Large and medium-sized kitchen waste heat recovery and utilization system

A waste heat recovery, large and medium-sized technology, applied in applications, heating methods, household heating, etc., can solve problems such as heat loss, difficulty in implementation, environmental heat pollution, etc., achieve high practicability and economy, avoid energy waste, cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

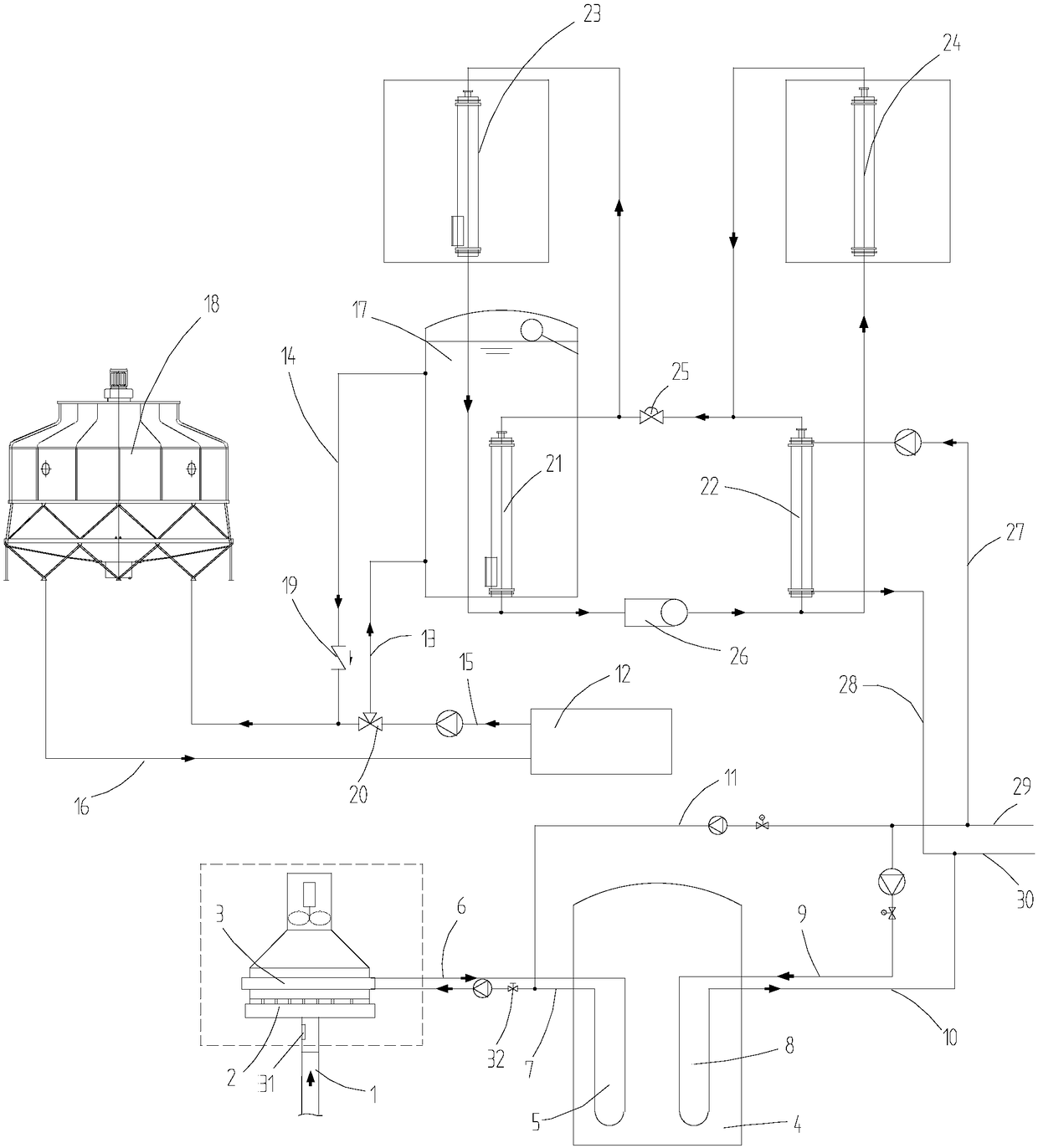

[0021] as attached figure 1 The shown large and medium-sized kitchen waste heat recovery system includes comprehensive recovery and utilization of the waste heat in the main flue, the waste heat generated by the refrigerator unit in the kitchen, and the waste heat of the air in the kitchen. The system of the present invention mainly includes smoke Gas heat recovery device and phase change heat storage tank 4, the phase change heat storage tank 4 is filled with No. 58 paraffin as phase change material, the phase change heat storage tank 4 is provided with a first water tank 5 and a second water tank 8, the second A water tank 5 communicates with the flue gas heat recovery device through the first water inlet pipe 6 and the first water outlet pipe 7 to form a circulating water circuit. The second water tank 8 communicates with the tap water supply pipe 29 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com