Battery cell module having cooling element

A battery module and cooling element technology, which is applied in the field of battery modules with cooling elements, can solve the problems of inability to arbitrarily expand the total power and increase the quality of cost battery module components, and achieve the effects of quality reduction, low-cost manufacturing, and long-lasting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the battery module of the present invention are described with reference to the drawings.

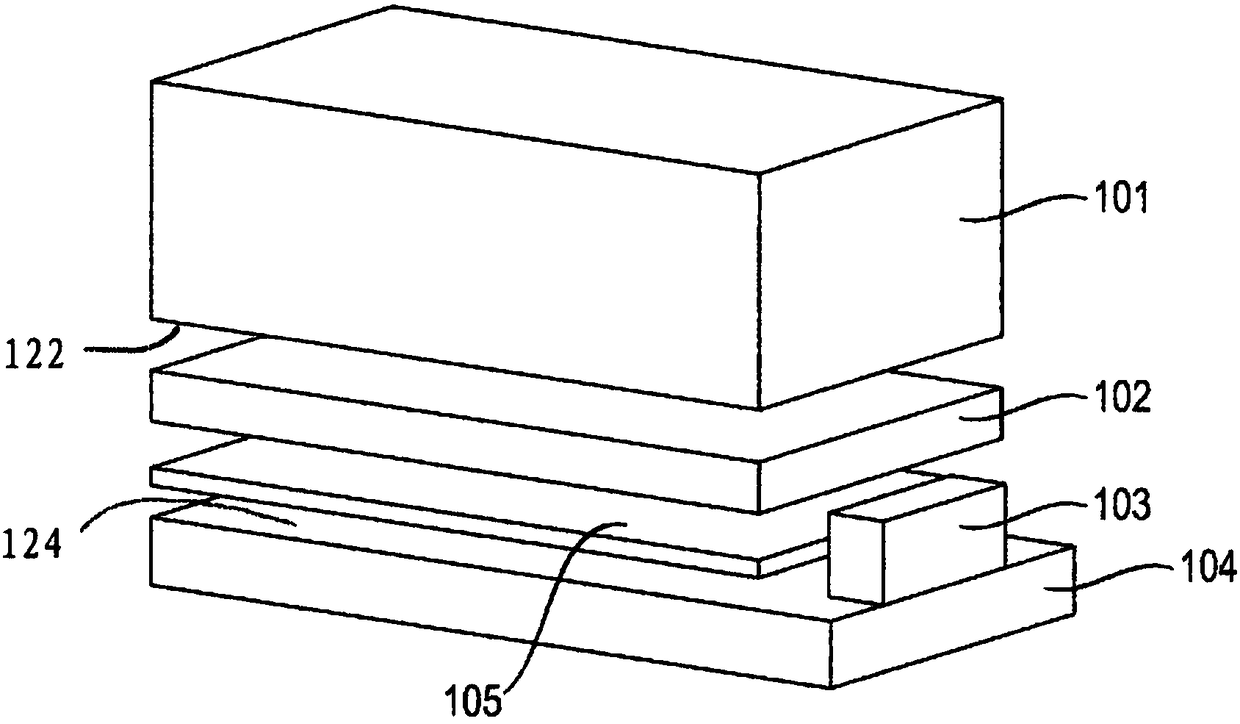

[0031] figure 1 Shows a side view of a first embodiment of a battery module according to the invention, in which a battery pack 101 with a battery stack and a cooling element designed as a cooling plate 104 are formed on one of their surfaces by a heat-conducting casting as a heat-conducting layer The material layer 102 is connected to a high voltage insulating layer 105 as a voltage insulating layer. Here, the heat-conducting potting compound layer 102 is glued to the lower surface of the battery pack 101 , which forms the first cooler connection surface 122 , while the high-voltage insulating layer 105 is glued to the upper surface of the cooling plate 104 serving as the cooling surface 124 On the surface. A material-bonded connection is thus achieved between the battery pack 101 and the cooling plate 104 by direct bonding.

[0032] Optionally, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com