Integrally-formed shredder blade and production method thereof

A production method and shredder technology, applied in grain processing and other directions, can solve the problems of different sizes of plastic fragments, inability to meet production, blade wear, etc., and achieve the effect of simple structure, reasonable design and reduced wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

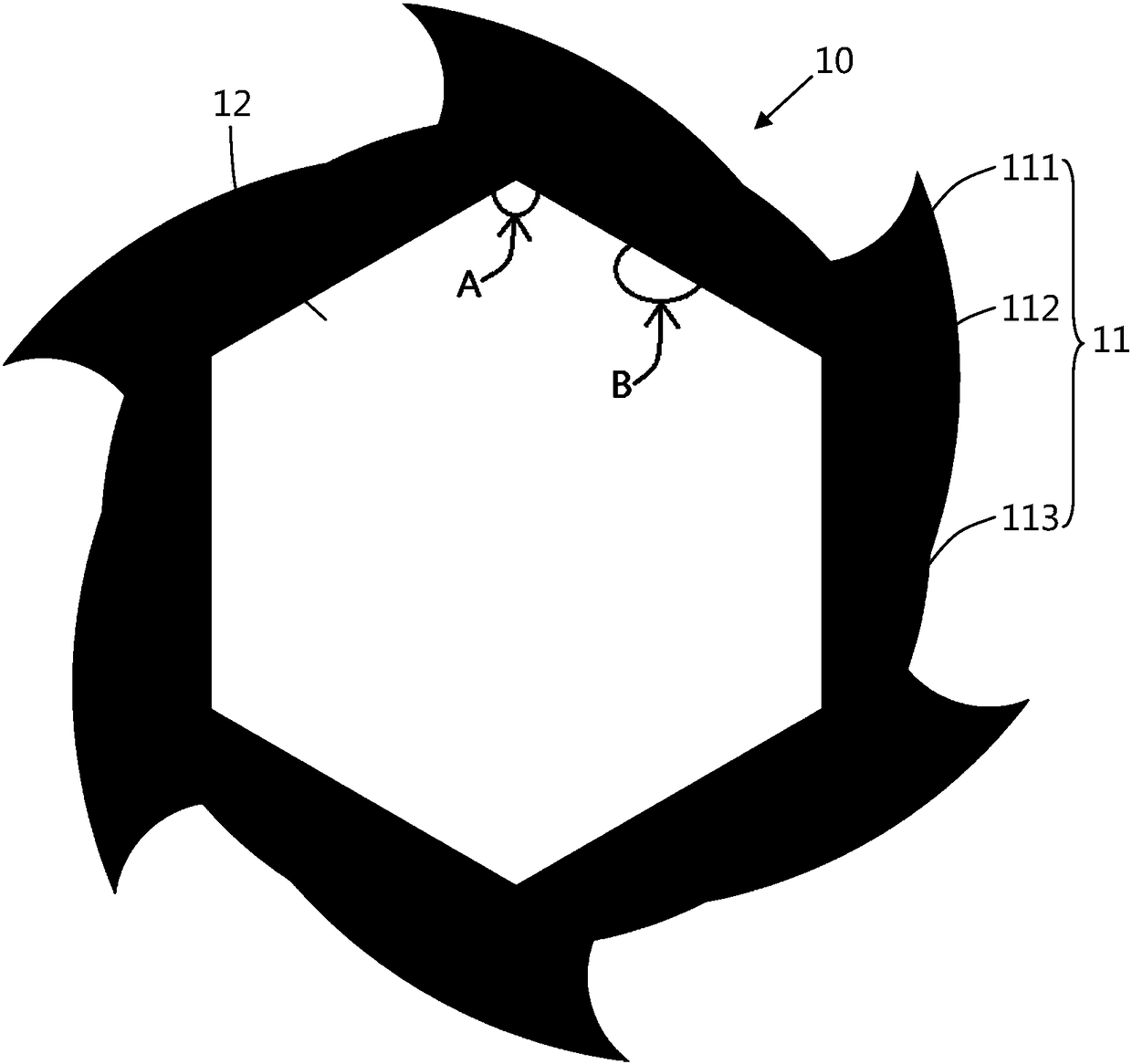

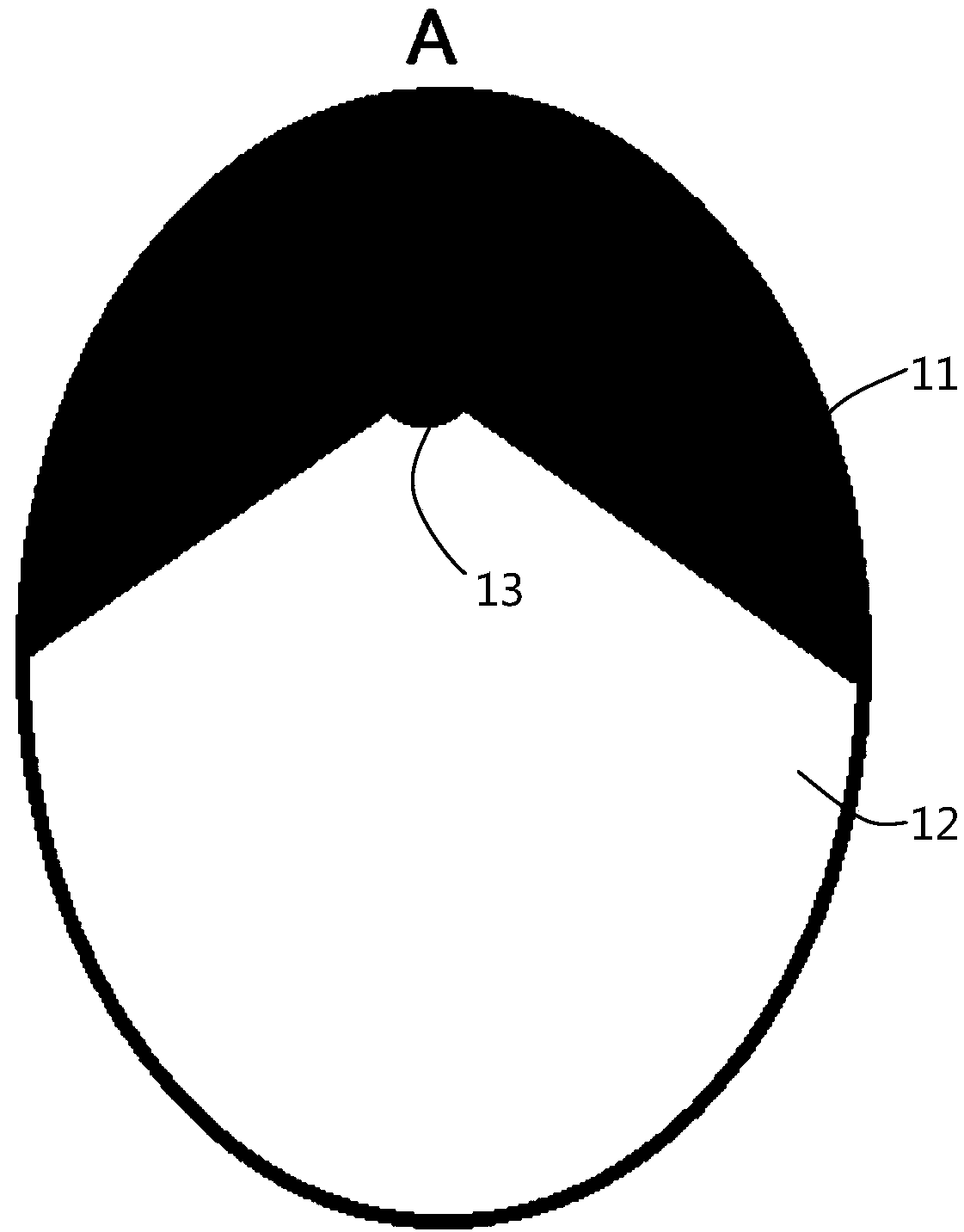

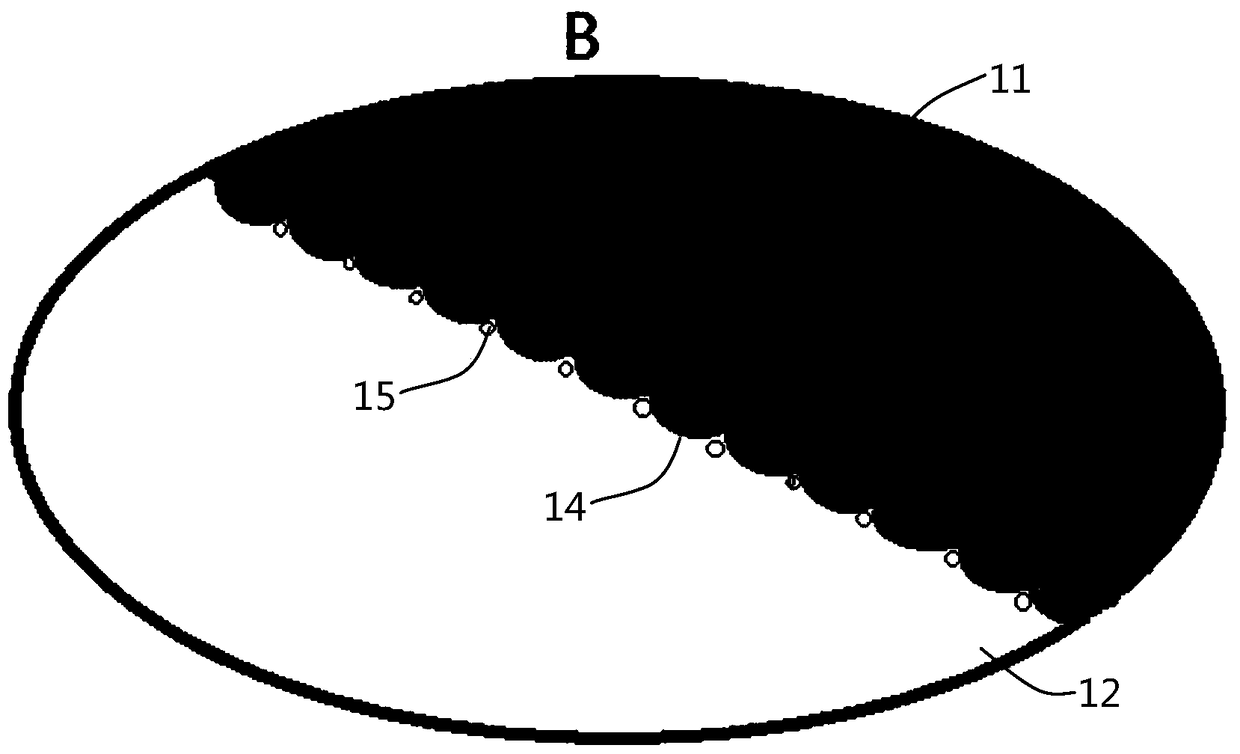

[0040] Such as Figure 1 to Figure 3 As shown, an integrally formed shredder blade of this embodiment includes a blade body 10, a blade 11 is provided on the blade body 10, and a connecting hole 12 is opened in the center of the blade body 10, and the shape of the connecting hole 12 is positive n sides Shape, wherein 12≥n≥5, the edges and corners of the regular n-gon are connected by arc protrusions 13. Preferably, n=6, the shape of the connection hole 12 is a regular hexagon, and the number of blades 11 is six, wherein the blades 11 are arranged corresponding to each side of the regular hexagon.

[0041]Currently used as a shredder blade disclosed in Patent Document 1, the blade is a split type, the structure is complicated, the manufacturing process is cumbersome, the cost is greatly increased, and it is not conducive to the market competition of the enterprise, while the blade of this embodiment is an integral type The manufacturing process is simple; a cutter head and a s...

Embodiment 2

[0047] A production method of an integrally formed shredder blade in this embodiment comprises the following steps:

[0048] Step S101, selecting Cr12Mo1V1 or W6Mo5Cr4V2 steel, stamping or forging to obtain a blade blank;

[0049] Step S102, performing rough grinding on the blade blank, leaving a margin of 0.7mm;

[0050] Step S103, heat-treat the roughly ground blade blank, first heat it to 550°C, then keep it warm for 1.5 hours, then heat it to 720°C, keep it warm for 3 hours, then heat it to 900°C, keep it warm for 40 minutes, then quench, oil quench, and cool After cryogenic treatment, the temperature of cryogenic treatment is -210°C, keep it for 1.5h, return to normal temperature in the air, temper once, the tempering temperature is 160°C, cool to normal temperature, place it for 1.5h, and then perform secondary tempering , the tempering temperature is 200°C;

[0051] Step S104, first remove the oxide layer on the surface of the mold after the treatment in step S103, la...

Embodiment 3

[0054] A production method of an integrally formed shredder blade in this embodiment comprises the following steps:

[0055] Step S101, selecting W6Mo5Cr4V2 steel material, stamping or forging to obtain a blade blank;

[0056] Step S102, performing rough grinding on the blade blank, leaving a margin of 0.7 mm;

[0057] Step S103, heat-treating the roughly ground blade blank, first heating to 540°C, then holding for 2 hours, then heating to 710°C, holding for 2.5 hours, then heating to 900°C, holding for 35 minutes, then quenching, oil quenching, and cooling After cryogenic treatment, the temperature of cryogenic treatment is -220°C, keep it for 1.5h, return to normal temperature in the air, temper once, the tempering temperature is 160°C, cool to normal temperature and place it for 1.5h, and then perform second tempering , the tempering temperature is 180°C;

[0058] Step S104, first remove the oxide layer on the surface of the mold after the treatment in step S103, laser cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com