Electric dust collector having overlapping collector cell units

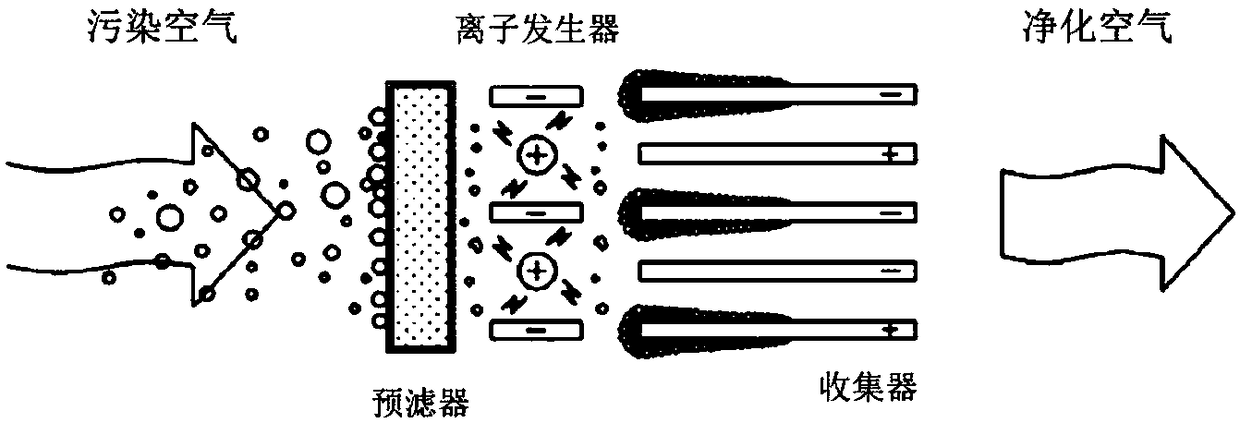

An electrostatic precipitator and collector technology, applied in the direction of electrode structure, electrostatic separation, electrostatic separation cover, etc., can solve the problems of difficult assembly operations, difficult repair and assembly, and reduced cleaning efficiency, and achieve easy product manufacturing and management. The effect of increasing the foreign matter adsorption efficiency and prolonging the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

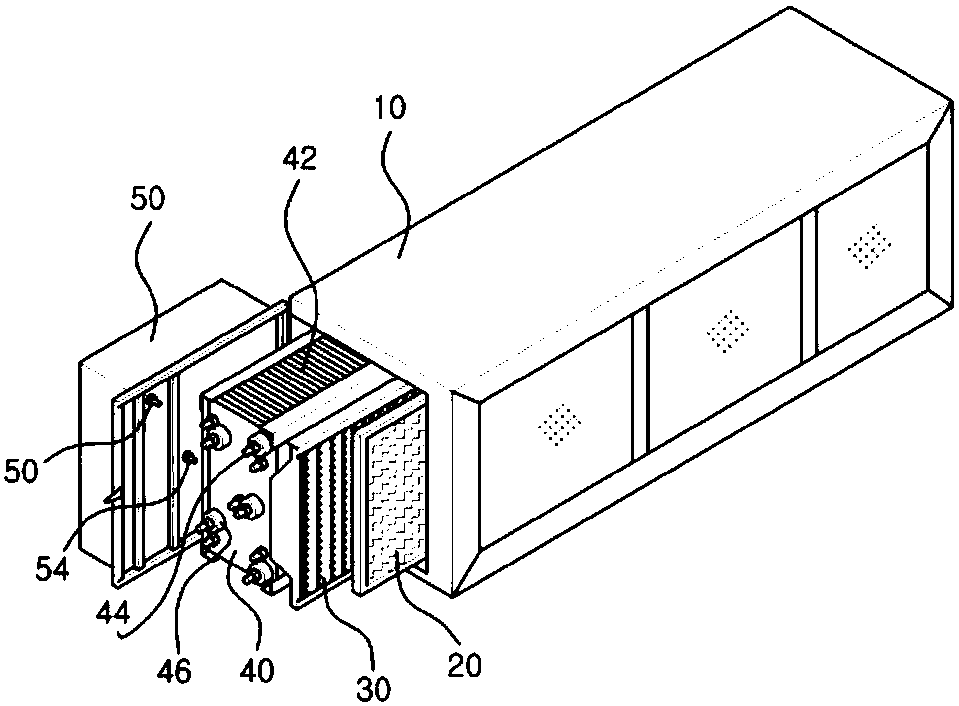

[0055] The specific technical idea of the present invention will be described below with reference to the accompanying drawings.

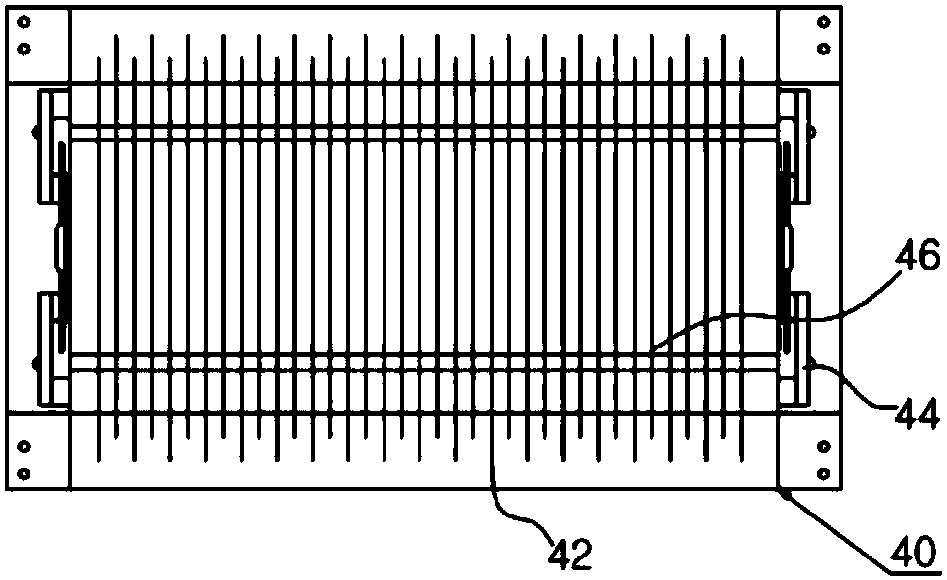

[0056] According to the present invention, a rectangular cell plate with a large surface area is provided with a large-diameter hole so that it does not contact the rods passing through the cell plate, and a small-diameter hole is provided, and the large-diameter hole and the small-diameter hole are close to each other to form a Yes, formed in multiple places on the cell plate, which is divided into "+" voltage cell plates that maintain electrical contact with the rod on the high voltage side and "-" voltage cell plates that are in contact with the ground side They overlap each other alternately, and are sequentially inserted into the respective rods at certain intervals through spacers, and the two ends are fastened to the end plates with nuts to form a small cell plate 400, which is separated by spacers 500 of the same specification and has a L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com