Spherical powder material for 3D printing and preparation method of spherical powder material

A spherical powder and 3D printing technology, applied in the field of 3D printing, can solve the problems of easy bonding of resin powder, difficult fluidity to meet the requirements, and low sphericity of 3D printing powder, so as to achieve easy emulsification, improve smoothness, and fluidity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

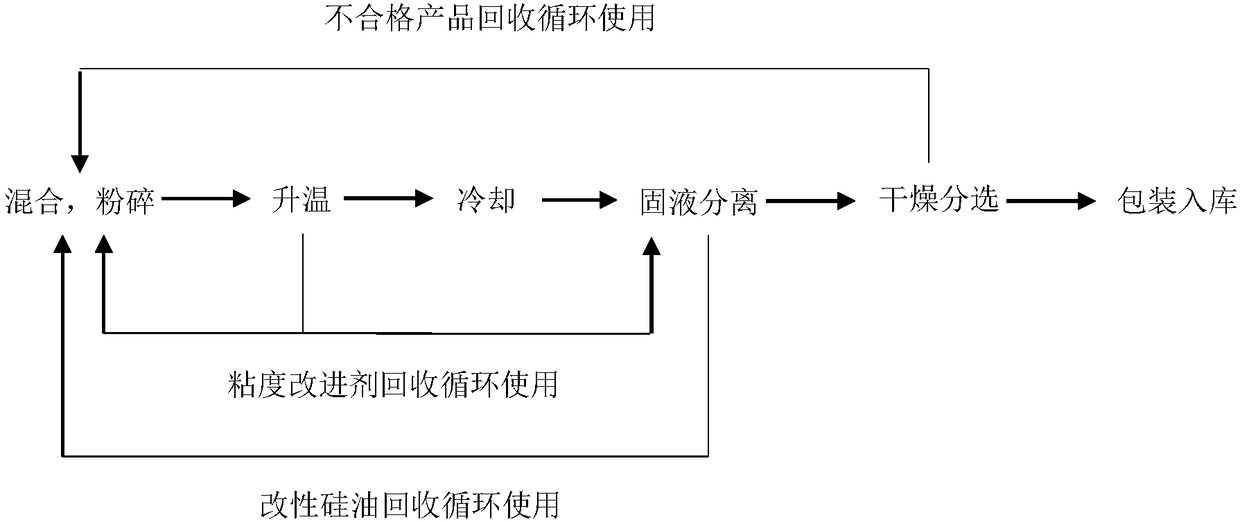

[0034] The present invention also provides a method for preparing a spherical powder material for 3D printing, comprising the following steps:

[0035] S1, the raw materials are mixed in the reactor, and then pulverized;

[0036] S2, heating up to 10°C-100°C above the melting point of the thermoplastic resin;

[0037] S3, cooling, separating, and drying to obtain a spherical powder product.

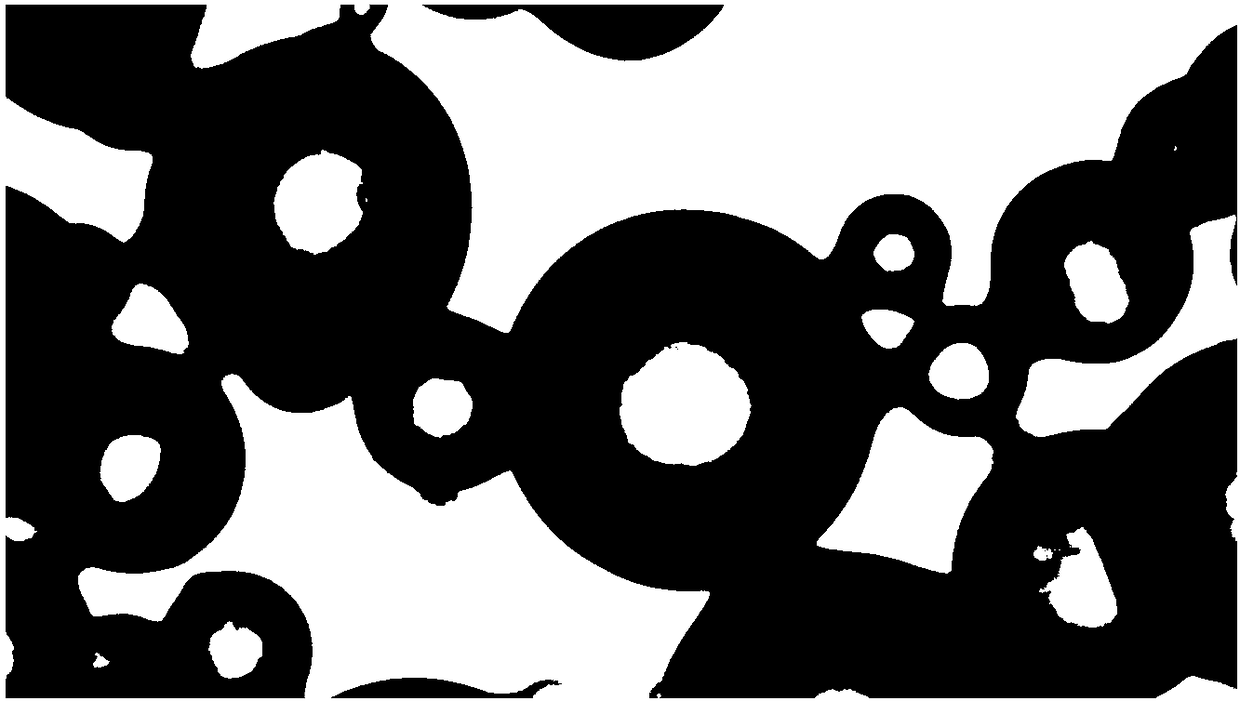

[0038] The preparation method of the spherical powder material for 3D printing in the present invention combines the advantages of the crushing method and the emulsification method. First, it is crushed in a solvent, which can reduce the temperature rise of the crushing and avoid the agglomeration of the bonded crushing tool and thermoplastic resin powder. , The thermoplastic resin powder is dispersed and emulsified in a modified silicone oil solvent (or a mixed solvent with low boiling point silicone oil), and after cooling, it can form a spherical structure and improve fluidity.

[0039...

Embodiment 1

[0047] Take 100 kg of low-density polyethylene (HDPE) resin, 250 kg of cyanosilicone oil, 100 kg of kerosene, and 2 kg of emulsifier into the emulsification kettle, heat it to about 100 degrees, start the emulsifier to shear and pulverize for 1.5 hours, and put it under the protection of nitrogen Gradually raise the temperature to about 160 degrees to emulsify for 4 hours, cool, separate with a bag centrifuge, wash with water, dry, sort and compound, and pack for shipment.

Embodiment 2

[0049] Take 100 kg of polypropylene resin, 250 kg of water-based silicone oil, 100 kg of methyl oil, and 2 kg of emulsifier into the emulsification kettle, heat to about 100 degrees, start the emulsifier to shear and pulverize for 4 hours, and gradually heat up to Emulsify at about 200 degrees for 5 hours, cool, continue solid-liquid separation, wash with water, dry, sort and compound, pack and ship.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com