Preparation method for in-situ generation of MgO dispersion strengthened ultra-fine grain Al-Mg alloy

A dispersion strengthening and in-situ generation technology, applied in the field of powder metallurgy, can solve the problems of easy agglomeration of second phase particles, low material strength and elastic modulus, and achieve simple equipment, high elastic modulus, and easy realization of parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for preparing an in-situ MgO dispersion-strengthened ultrafine-grained Al-Mg alloy, comprising the steps of:

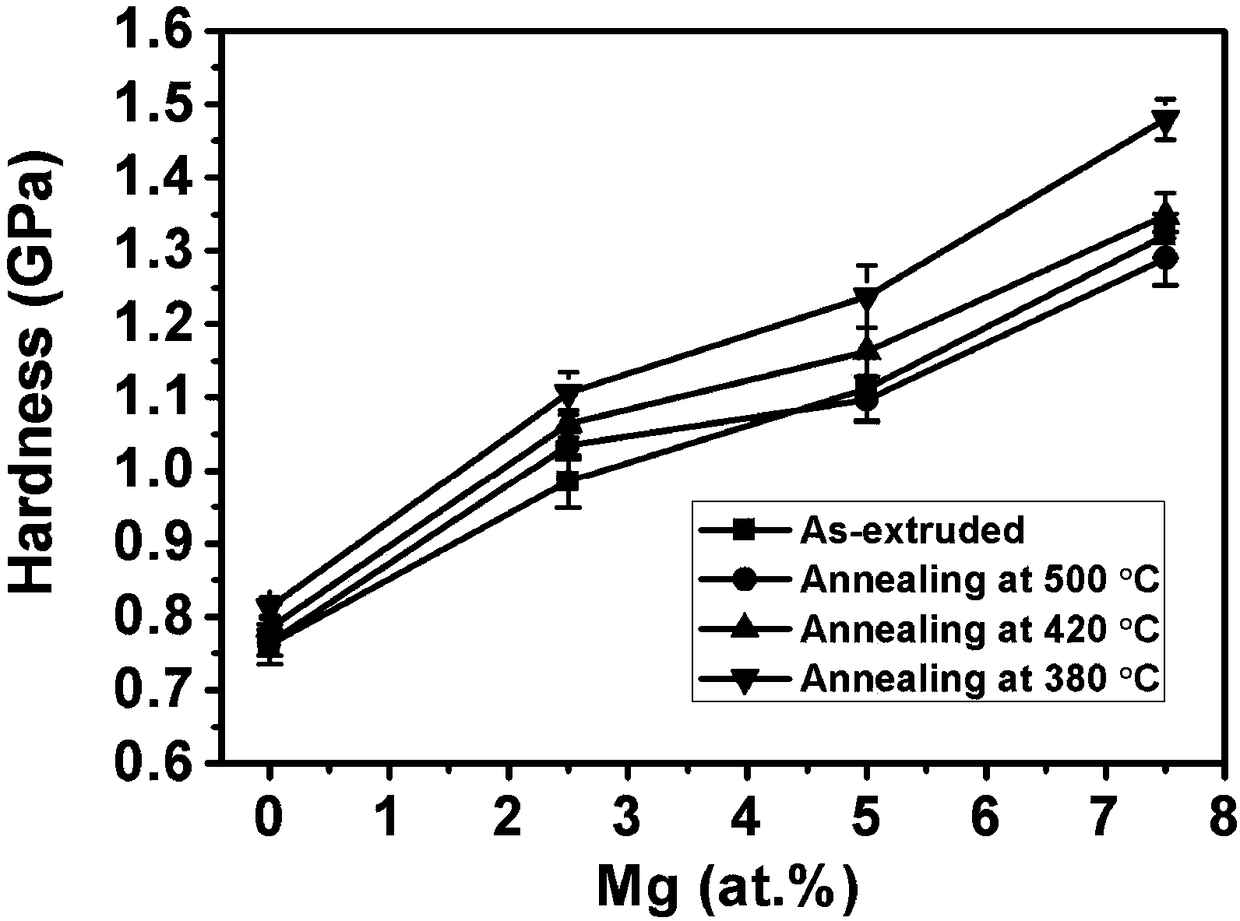

[0031] a. Weigh Al powder and Mg powder with a precision balance, wherein the atomic proportions of solute Mg atoms in the alloy are 0at.%, 2.5at.%, 5at.%, 7.5at.% respectively; select 1wt.% stearin Acid as a process control agent to prevent and avoid excessive cold welding of powder;

[0032] b. Put the weighed Al powder and Mg powder into the ball mill jar equipped with stainless steel grinding balls respectively, and the stainless steel grinding balls are 5 steel balls with a diameter of 20mm and 10 steel balls with a diameter of 16mm; wherein, the Al powder and the Mg powder The ratio of the total mass of the powder to the total mass of the stainless steel grinding balls is 5:1;

[0033] c. In a glove box full of argon, seal the ball mill tank with stainless steel balls and powder;

[0034] d. First use a planetary ball mill to fully mix the powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com