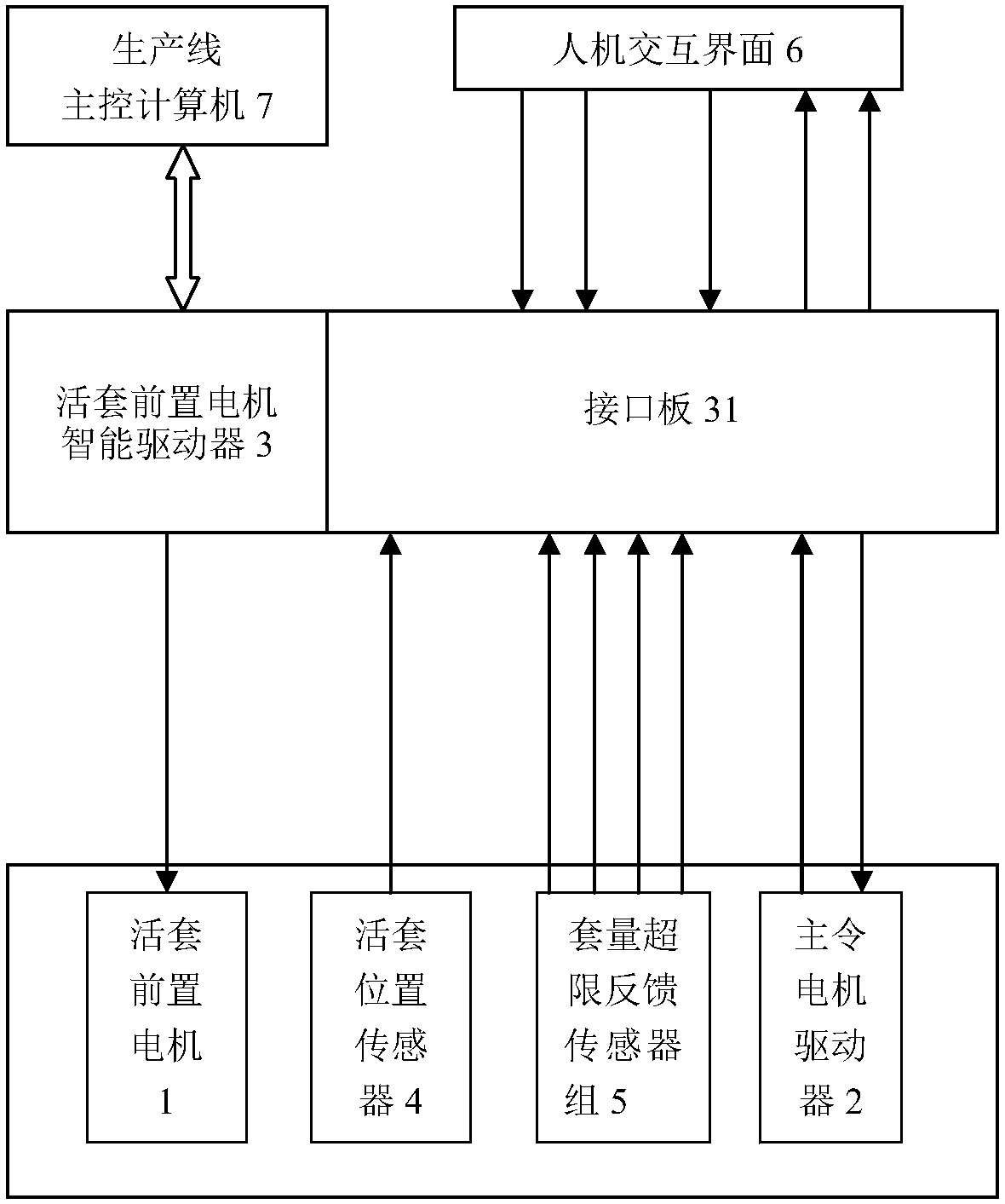

[0027] See figure 1 , The counterweight type looper control system of this embodiment is described by taking the counterweight type looper control system used for the transmission control of the continuous processing production line of coils and strips as an example. It consists of a set motor 1, a master motor driver 2, a looper front motor intelligent driver 3, a looper position sensor 4, a set of overrun sensors 5 and a human-machine interface 6.

[0028] The looper front motor 1 is used to perform the operation of filling and discharging the counterweight type looper on the production line, and the looper front motor 1 is provided with a drive control signal input end;

[0029] The master motor driver 2 is used to drive the master motor that drives the production line. The master motor driver 2 is provided with a master motor speed feedback output terminal and a master motor stop signal input terminal;

[0030] The looper front motor intelligent driver 3 is used to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com