Low-temperature high-vacuum combination heating table

A composite heating and high vacuum technology, which is applied in the direction of electric heating devices, material thermal analysis, metal processing equipment, etc., can solve the problems of inaccurate temperature control, few observation windows, and difficulty in observing the brazing of diamond tools, etc. The effect of production accuracy and ease of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

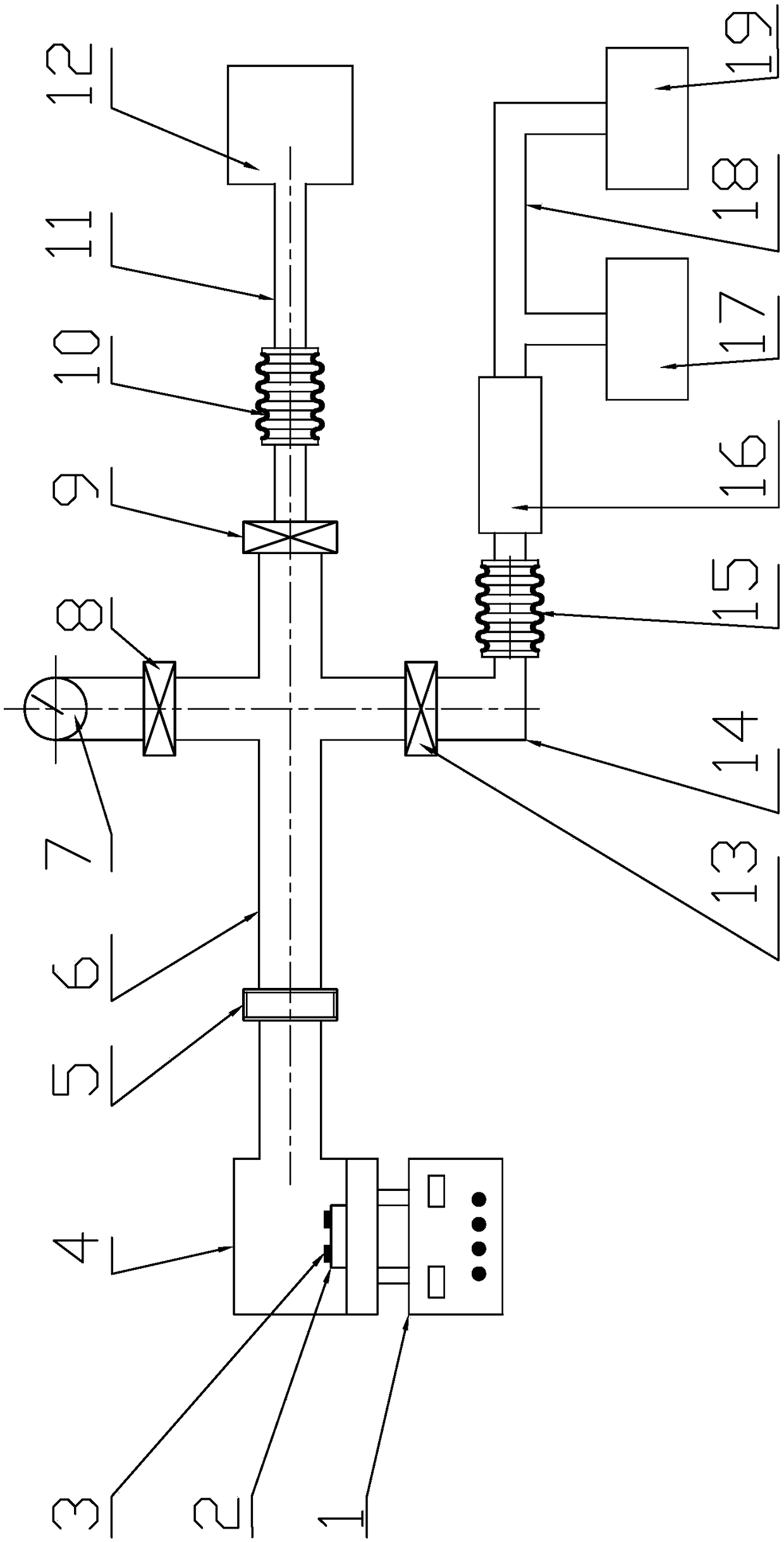

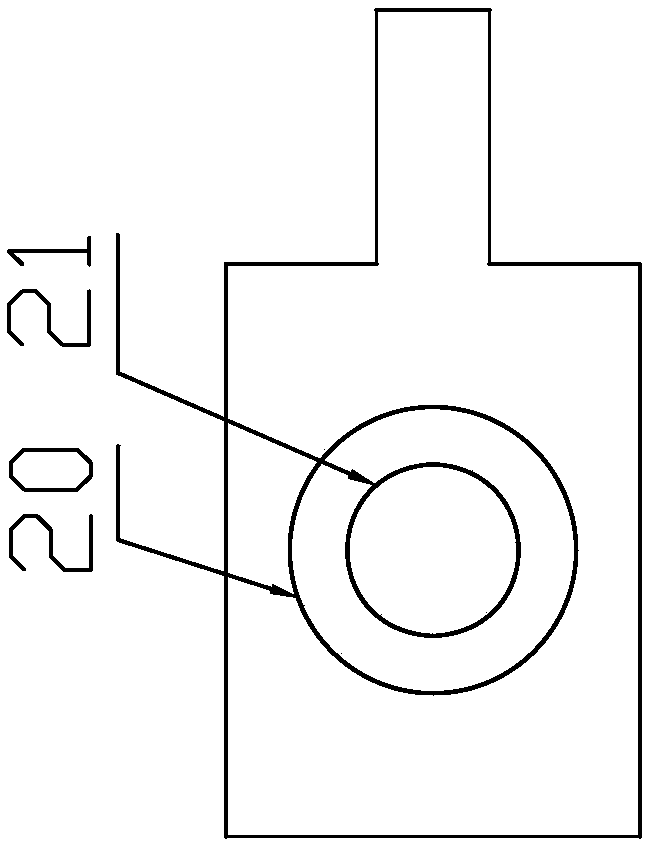

[0034] Low temperature and high vacuum composite heating table, please refer to figure 1 , figure 2 and image 3 , including a heating table 1, a quartz base 2, a vacuum protection cover 4, a variable diameter tube 5, a four-way tube 6, a vacuum gauge 7, an air release valve 8, a first control valve 9, a protective gas pipeline 11, and a rare protective gas The protective gas storage tank 12, the second control valve 13, the vacuum pipeline 14, the control system 16, the vacuum pump 17, the exhaust pipeline 18, the molecular pump 19 and the vacuum protection cover 20.

[0035] The vacuum protection cover 4 is provided with an opening, and the vacuum protection cover 20 is connected to the vacuum protection cover 4 so as to open the opening to take the sample sample 3 or close the opening to seal the opening. 20 is provided with a viewing window 21, such as the cover 20 is provided with a through hole, and the viewing window 21 is sealed and fixed in the through hole. In a ...

Embodiment 2

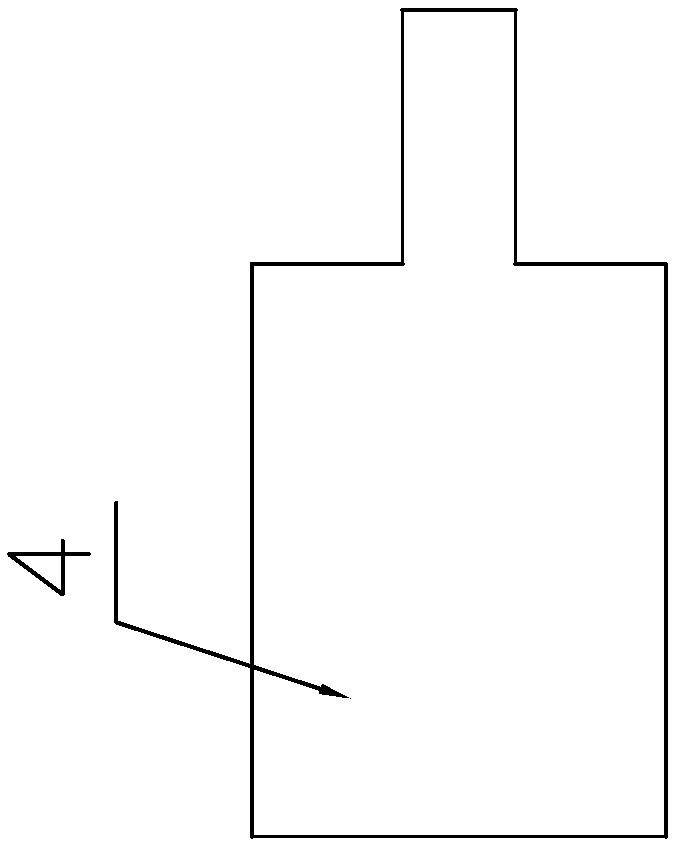

[0043] Low temperature and high vacuum composite heating table, please refer to Figure 4 and Figure 5 , it differs from Embodiment 1 in that: the heating platform 1 is located inside the vacuum protection cover 4 as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com