Ball return means with a fastening sleeve which can be mounted axially

A return device, ball technology, applied in the direction of transmission, steering mechanism, transportation and packaging, etc., can solve the jam, part of the pulley may reach between the main body and the deflector, prevent the ball nut from rotating, hinder, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

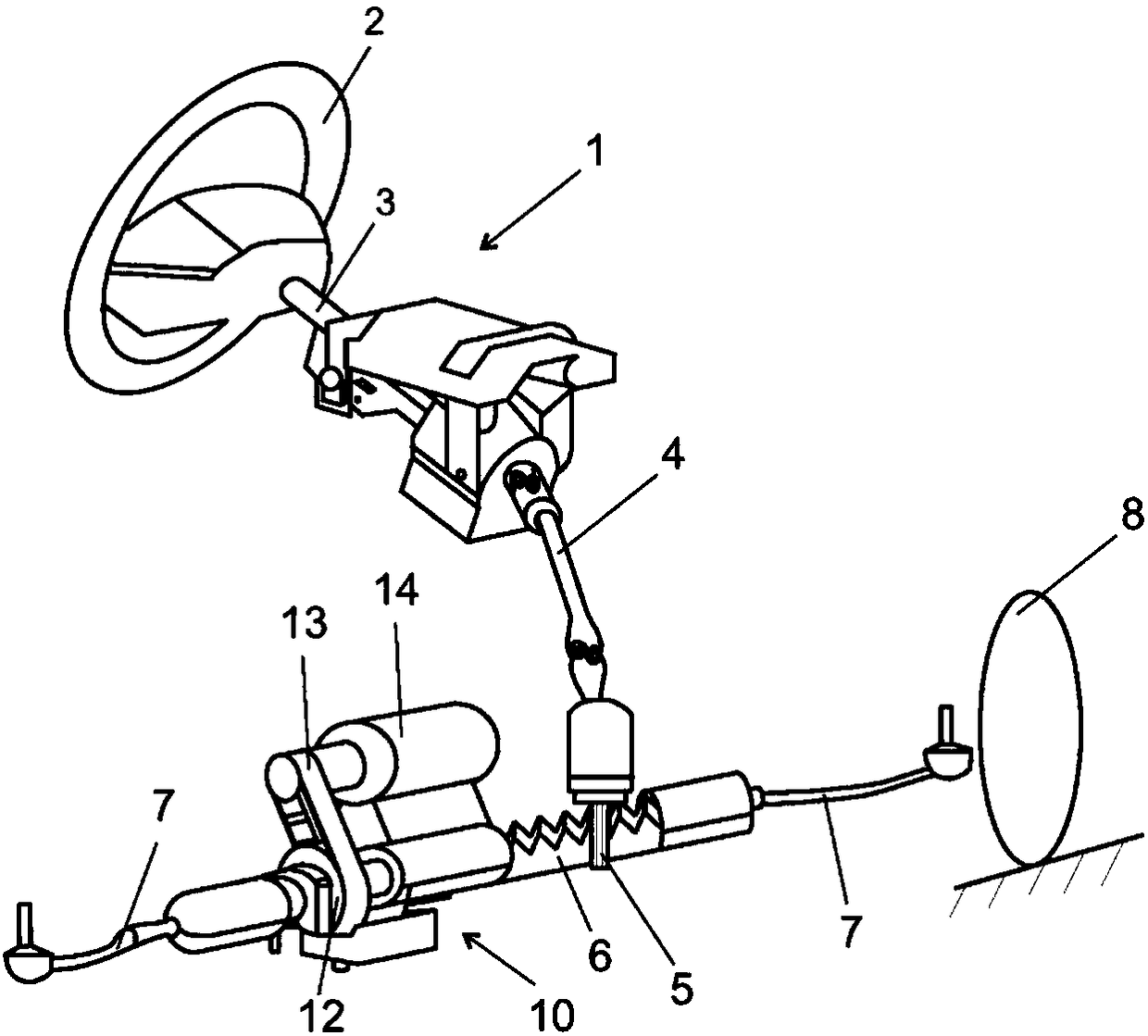

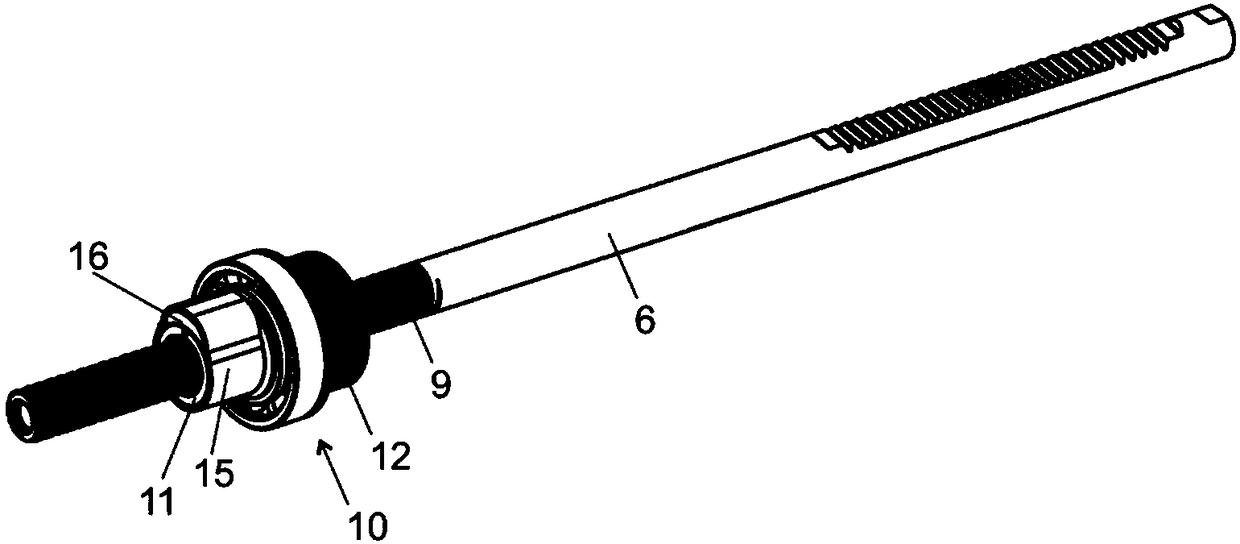

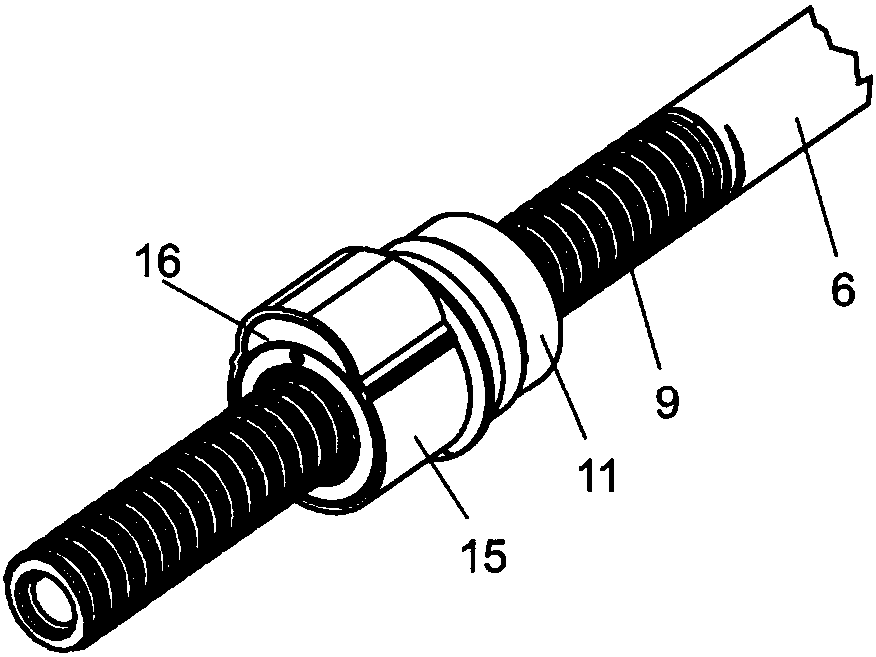

[0024] exist figure 1 In , an electromechanical motor vehicle steering system 1 is schematically shown having a steering wheel 2 coupled for common rotation to an upper steering shaft 3 and a lower steering shaft 4 . The lower steering shaft 4 is connected to a pinion 5 for common rotation. The pinion 5 meshes with the toothed segment of the rack 6 in a known manner. The rack 6 is mounted in the steering housing in such a way that it can move in the direction of its longitudinal axis. At its free end, the toothed rack 6 is connected to a steering rod 7 via a ball joint (not shown). The steering rod 7 is itself connected in a known manner to steered wheels 8 of the motor vehicle via a steering knuckle. Rotation of the steering wheel 2 through the connection of the steering shafts 3 , 4 and the pinion 5 leads to a longitudinal movement of the rack 6 and thus to a pivoting of the steering wheel 8 . On the outside of the rack 6 there is provided a ball screw thread 9 as part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com