Capacitive-resistant load high-current impact type direct-current relay

A DC relay and current impact technology, which is applied in the direction of electromagnetic relay, electromagnetic relay details, relay, etc., can solve the problems of relay contact separation failure, high overall cost, and out-of-control power supply cut-off, so as to improve the stability and reliability of use and use Long life, reduce the damage caused by the circuit, and avoid the effect of high current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

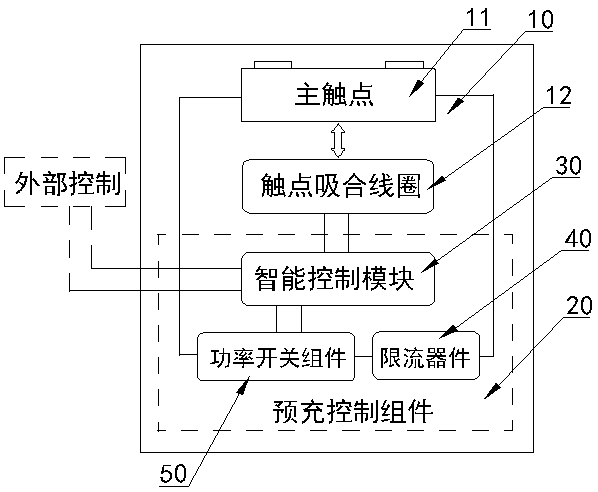

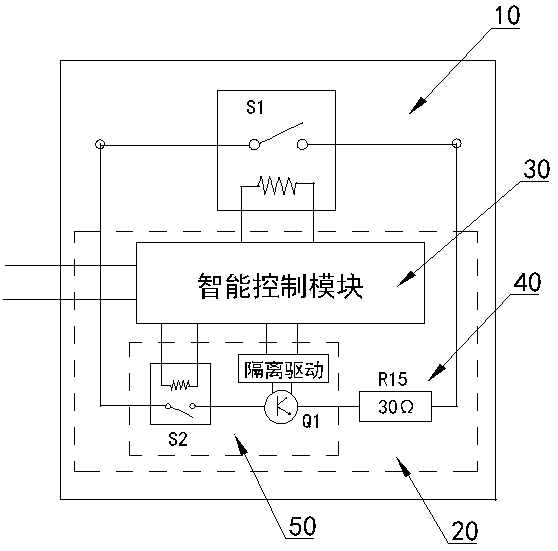

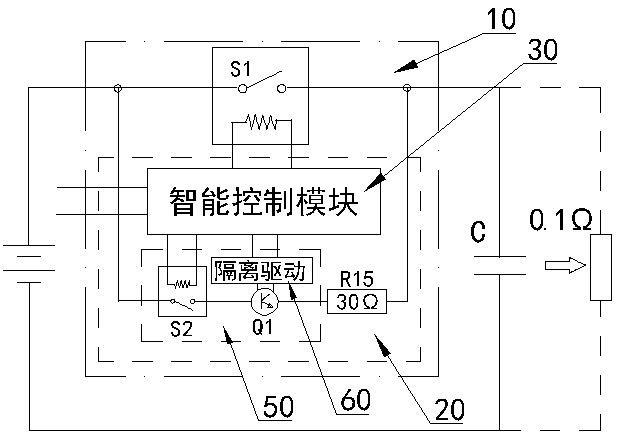

[0023] figure 1 , figure 2 , image 3 , Figure 4In the shown embodiment, a capacitive load high-current surge type DC relay includes a main relay S1 with a main contact 11 and a contact pull-in coil 12, and also includes a pre-charging control assembly 20, the pre-charging The charging control assembly 20 includes an intelligent control module 30, a power switch assembly 50 and a current limiting device 40, and the power switch assembly 50 includes a second relay S2, a first power switch tube Q1 and an isolation driver 60 module, the second relay coil and The intelligent control modules are electrically connected, and the first power switch tube Q1 is electrically connected to the intelligent control module 30 through the isolation drive 60 module. After the power switch assembly 50 and the current limiting device 40 are connected in series, both ends of the main contact 11 of the main relay S1 are connected to each other. Parallel electrical connection; when the relay i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com