Foam stabilizer composition and foamed cement slurry and preparation method thereof

A technology of composition and foam stabilizer, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high compressive strength of cement stone, poor foam stability, low density, etc., and achieve high compressive strength, High foam stability, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

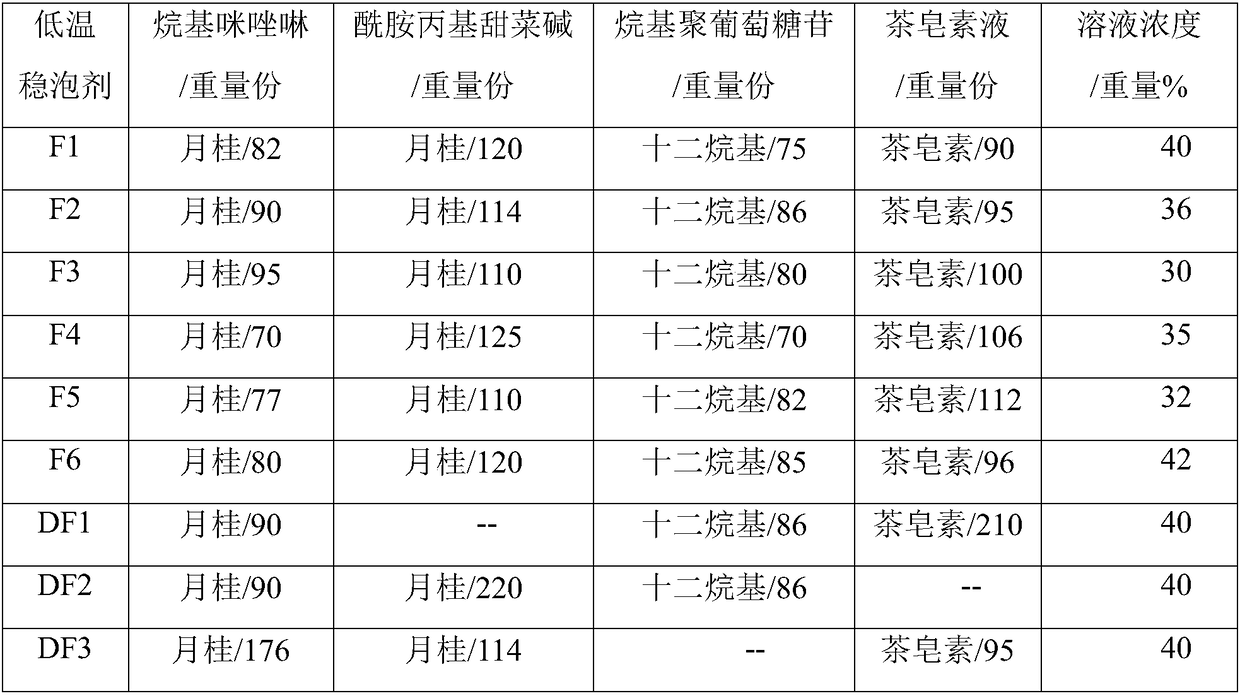

[0073] This example serves to illustrate the foam stabilizer composition.

[0074] According to the formula shown in Table 1, the listed alkyl imidazoline compounds, betaine compounds, alkyl polyglucoside compounds, tea saponin liquid and appropriate water are configured into aqueous solutions of corresponding concentrations, respectively to obtain stable Foaming agents F1-F6.

Embodiment 2

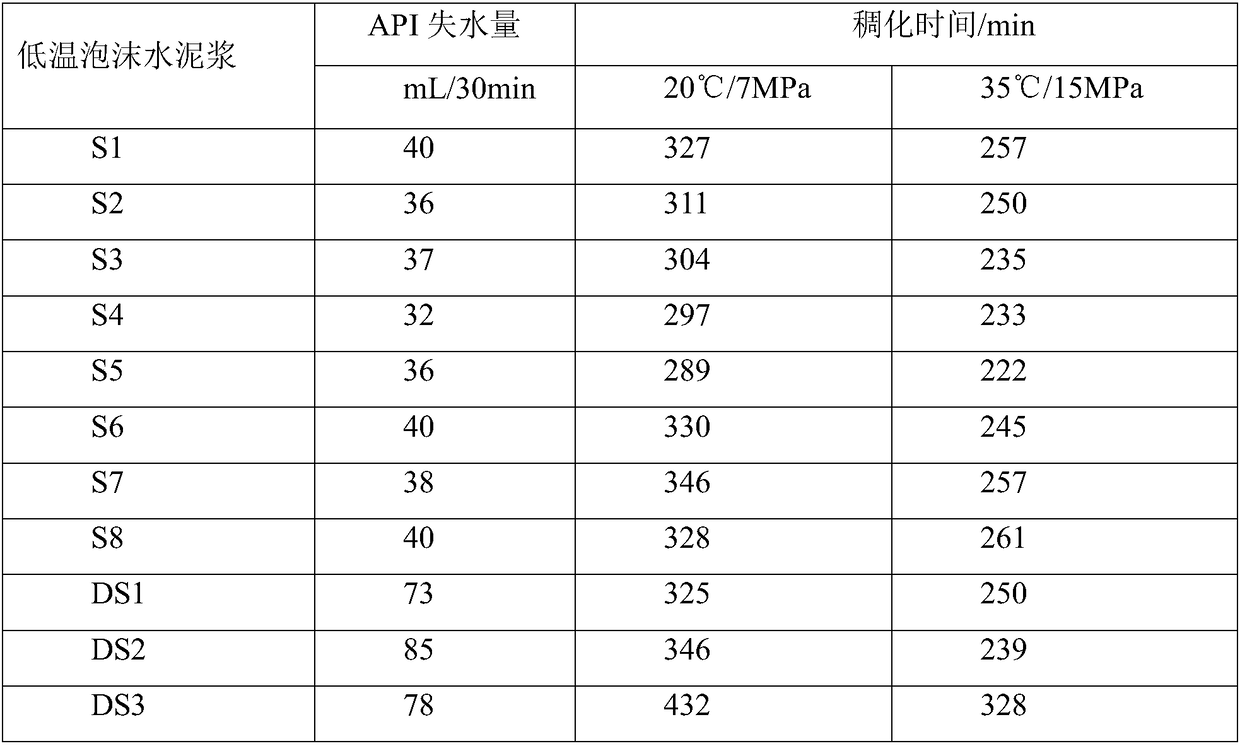

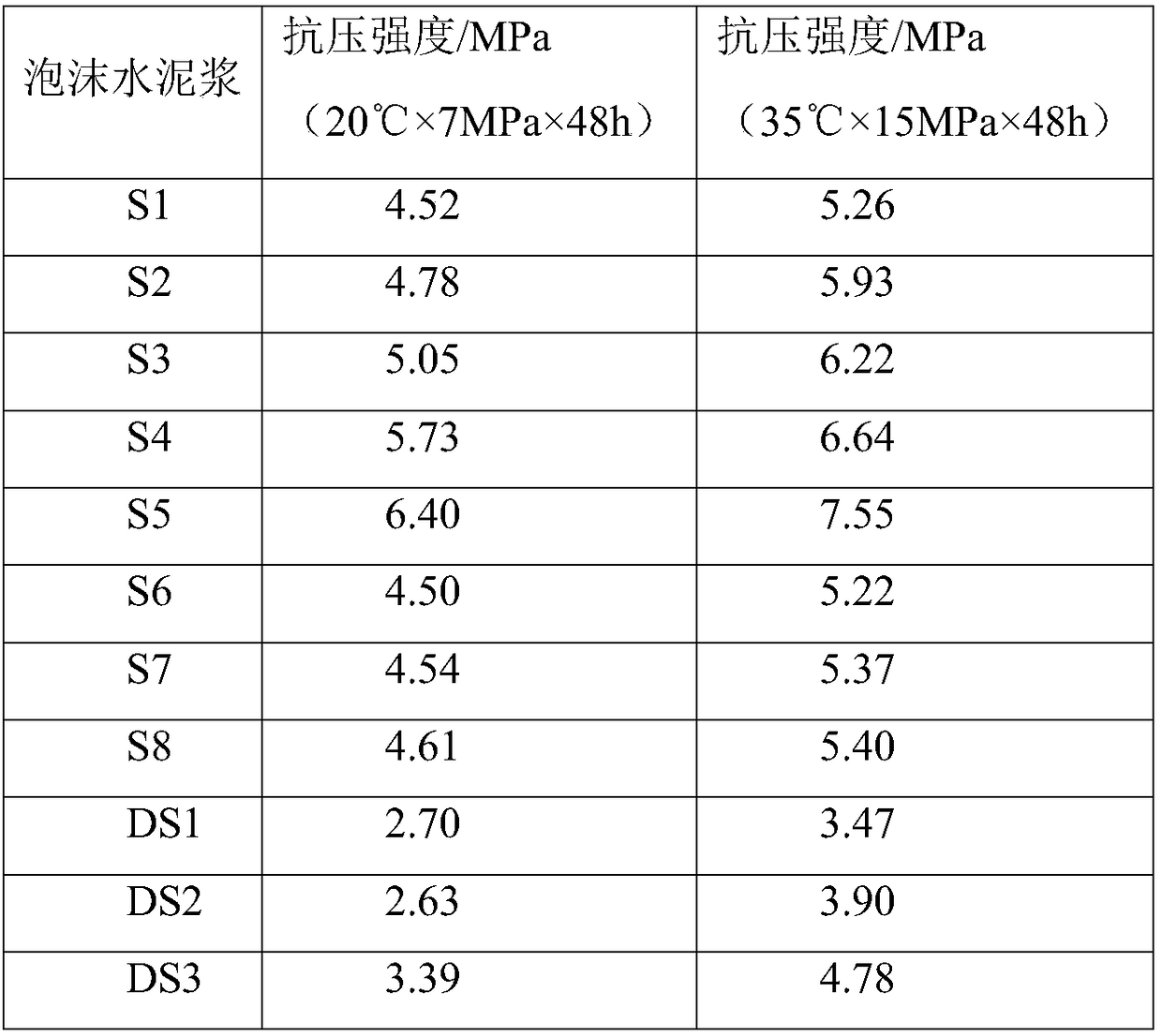

[0086] This example is used to illustrate the foamed cement slurry of the present invention.

[0087] According to the method of foam cement slurry embodiment 1, the difference is that the first gas generating agent adopts dihydrazide carbonate instead of hydrazine, the second gas generating agent adopts sodium chlorite instead of chlorine dioxide, and the foam stabilizer adopts foam stabilizer F2 replaces F1 to obtain foam cement slurry S2 with a density of 0.90 g / cm 3 , wherein, excluding the solvent component, the weight ratio of cement, the first air-generating agent, the second air-generating agent, foam stabilizer, low-temperature strengthening agent, water loss reducing agent, dispersant, early strength agent and water consumption is 100: 0.45:0.93:1.5:10:1.55:0.3:3.5:58.

Embodiment 3

[0089] This example is used to illustrate the foamed cement slurry of the present invention.

[0090] According to the method of foamed cement slurry embodiment 1, the difference is that the first gas-generating agent adopts hydroxylamine hydrochloride to replace hydrazine, the second gas-generating agent adopts potassium chlorite to replace chlorine dioxide, and the foam stabilizer adopts foam stabilizer F3 to replace F1, Thereby obtain foam cement slurry S3, its density is 1.14g / cm 3 , wherein, excluding the solvent component, the weight ratio of cement, the first air-generating agent, the second air-generating agent, foam stabilizer, low-temperature strengthening agent, water loss reducing agent, dispersant, early strength agent and water consumption is 100: 0.42:0.88:1.4:9:1.5:0.3:3.2:54.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com