Trackless rubber-tyred vehicle intelligent onboard system, downhole vehicle dispatching system and control method

A technology for trackless rubber-tired vehicles and on-board systems, which is applied in the field of intelligent on-board systems for trackless rubber-tired vehicles, can solve the problems of difficulty in autonomous driving of vehicles, insufficient perception and positioning reliability, limited drivable area, and limited range of turning and avoidance. Achieve overall coordination and intelligent scheduling, ensure reliable perception and positioning capabilities, and improve the effect of autonomy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

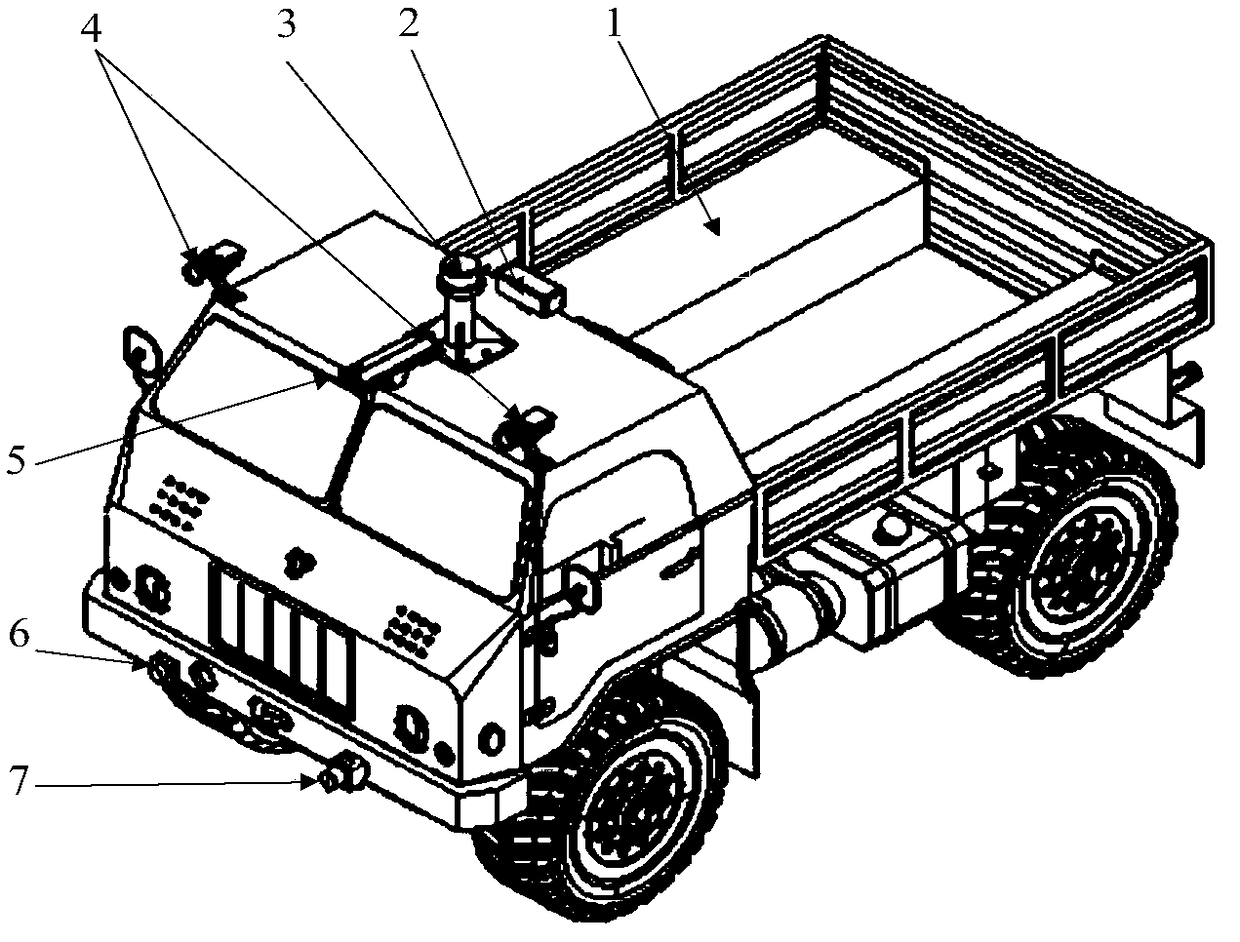

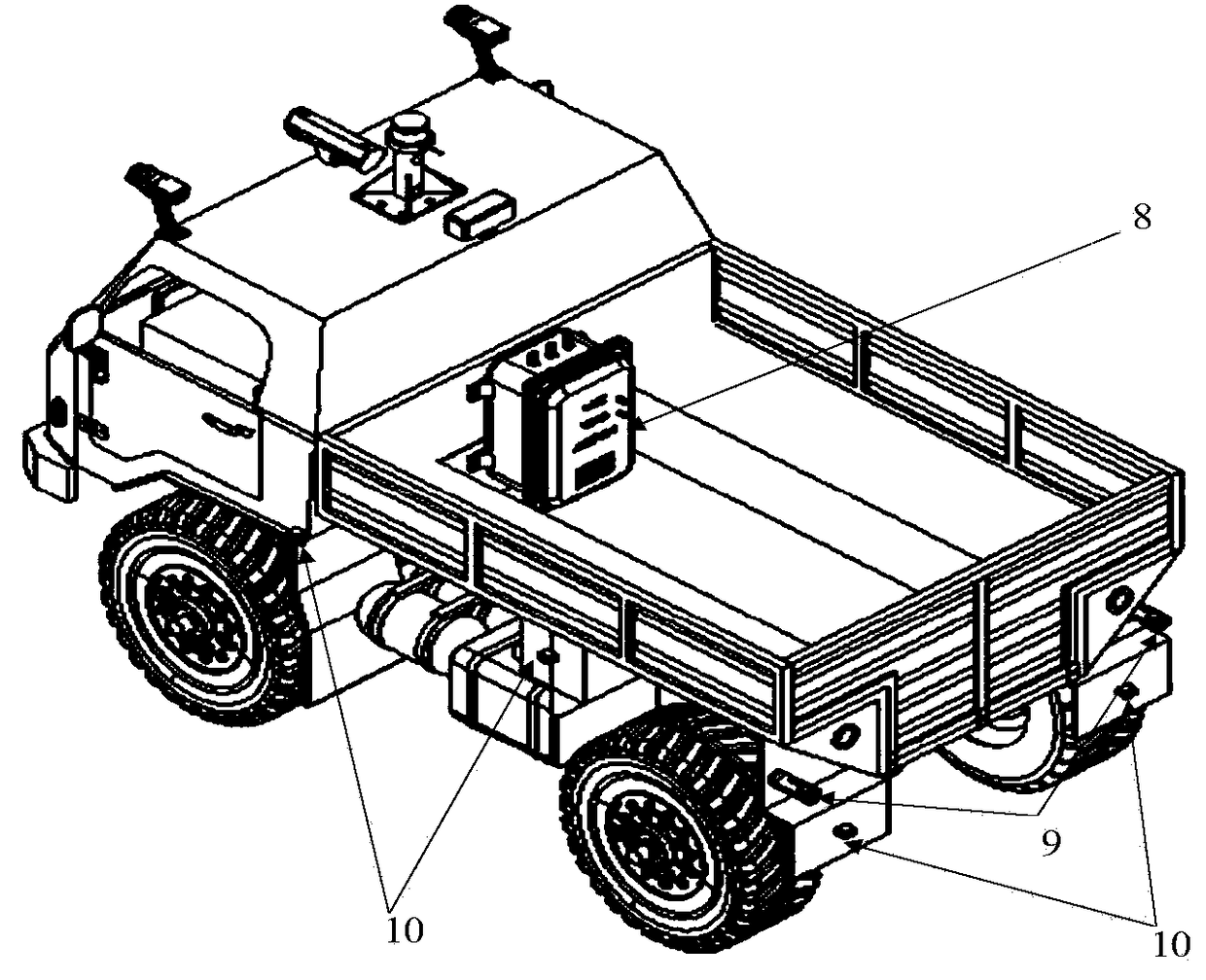

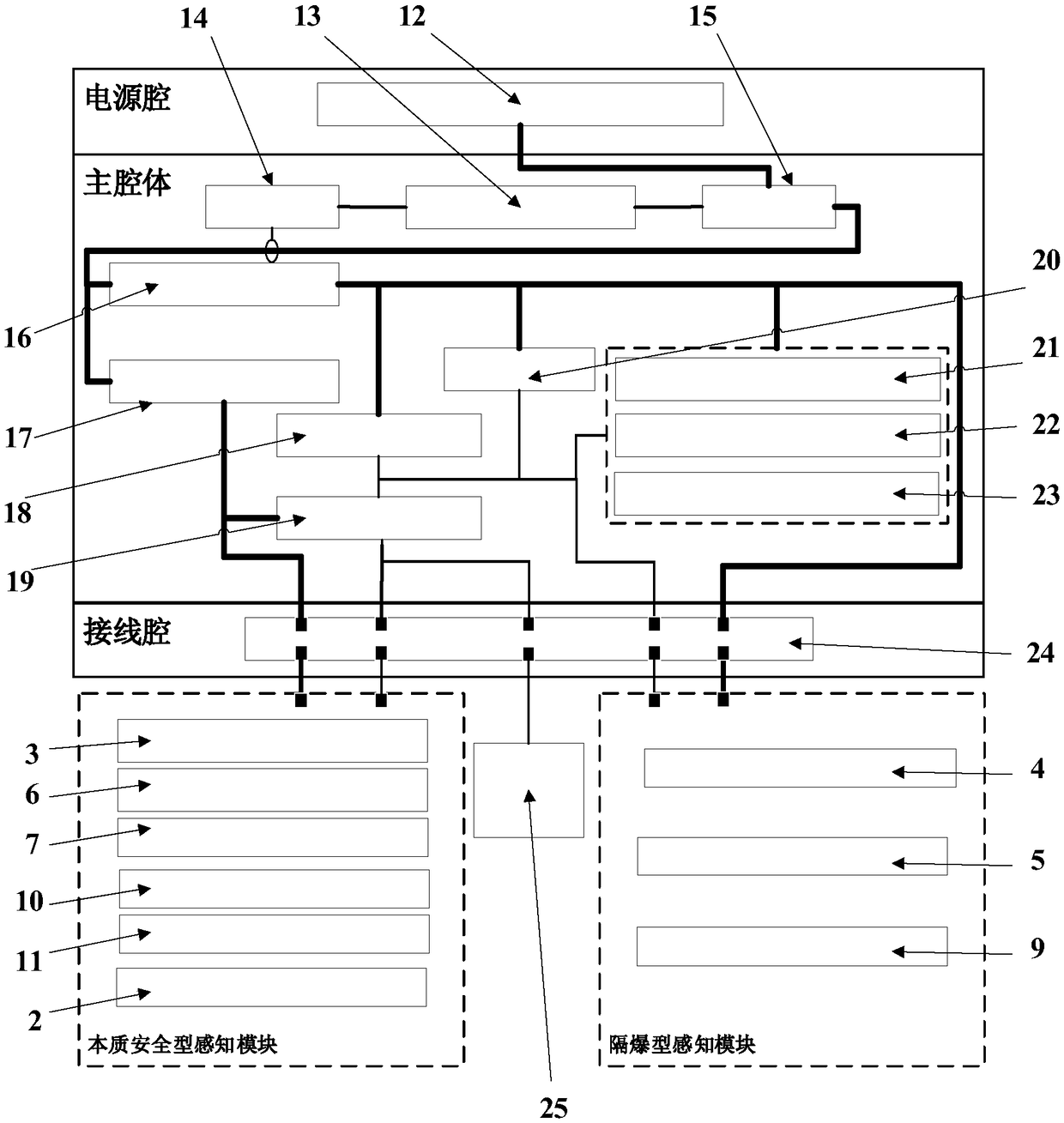

[0040] Such as figure 1 and figure 2 As shown, the trackless rubber-tyred car intelligent on-board system designed by the present invention includes a trackless rubber-tyred car 1, a wireless sensor network node module 2, a multi-line laser radar sensing module 3, an explosion-proof infrared camera module 4, and an explosion-proof infrared night vision instrument module 5, millimeter-wave radar sensing module 6, two-dimensional laser radar sensing module 7, explosion-proof control cabinet 8, flame-proof TOF camera sensing module 9, vehicle-mounted sonar sensing module 10, and speed measurement module 11. Among them, the multi-line laser radar sensing module 3 is installed on the upper part of the trackless rubber-tyred vehicle 1, the two-dimensional laser radar sensing module 7 and the millimeter-wave radar sensing module 6 are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com