Jack connection current collecting socket based on copper substrate

A copper base and socket technology, used in connection, conductive connection, electrical component connection, etc., can solve the problems that the crimp terminal space cannot meet the product assembly requirements, the flux cannot be cleaned, and the joints are corroded, so as to avoid flux residues. , The effect of improving processing reliability and short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

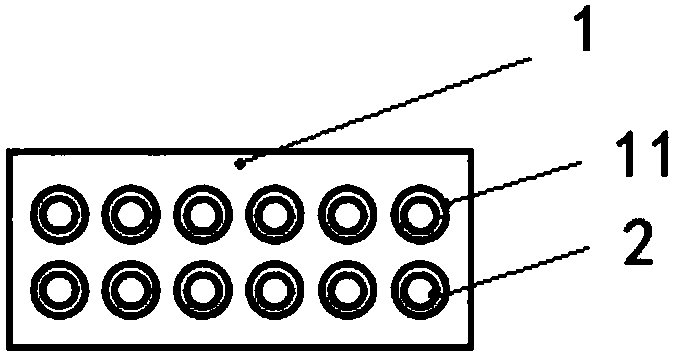

[0015] This embodiment provides a socket connection confluence socket based on a copper substrate, the socket includes a base 1, a first elastic contact body 2 and a second elastic contact body 2, the base 1 is made of copper casting, and its external dimensions are 14.2mmX10mmX5mm. Its upper surface is provided with 12 upper holes 11 side by side, which are neatly arranged in two rows. The center distance between two adjacent holes is 2.2mm, and the distance between the upper holes 11 can ensure the installation of the two 0.2mm wires.

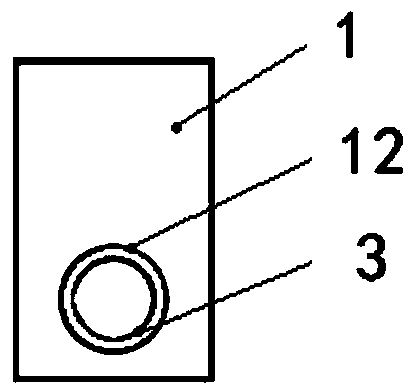

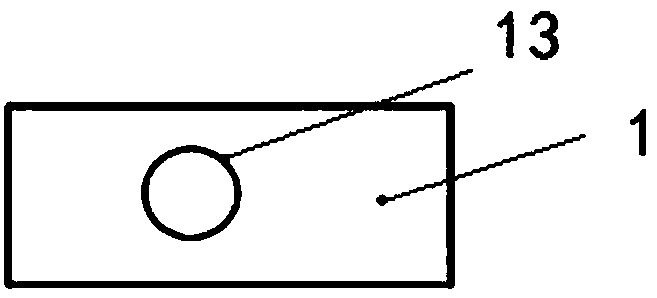

[0016] A first elastic contact body 2 is installed in the upper hole 11, and the diameter of the first elastic contact body 2 is 1 mm. A side hole 12 is provided on the lower half of one side of the base 1 , the center of the side hole 12 is 2.5 mm away from the bottom surface, and its center point is located on the longitudinal centerline of the side. A second elastic contact body 3 is installed in the side hole 12, and the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com