Patents

Literature

35results about How to "Suitable for large-scale production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meningococcus capsular polysaccharide polyvalent multivalent conjugate vaccine, preparation method and application thereof

InactiveCN102078604AHigh yieldHigh purityNitro compound active ingredientsCarrier-bound antigen/hapten ingredientsFlocculationConjugate vaccine

The invention discloses a meningococcus capsular polysaccharide polyvalent multivalent conjugate vaccine, a preparation method and application thereof. The polyvalent multivalent conjugate vaccine comprises at least two conjugates of group A, group C, group Y or Group W135 meningococcus capsular polysaccharide and cholera toxin B-subunit. The invention improves the method for extracting the meningococcus capsular polysaccharide, and improves the yield and purity of the capsular polysaccharide by adopting a flocculation extraction method under an electric field.

Owner:BEIJING MINHAI BIOTECH +1

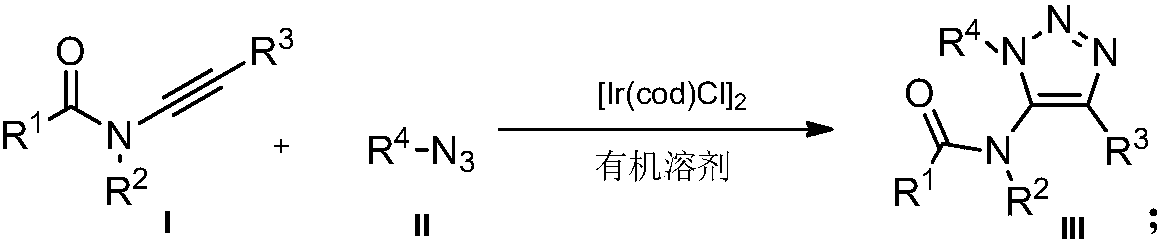

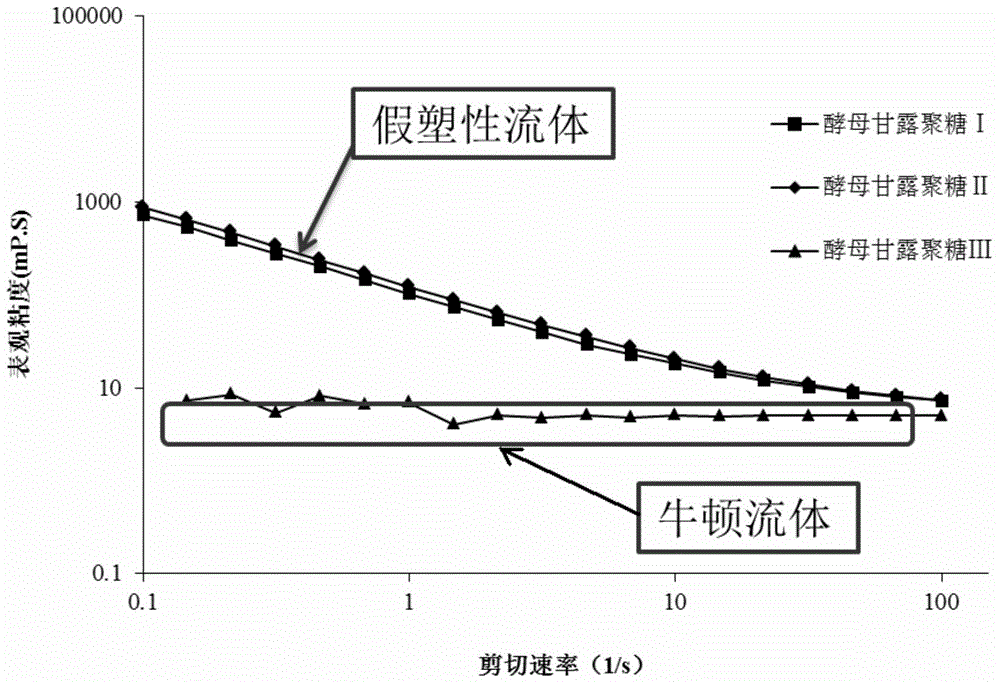

Preparation method of novel 5-acylamino-1,4,5-trisubstituted 1,2,3-triazole

InactiveCN107721984AMild reaction conditionsReaction conditions greenOrganic chemistryOrganic solventOrganic synthesis

The invention belongs to the technical field of organic synthesis, and relates to a preparation method of novel 5-acylamino-1,4,5-trisubstituted 1,2,3-triazole. The novel 5-acylamino-1,4,5-trisubstituted 1,2,3-triazole is prepared by catalyzing a ynamine compound and nitrine in an organic solvent and under the action of a catalyst of 1,5-cyclooctadiene iridium chloride dipolymer ([Ir(COD)Cl]2). The preparation method of a 5-acylamino-1,4,5-trisubstituted 1,2,3-triazole product is mild in reaction conditions, and the yield of the product is not lower than 70 percent; the preparation method is mild in reaction conditions, is green and is high in reaction efficiency and is more suitable for large-scale production requirements, and a prepared novel 5-acylamino-1,4,5-trisubstituted 1,2,3-triazole compound has potential physiological activity.

Owner:DALIAN UNIV OF TECH

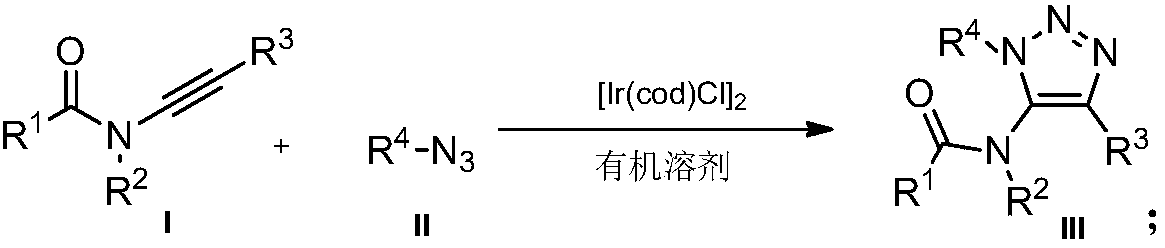

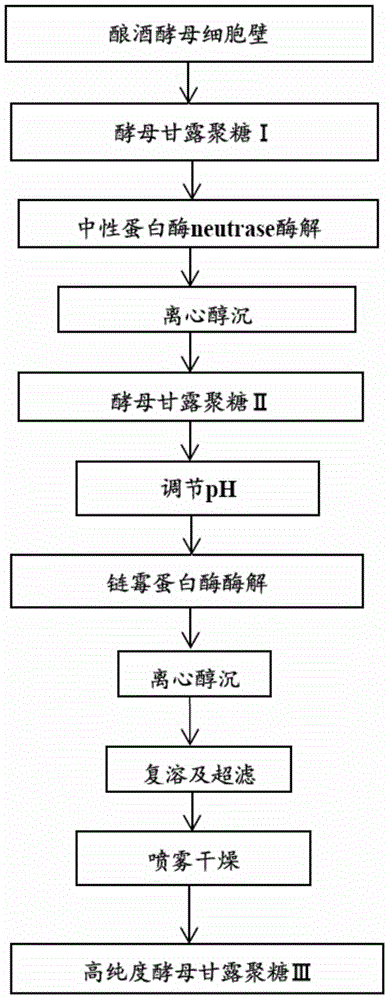

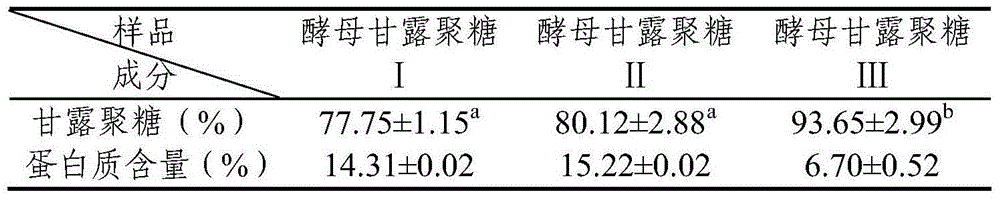

Preparation method of low-viscosity and high-purity yeast mannan

The invention provides a preparation method of low-viscosity and high-purity yeast mannan. The preparation method comprises the following steps: taking the cell wall of saccharomyces cerevisiae as a raw material, adopting water extract and alcohol precipitation method to obtain rough yeast mannan, performing enzymolysis and centrifugation on the rough yeast mannan by neutral protease and pronase, and processing to obtain the product. The preparation method combines secondary digestion, centrifugation, ultrafiltration with spray drying technology, the equipment adopted can meet the requirements of the industrialized production, the yeast mannan obtained has a purity greater than 90 percent, is low in viscosity, belongs to Newtonian fluid, and cannot affect the rheological property of system in actual application.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

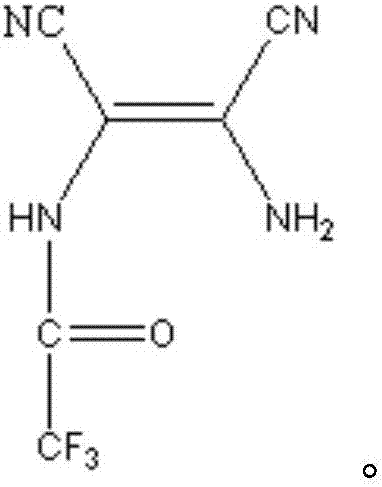

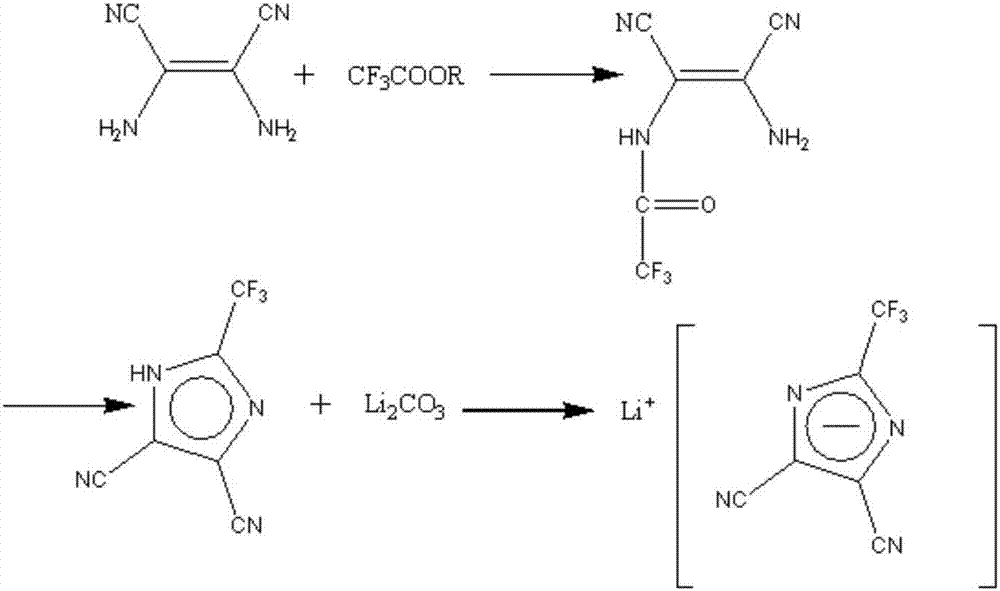

4,5-dicyano-2-trifluoromethylimidazole, its preparation intermediate and preparation method of its salt

ActiveCN106008262BHigh purityStrong irritantCarboxylic acid nitrile preparationOrganic compound preparationChemical synthesisEvaporation

The invention belongs to the technical field of chemical synthesis and particularly relates to a preparation method of 4,5-dicyan base-2-trifluoro-methylimidazole and a prepared intermediate and salt thereof. Diaminoaleo dinitrile and trifluoroacetic acid ester are subjected to aminolysis of ester with solvent or without solvent, amide is obtained, the amide is then subjected to intramolecular dehydration, a crude product of the 4,5-dicyan base-2-trifluoro-methylimidazole is obtained, after the crude product is purified, high-purity dehydrate of the 4,5-dicyan base-2-trifluoro-methylimidazole is obtained, then the high-purity dehydrate is mixed with water phase suspension liquid of salt of metal elements and stirred for a reaction, after the reaction is ended, filtering is conducted to remove an undissolved substance, filtrate is evaporated to be dry in a rotary evaporation mode, after dissolution with solvent is conducted again, filtering, rotary evaporation and vacuum drying are conducted, and the high-purity 4,5-dicyan base-2-trifluoro-methylimidazole salt is obtained. The condition of the whole technological process is safer and milder compared with those of other processes for producing the 4,5-dicyan base-2-trifluoro-methylimidazole, and the preparation method meets the requirement for scaled production.

Owner:武汉海斯普林科技发展有限公司

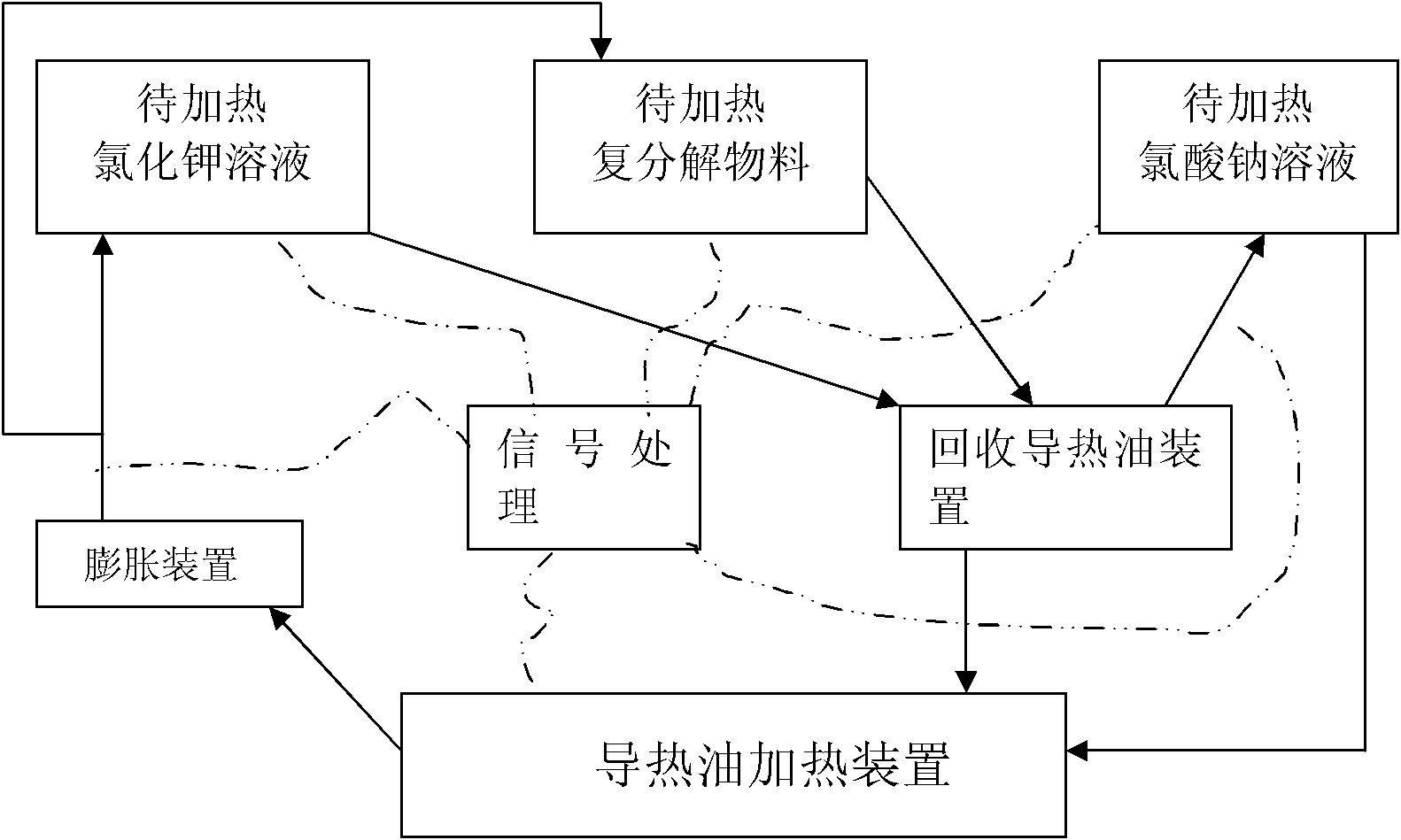

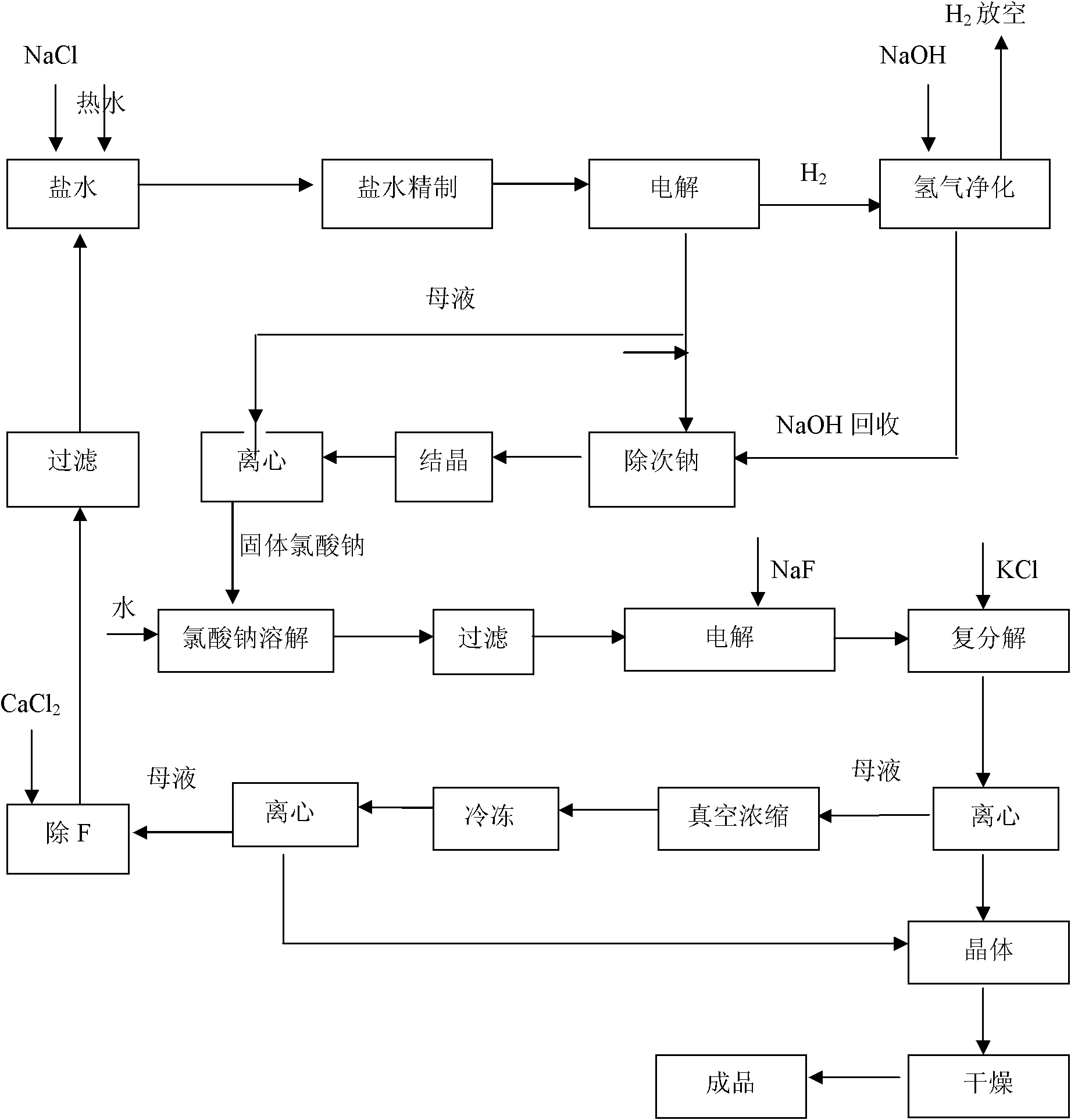

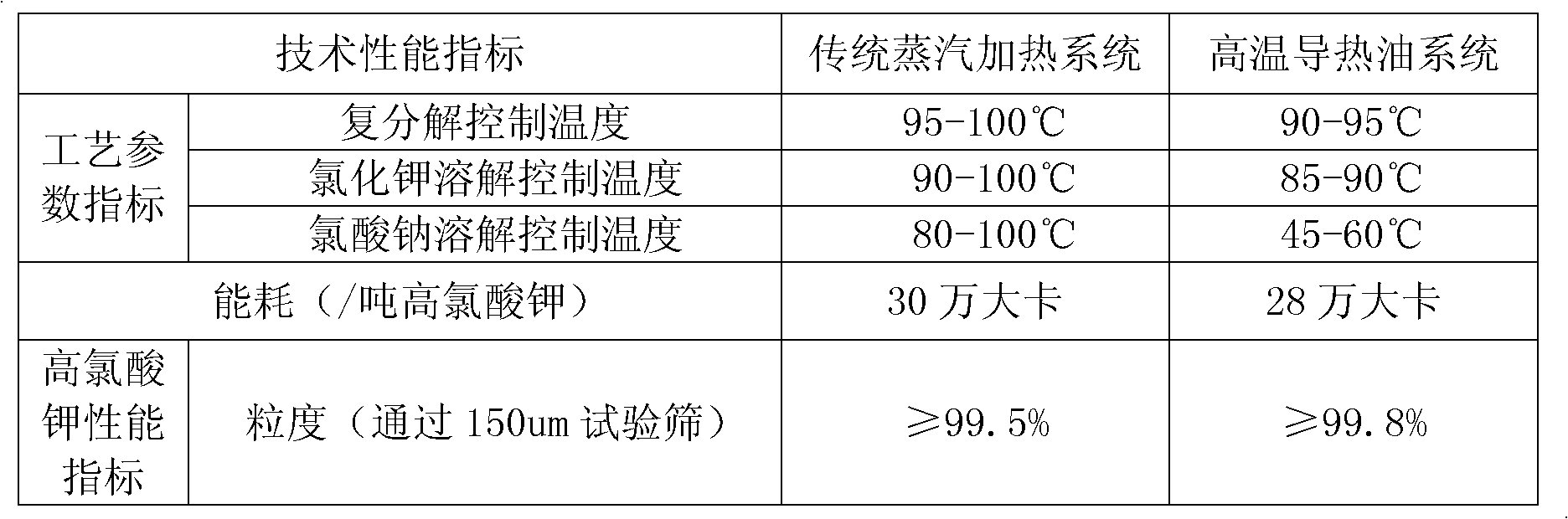

Comprehensive utilization method of heat energy in potassium perchlorate production process

InactiveCN101962174AAbundant power resourcesLow electricity priceElectrolysis componentsPerchloratesThermal energyHeat conducting

The invention relates to a comprehensive utilization method of heat energy in a potassium perchlorate production process, which belongs to the technical field of potassium perchlorate production. The invention aims to solve the technical problem of providing a new heat supplying method for the technical field of potassium perchlorate production, increases energy utilization efficiency and solves environmental pressure caused by the three wastes generated by the coal consumption of a boiler. The invention has the technical schemes of: heating by adopting high-temperature heat conducting oil, in particular to a conduction process that after the heat conducting oil is heated, transmitting heat to materials which need to be heated to cause that the temperature of the heat conducting oil is reduced, and repeatedly heating. The comprehensive utilization method increases energy utilization efficiency and reduces the environmental pressure caused by the three wastes generated by the coal consumption of a boiler, and otherwise, the comprehensive utilization method increases continuous production capacity, is suitable for large-scale production requirements and breaks the tradition that a perchloric acid double-decomposition process is only heated by steam in a long period.

Owner:茂县鑫盐化工有限公司

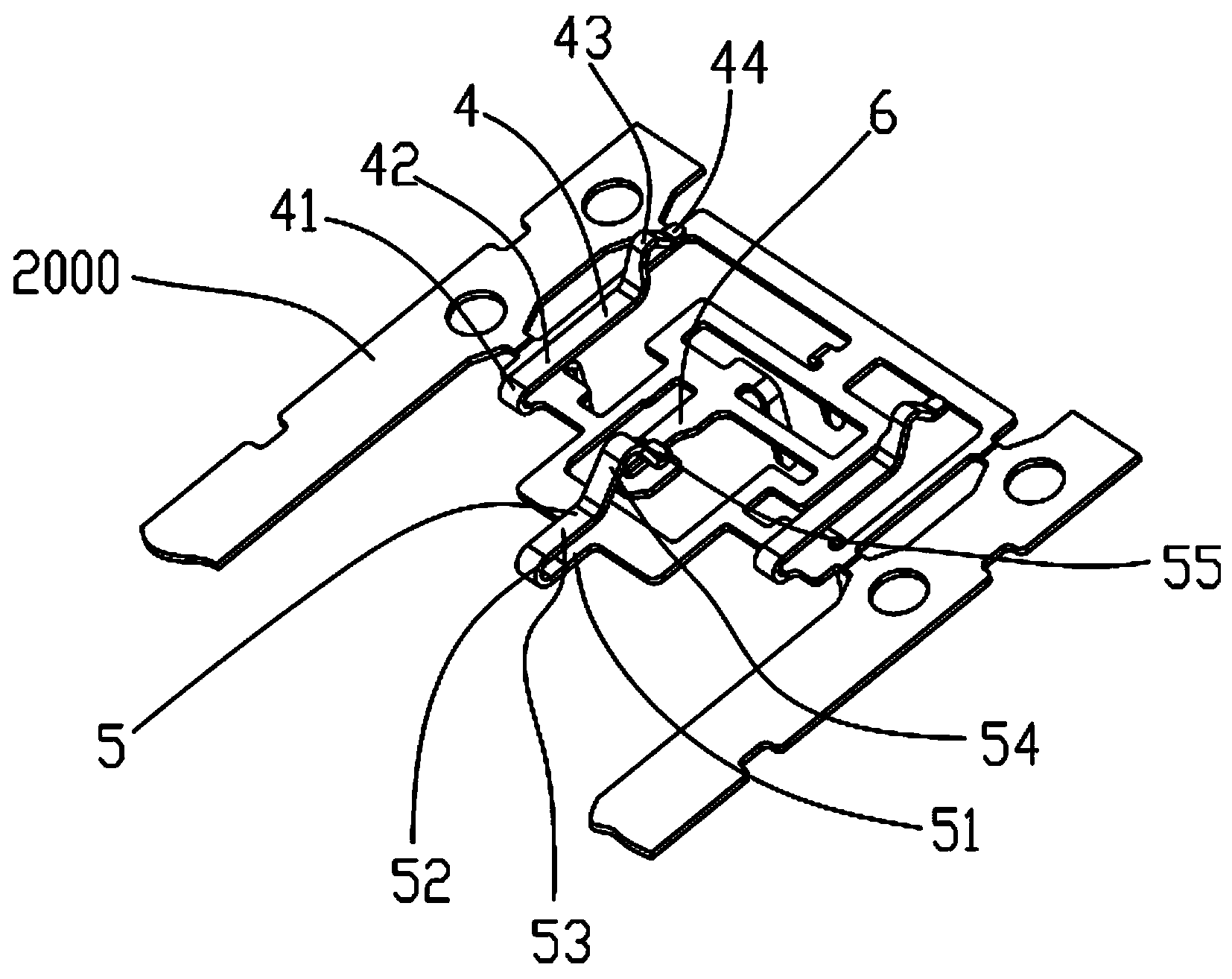

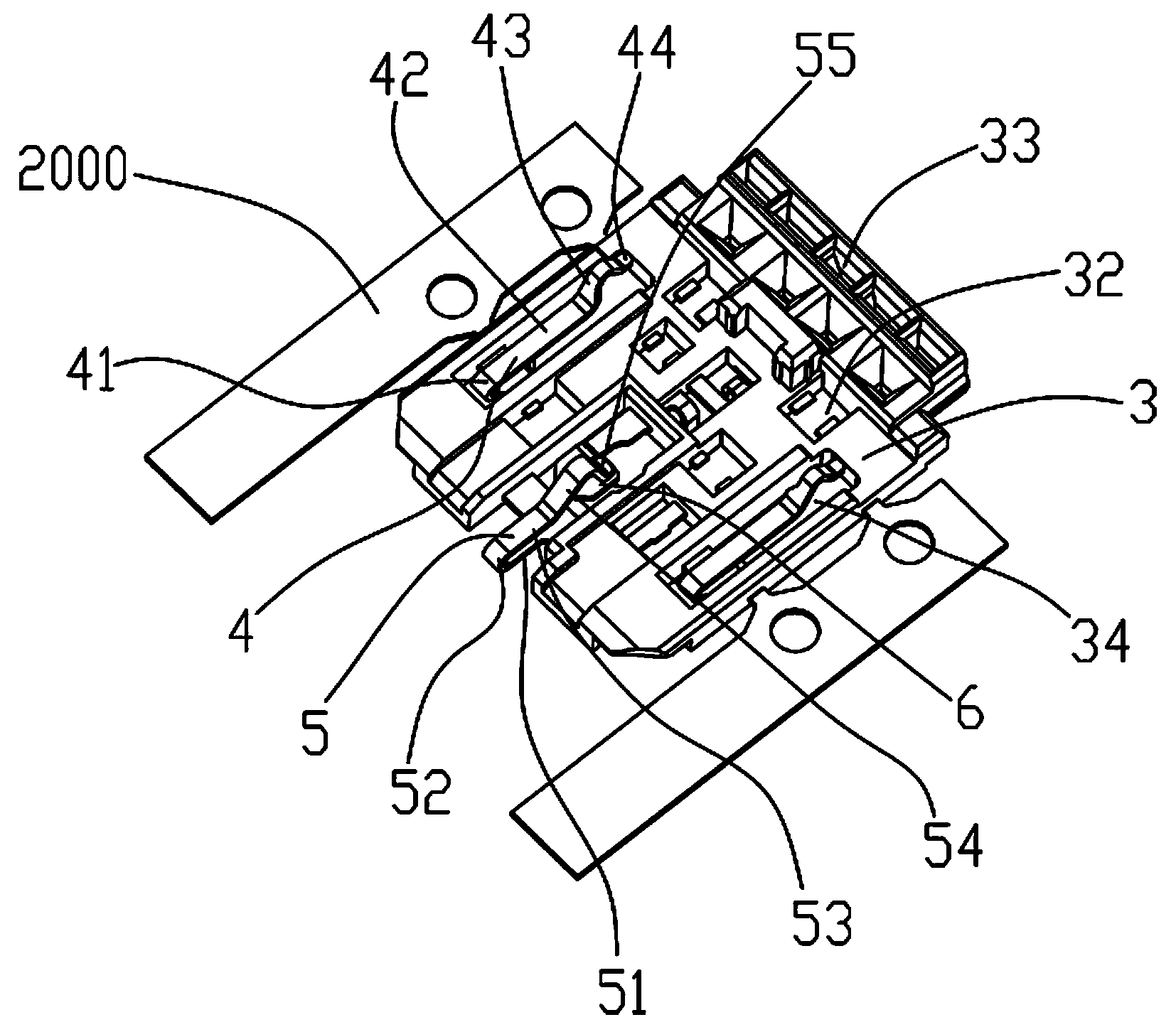

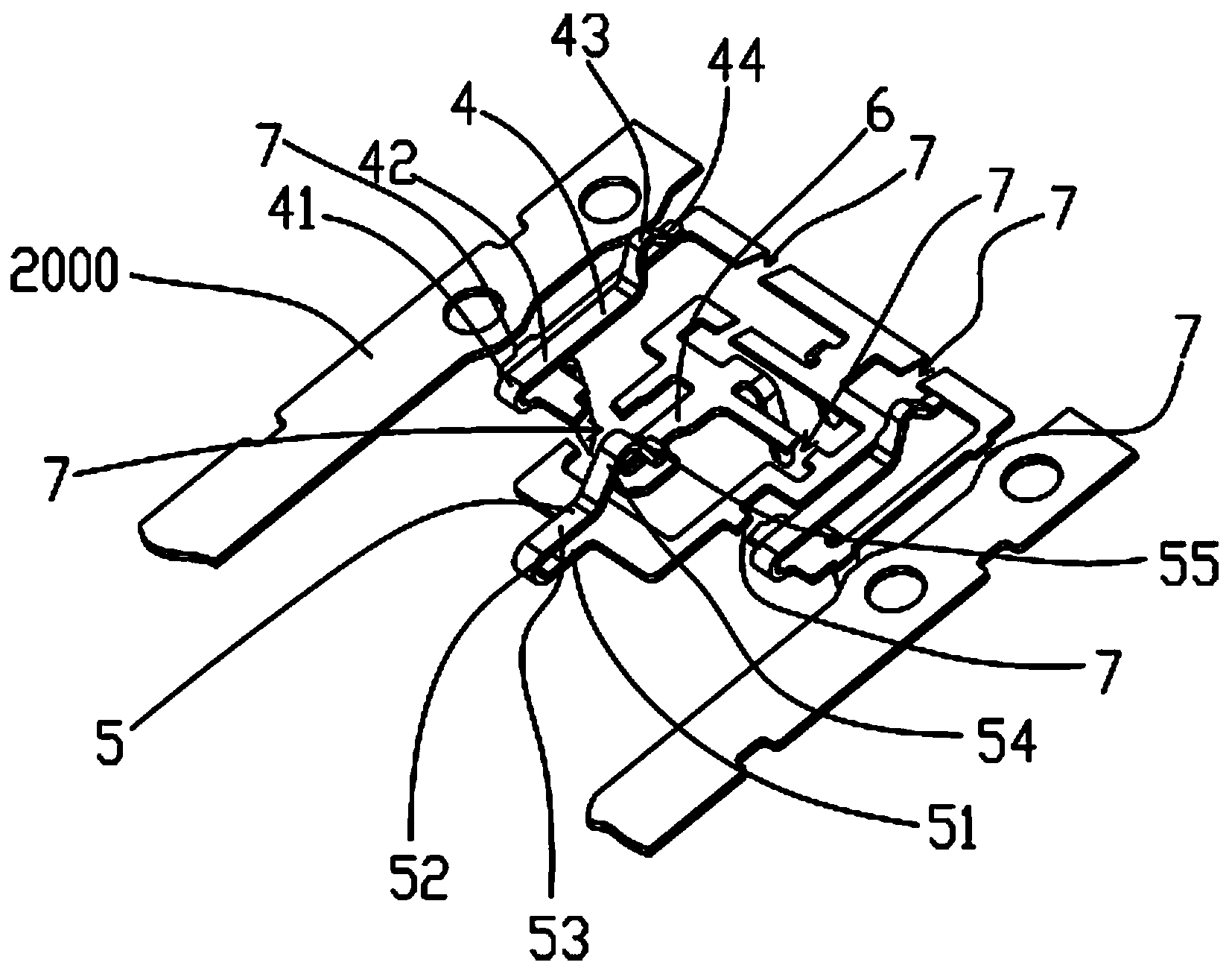

I/O connector with detection function and manufacturing method thereof

InactiveCN103840349AShorten production timeReduce manufacturing costContact member assembly/disassemblyIncorrect coupling preventionStructural engineeringMechanical engineering

Owner:BIZCONN INT CORP (SHEN ZHEN)

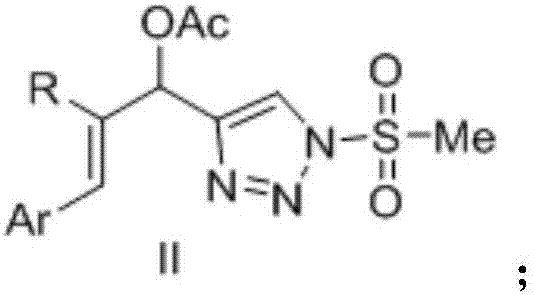

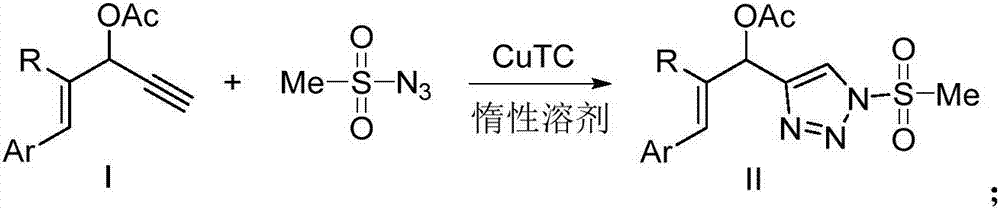

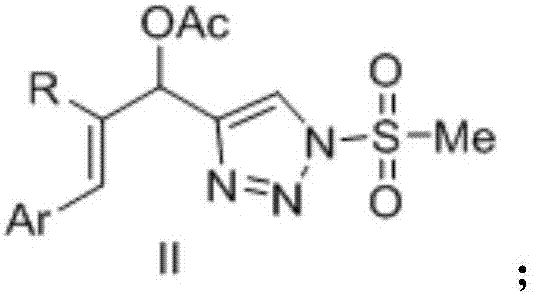

Novel 4-allyl acetate substituted N-sulfonyl 1,2,3-triazole and preparation method thereof

InactiveCN106966994AMild reaction conditionsSuitable for large-scale production requirementsOrganic chemistryArylAllyl acetate

The invention belongs to the technical field of organic synthesizing and provides novel 4-allyl acetate substituted N-sulfonyl 1,2,3-triazole and a preparation method thereof. The preparation method includes: in an inert solvent and under the action of a thiophene-2-copper formate catalyst, catalyzing (E)-1-aryl-1,4-eneyne-3-acetate compounds and sulfonyl azide to prepare the 4-allyl acetate substituted N-sulfonyl 1,2,3-triazole. The preparation method has the advantages that the method is mild in reaction condition, green, high in reaction efficiency and capable of satisfying large-scale production requirements, product yield is not lower than 70%, and the prepared 4-allyl acetate substituted N-sulfonyl 1,2,3-triazole has potent physiological activity.

Owner:DALIAN UNIV OF TECH

Method for preparing aluminum bronze and steel bimetallic material

The invention discloses a method for preparing an aluminum bronze and steel bimetallic material, wherein the method comprises the following specific steps that: aluminum bronze powder is subjected to acid cleaning treatment; the silicon bronze powder with silicon content being 1-5% is added into the treated aluminum bronze powder, and the mixture is subjected to ball milling so as to be uniformlyblended; the above uniformly blended powder is tiled on an electro-coppering surface of a steel plate; the steel plate with tiled powder is subjected to primary sintering; then the steel plate is subjected to secondary sintering after cold rolling. The test shows that the relative density of aluminum bronze in the aluminum bronze and steel bimetallic material can reach 99.5%, and the interface bonding strength is more than 85 MPa; in addition, the method has the advantages of low equipment investment, higher rate of finished products, simplicity in operation and lower production cost and the like, thereby meeting the requirement of large-scale production; and the method has industrial application value.

Owner:SHANGHAI UNIV OF ENG SCI +1

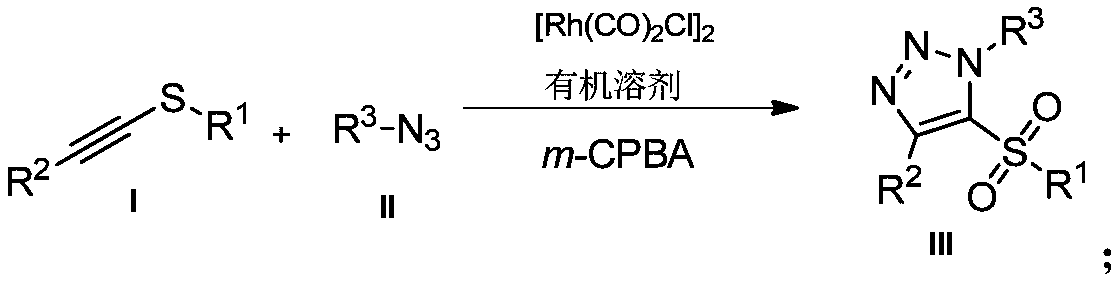

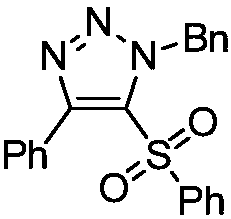

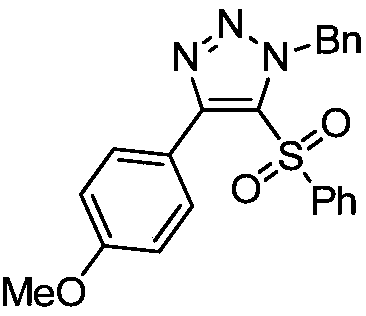

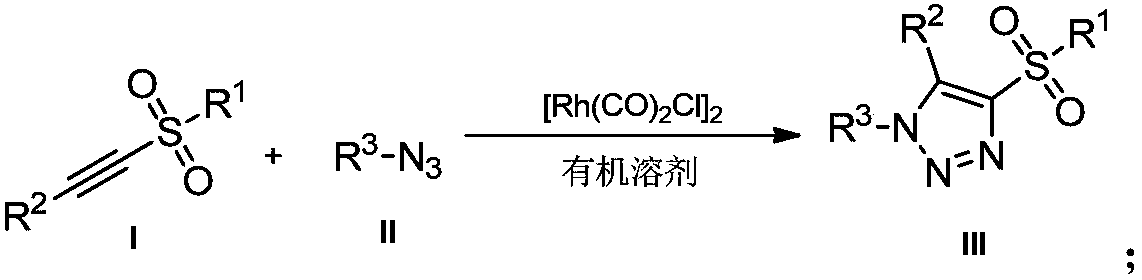

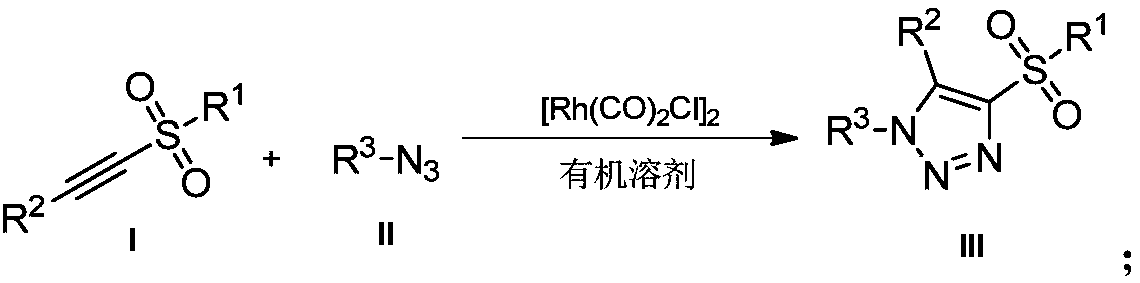

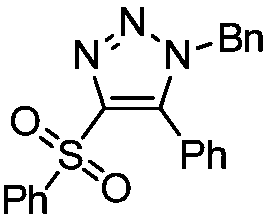

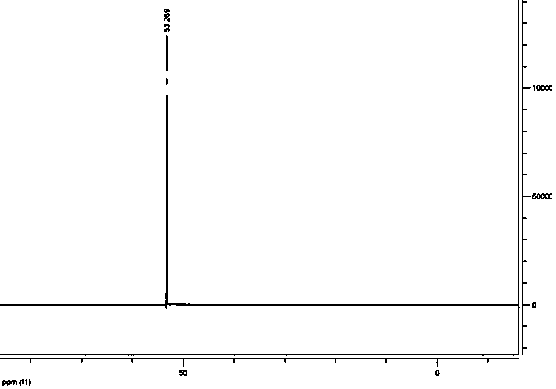

Novel preparation method of 5-sulfonyl-1,4,5-trisubstituted 1,2,3-triazole

InactiveCN109232449AMild reaction conditionsReaction conditions greenOrganic chemistryOrganic solvent3-chloroperoxybenzoic acid

The invention belongs to the technical field of organic synthesis and provides a novel preparation method of 5-sulfonyl-1,4,5-trisubstituted 1,2,3-triazole. The novel preparation method comprises thesteps: catalyzing a thioethyne compound to react with azide in an organic solvent under the action of a rhodium carbonyl chloride dimer catalyst; then, adding 3-chloroperoxybenzoic acid; and preparing5-sulfonyl-1,4,5-trisubstituted 1,2,3-triazole by using a 'one-pot method'. The preparation method of 5-sulfonyl-1,4,5-trisubstituted 1,2,3-triazole is mild in reaction condition and the yield of notlower than 55%. The preparation method is mild in reaction condition, green, high in reaction efficiency and more meets the requirement for large-scale production, and the prepared 5-sulfonyl-1,4,5-trisubstituted 1,2,3-triazole compound has potential physiological activity.

Owner:DALIAN UNIV OF TECH

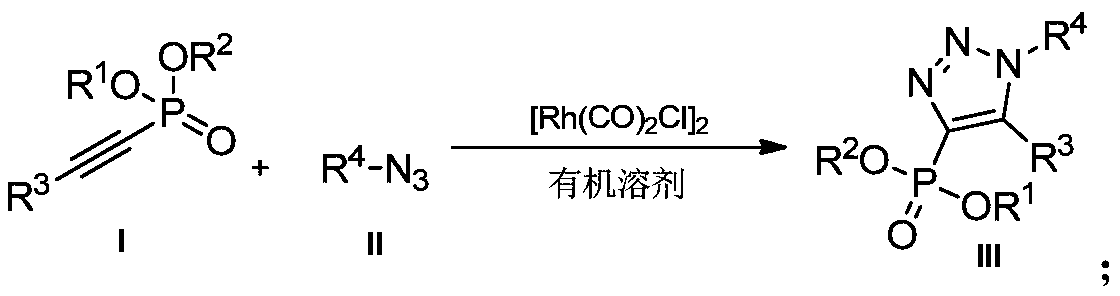

Novel method for preparing 4-sulfonyl-1,4,5-tri-substituted 1,2,3-triazole

InactiveCN109096214AMild reaction conditionsReaction conditions greenOrganic chemistryOrganic solventOrganic synthesis

The invention belongs to the technical field of organic synthesis and provides a novel method for preparing 4-sulfonyl-1,4,5-tri-substituted 1,2,3-triazole. The novel method comprises the following step: in an organic solvent, under the action of a tetracarbonyl rhodium chloride dimer catalyst, catalyzing a hydrocarbon compound in sulfonyl and nitrine, thereby obtaining the 4-sulfonyl-1,4,5-tri-substituted 1,2,3-triazole. The method for preparing the 4-sulfonyl-1,4,5-tri-substituted 1,2,3-triazole, which is provided by the invention, is gentle in reaction condition and has a product yield which is not less than 70%. The method is gentle and green in reaction condition, high in reaction efficiency and applicable to on-scale production requirements, and the prepared 4-sulfonyl-1,4,5-tri-substituted 1,2,3-triazole compound has potential physiological activity.

Owner:DALIAN UNIV OF TECH

High-purity difluorosulfonylimide preparation method

The invention discloses a high-purity difluorosulfonylimide preparation method, which comprises: 1, adding a protic solution accounting for 0.1-10% of the mass of a difluorosulfonylimide crude productto the difluorosulfonylimide crude product, carrying out a thermal insulation reaction for 10 min-10 h at a temperature of 10-120 DEG C, and slowly introducing HF gas accounting for 0-10% of the massof the difluorosulfonylimide crude product during the thermal insulation; and 2, distilling the difluorosulfonylimide obtained in the step 1 to obtain the high-purity difluorosulfonylimide with a chlorine ion content of less than 20 ppm. Compared with the conventional direct distillation and rectification schemes, the method of the present invention has the following characteristics that the chemical treatment method of selective decomposition is adopted, the physical separation is supplemented, and the difference in the boiling points of each substance in the system after the treatment is high, such that the separation effect of the scheme is significant, the impurity chlorine ion content in the product difluorosulfonylimide can be reduced to less than 20 ppm, and the raw material purityrequirements in the preparation of lithium bis(fluorosulfonyl)imide for subsequent electrolytic solutions can be met.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

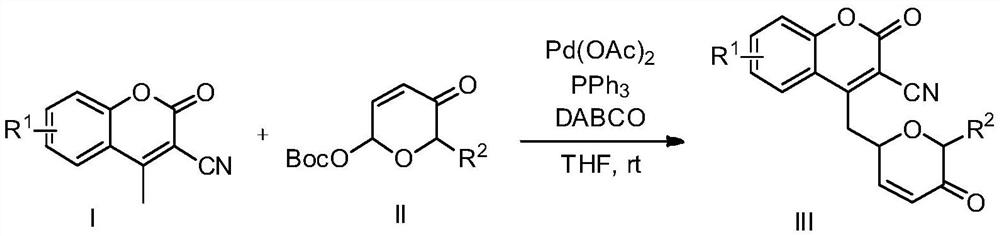

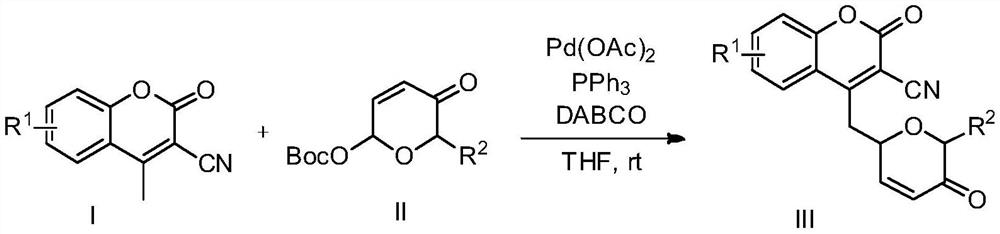

Preparation method of novel dihydropyrone coumarin compound

InactiveCN112409345AMild reaction conditionsHigh regional selectivityOrganic chemistryOrganic synthesisCatalytic effect

The invention belongs to the technical field of organic synthesis, and relates to a preparation method of a novel dihydropyrone coumarin compound. The preparation method comprises the following steps:in tetrahydrofuran, takingtriphenyl phosphine as a ligand and1,4-diazabicyclo[2.2.2] octane as an alkali, and under the catalytic action of Pd(OAc)2, reacting a dihydropyrone compound with a 3-cyano-4-methyl coumarin compound to prepare the 3-cyano-4-(6-dihydropyrone) methyl coumarin. The preparation method is mild in reaction condition, and the product yield is not lower than 52%. The inventionprovides a preparation method for obtaining dihydropyrone coumarin with excellent regioselectivity and high stereoselectivity by a simple and effective method. The preparation method is mild in reaction condition, green, high in reaction efficiency and more suitable for large-scale production requirements, and the prepared dihydropyrone coumarin compound is a compound with potential physiologicalactivity.

Owner:DALIAN UNIV OF TECH

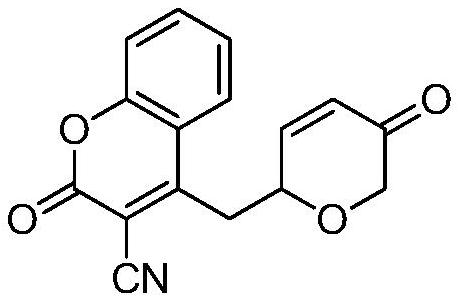

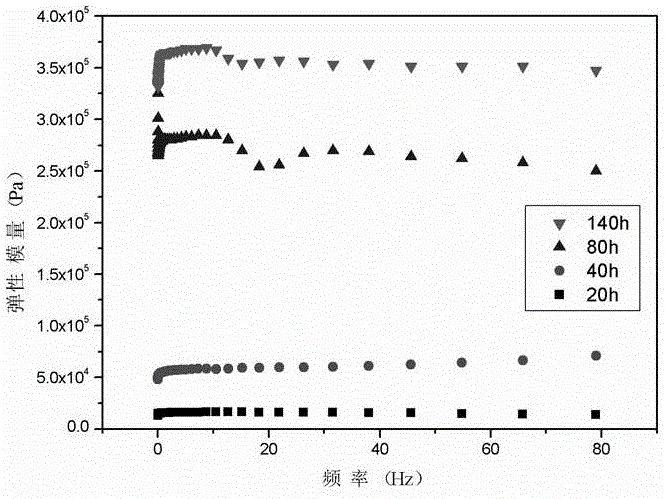

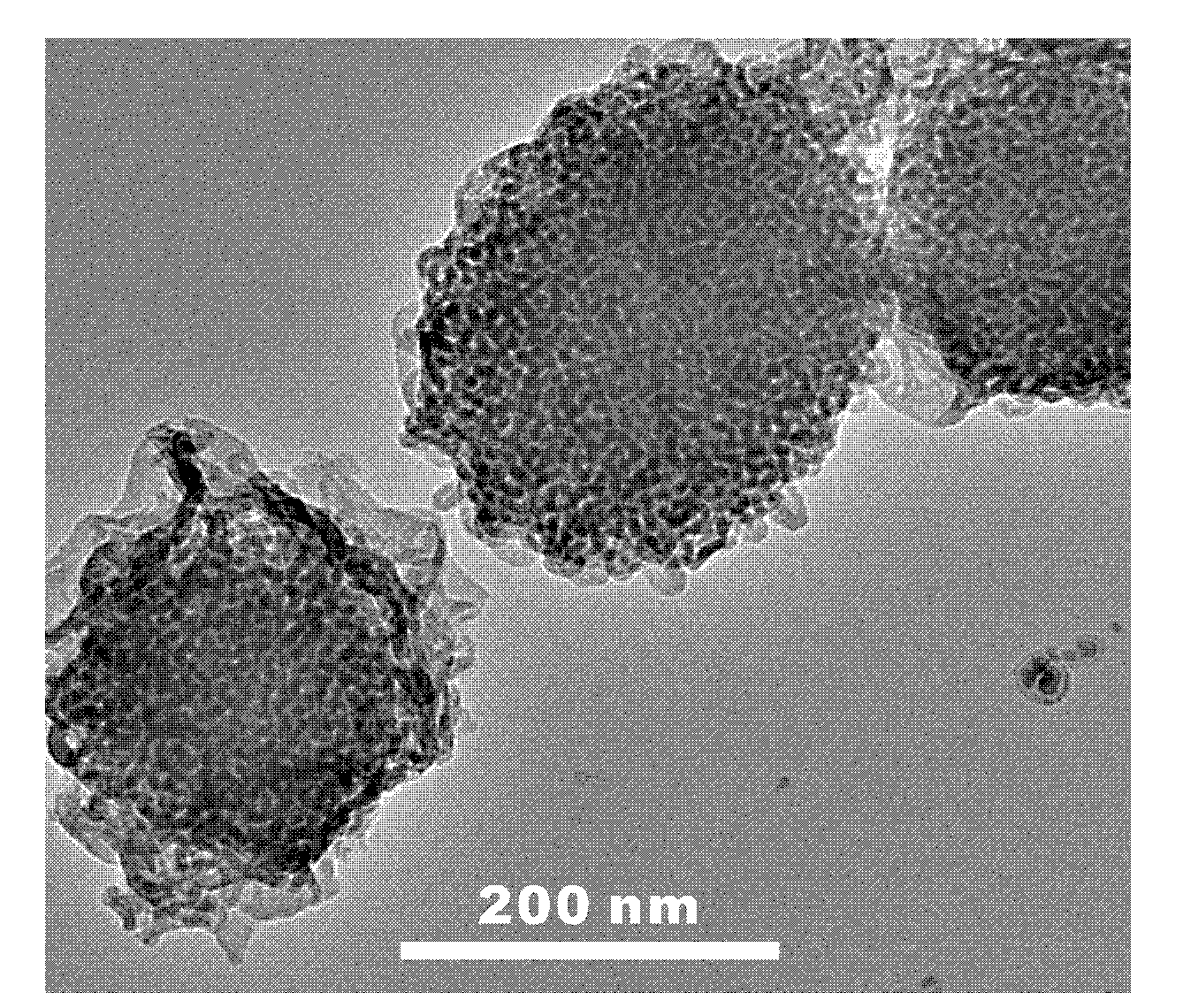

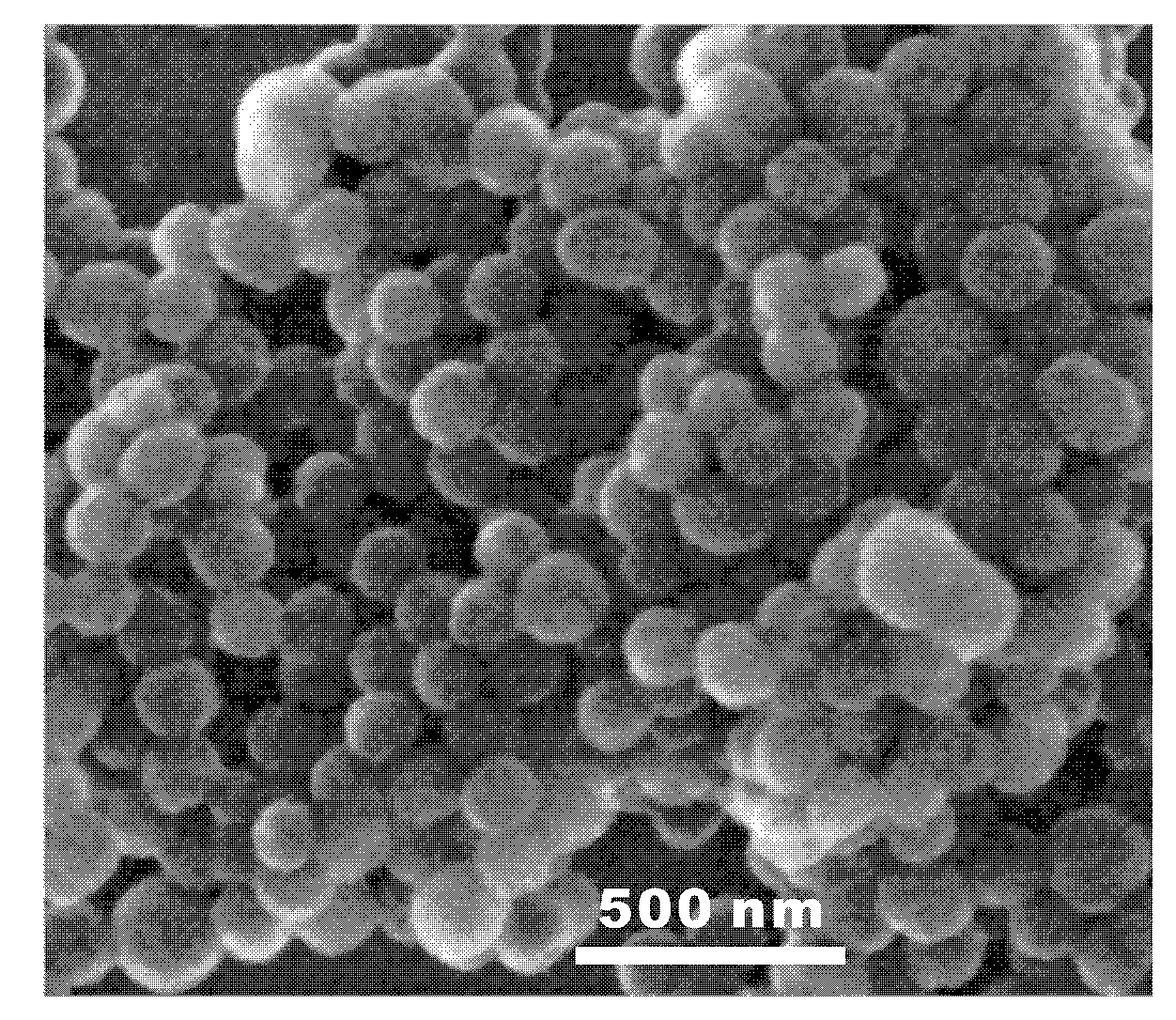

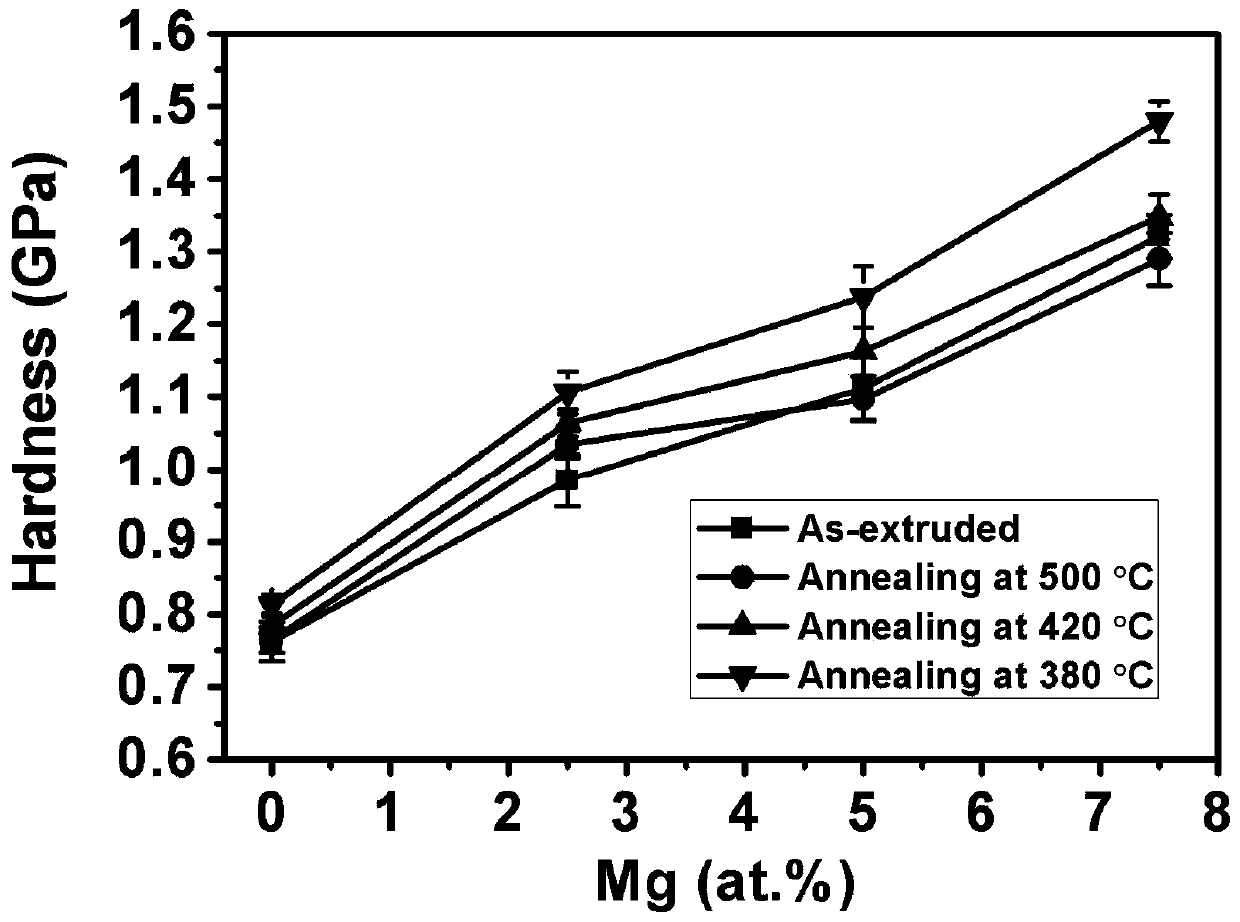

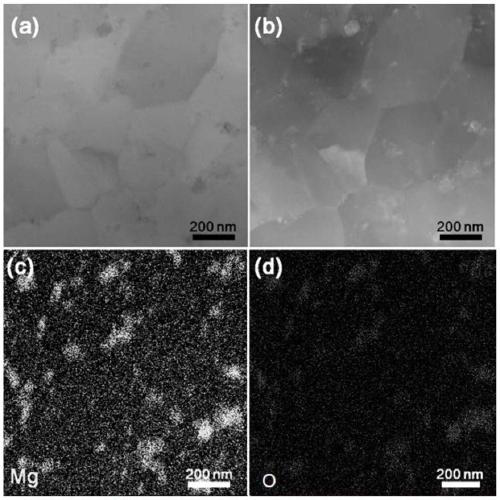

Preparation method for in-situ generation of MgO dispersion strengthened ultra-fine grain Al-Mg alloy

The invention belongs to the field of powder metallurgy, and particularly relates to a preparation method for in-situ generation of an MgO dispersion strengthened ultra-fine grain Al-Mg alloy. According to the technical scheme of the preparation method, the preparation method includes the following steps that Al powder and Mg powder are weighed, wherein solute Mg atoms account for 0-8 at.% of atoms of the alloy; ball-milling is performed, wherein firstly the powder is sufficiently mixed for 6 h through a planetary ball mill at a low running speed, and the rotating speed is 180-220 r / min; thenthe mixed powder is subjected to ball milling for 36 h at a high running speed, the rotating speed is 480-520 r / min, and no intermittence exists in the high-energy ball milling period; passivation treatment is performed, wherein pressing into powder blank is performed; heating to 500 DEG C is performed, then heat preserving under 500 DEG C is performed for 2 min, after heat preserving ends, the heated powder blank is immediately transferred into a preheated extruding die, and the powder blank is subjected to hot extruding to form a hot extruded rod with the diameter being 6 mm; and heat treatment is performed. The alloy prepared through the preparation method has the beneficial effects of being low in density, high in strength, high in elastic modulus, superfine in microscopic structure and clean in particle interface.

Owner:NORTHEASTERN UNIV

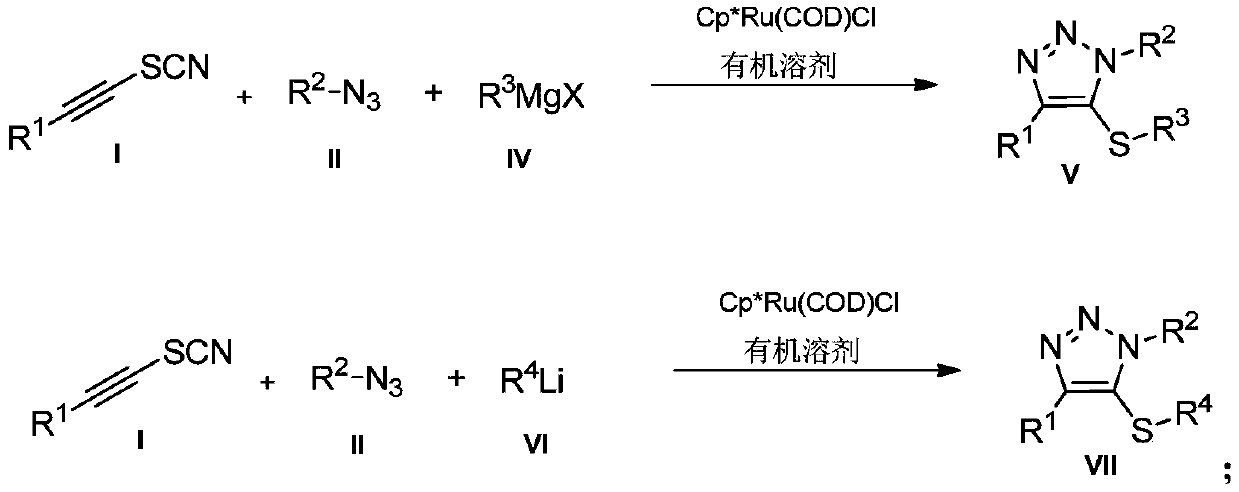

Preparation method and application of novel 5-thiocyanate substituted 1,4,5-trisubstituted 1,2,3-triazole

InactiveCN110590685AMild reaction conditionsReaction conditions greenOrganic chemistryOrganic synthesisThio-

The invention belongs to the technical field of organic synthesis, and provides a preparation method and application of a novel 5-thiocyanate substituted 1,4,5-trisubstituted 1,2,3-triazole. The preparation method of the 5-thiocyanate substituted 1,4,5-trisubstituted 1,2,3-triazole and a preparation method of 5-thio-1,4,5-trisubstituted 1,2,3-triazole have mild reaction conditions, and the productyields are not less than 62%. The preparation methods have the mild reaction conditions, are environmentally friendly and have high reaction efficiency, and the methods are more suitable for large-scale production requirements; and the prepared 5-thio-1,4,5-trisubstituted 1,2,3-triazole compound has potential physiological activity.

Owner:DALIAN UNIV OF TECH

Mixed liquor for labeling and labeling method for animals

InactiveCN101497779AReduce the injection doseStrong concealmentOther chemical processesClimate change adaptationSimple componentNon magnetic

The invention relates to mixture indicator and an animal indicating method, belongs to an indicating method, and provides mixture indicator and an animal indicating method adopting the mixture indicator. Raw materials of the mixture indicator comprise magnetic particle and edible oil, wherein the magnetic particle at least contains iron and carbon. The mixture indicator is injected into an object to be indicated, a detector determines whether the object is indicated or not, and the indicated object is replaced after the indication is completed. Because the raw materials of the mixture indicator have simple component, stable chemical property, easy obtaining of the raw materials, low cost and easy preparation, the injection quantity of the mixture indicator is little, the indicating speed is very high, and the indicating cost is very low. The invention not only influences the indicated object little, but also has higher safety to a human body, has wide range of application, especially the application to living microbe, such as the cultivation of bionts of rabbit fish, amphioxus, loach, bird, and the like, and can be also used as an indicator of a nonmagnetic product (the product without influencing magnetic lines).

Owner:罗士柱

A kind of preparation method of high-purity difluorosulfonimide

ActiveCN109264682BPurity requirements metEasy to separateNitrogen compoundsChemical treatmentIon content

The invention discloses a high-purity difluorosulfonylimide preparation method, which comprises: 1, adding a protic solution accounting for 0.1-10% of the mass of a difluorosulfonylimide crude productto the difluorosulfonylimide crude product, carrying out a thermal insulation reaction for 10 min-10 h at a temperature of 10-120 DEG C, and slowly introducing HF gas accounting for 0-10% of the massof the difluorosulfonylimide crude product during the thermal insulation; and 2, distilling the difluorosulfonylimide obtained in the step 1 to obtain the high-purity difluorosulfonylimide with a chlorine ion content of less than 20 ppm. Compared with the conventional direct distillation and rectification schemes, the method of the present invention has the following characteristics that the chemical treatment method of selective decomposition is adopted, the physical separation is supplemented, and the difference in the boiling points of each substance in the system after the treatment is high, such that the separation effect of the scheme is significant, the impurity chlorine ion content in the product difluorosulfonylimide can be reduced to less than 20 ppm, and the raw material purityrequirements in the preparation of lithium bis(fluorosulfonyl)imide for subsequent electrolytic solutions can be met.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

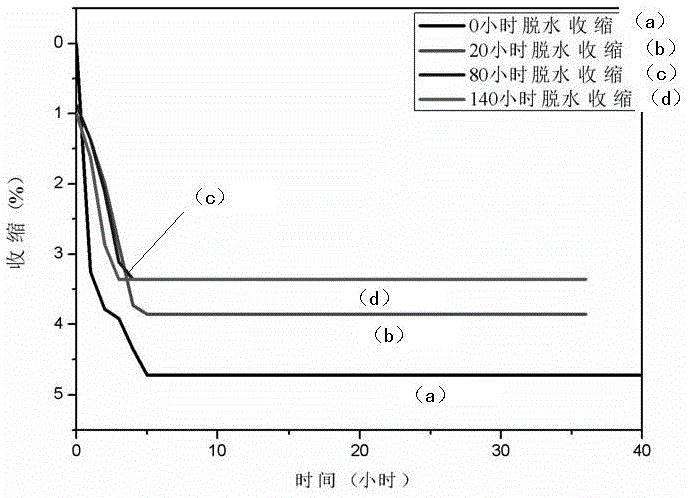

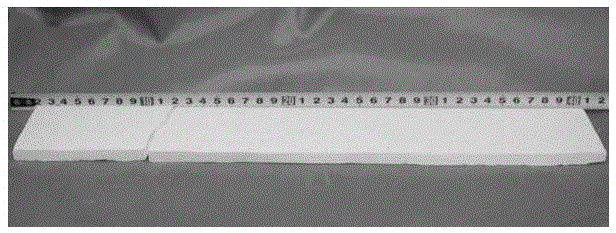

A kind of preparation method of large-scale ceramic biscuit

ActiveCN104085041BImprove mechanical propertiesIncrease the degree of cross-linkingCeramic shaping apparatusMetallurgySlurry

The invention provides a method for preparing a large-size ceramic biscuit. The method includes the steps that firstly, preprocessed ceramic slurry with uniformly scattered gel systems is injected into a forming die to undergo in-situ solidification to obtain ceramic biscuit gel, the forming die is sealed so that the ceramic biscuit gel can be desolventized at the temperature of 30-80 DEG C and shrinks for twenty hours, and after seven days, drying processing is carried out and the large-size ceramic biscuit is obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

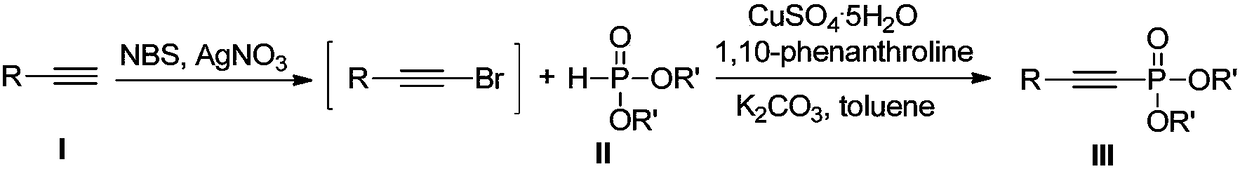

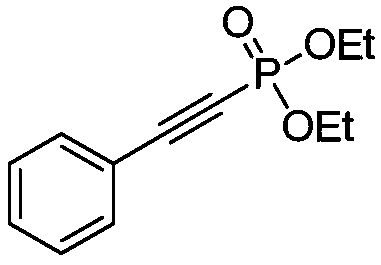

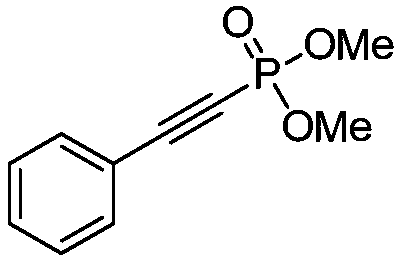

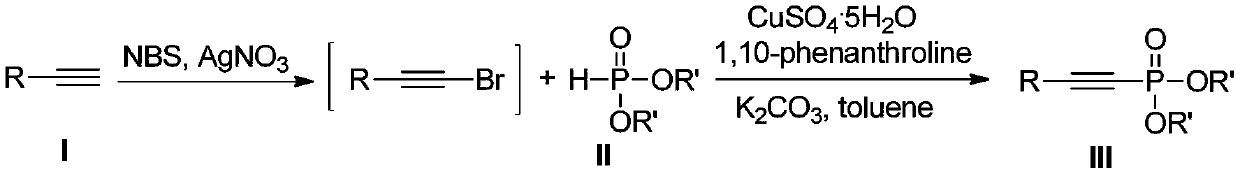

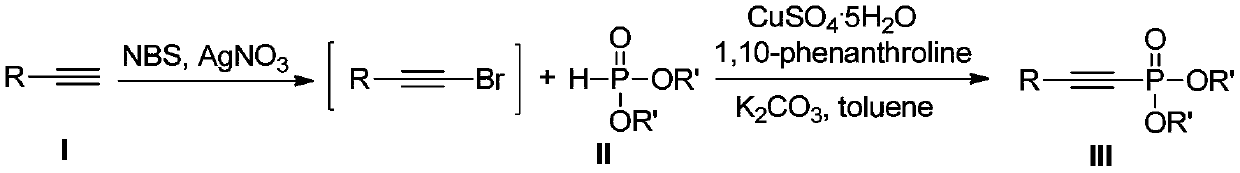

Method for preparing novel alkynyl phosphate

ActiveCN109180725ASimple reaction conditionsImprove reaction efficiencyGroup 5/15 element organic compoundsChemistryOrganic synthesis

The invention belongs to the technical field of organic synthesis, and provides a method for preparing novel alkynyl phosphate. The method comprises the following steps: in an organic solvent, under the action of a silver nitrate catalyst, using 1.2 equivalent amount of N-bromo-succinimide as a brominating agent, under room temperature condition, performing in-situ formation of an alkynyl bromide,adding copper sulfate pentahydrate as a catalyst, taking 1,10-phenanthroline as a ligand, reacting 2 equivalent amount of potash in toluene at the temperature of 65 DEG C for 12-24 hours, and obtaining the alkynyl phosphate compounds with the yield being 75%-86%. The method prepares the alkynyl phosphate compound, and the product yield is not less than 75%. The preparation method has simple reaction conditions and high reaction efficiency, and is more suitable for large-scale production requirements, and the prepared alkynyl phosphate compound has potential physiological activity and can be converted into various heterocyclic compounds.

Owner:DALIAN UNIV OF TECH

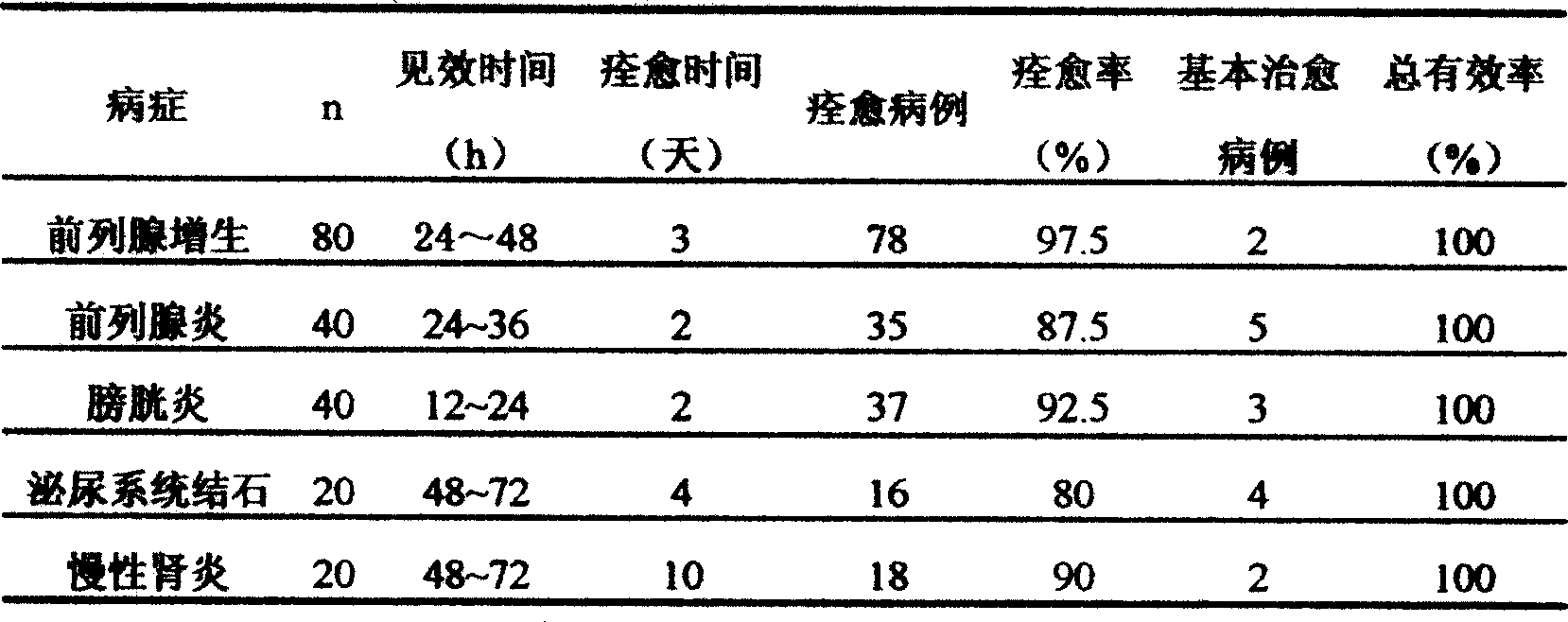

Chinese-medicinal preparation for treating urinary system disease

InactiveCN100462094CWide variety of sourcesLow costPowder deliveryAnthropod material medical ingredientsDiseaseCurative effect

A Chinese medicine for treating prostatoplasia, prostatitis, cystitis, calculosis in urinary system, chronic nephritis, urinary retention, etc is prepared from mole cricket and imperata rhizome.

Owner:彭新国

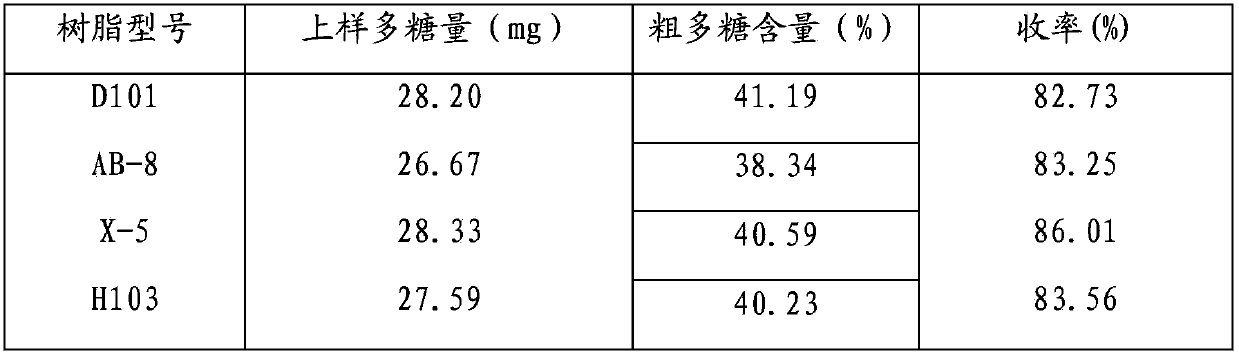

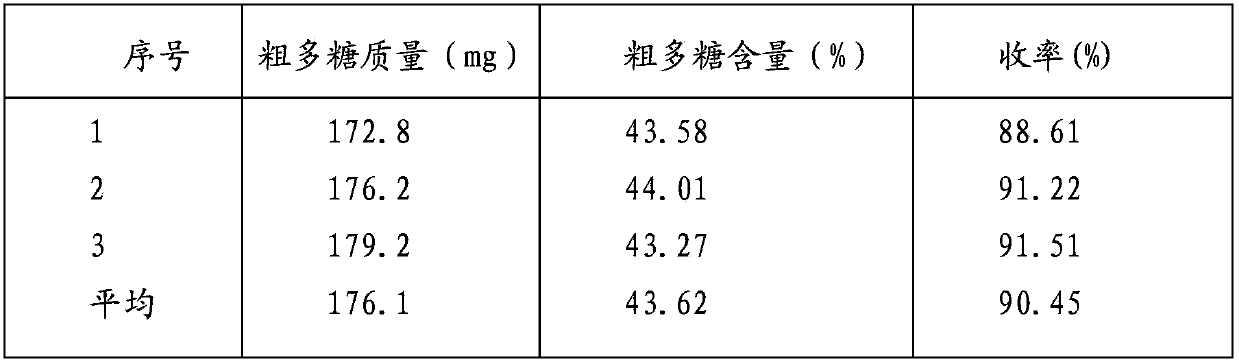

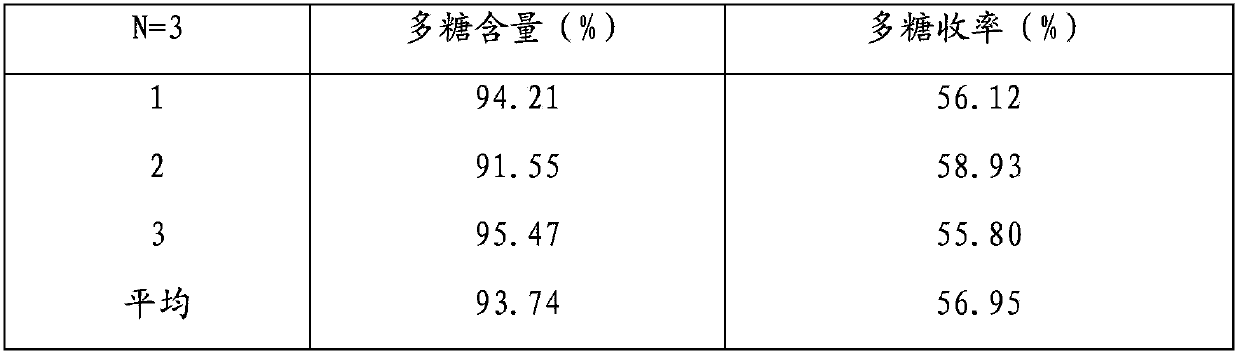

Method for preparing high-purity agaricus blazei murrill polysaccharide

InactiveCN102838686BImprove extraction efficiencyReduce extraction timeFood preparationPectinaseUltrafiltration

The invention discloses a method for preparing a high-purity agaricus blazei murrill polysaccharide and provides a method capable of obtaining high content of the agaricus blazei murrill polysaccharide and suitable for large-scale production. The method comprises the following steps of: adding cellulase and pectinase to an agaricus blazei murrill powder; after adding water to the agaricus blazei murrill powder and uniformly stirring the water and the agaricus blazei murrill powder, regulating the pH value of a mixture to 6.0+ / -0.1; performing enzymolysis on the mixture for 40 minutes; carrying out microwave extraction on the mixture; freezing and drying agaricus blazei murrill water extract so as to obtain a concentrated product; carrying out decolorizing and primary impurity removal treatment on an agaricus blazei murrill polysaccharide extract solution by using a macroporous adsorbing resin; and then carrying out deproteinization treatment on the agaricus blazei murrill polysaccharide extract solution by using an ion exchange resin; further purifying the agaricus blazei murrill polysaccharide after deproteinization by using an ultrafiltration technology, so as to eliminate micromolecular water soluble substances; pre-freezing an agaricus blazei murrill polysaccharide ultrafiltrate to -60 DEG C; maintaining the agaricus blazei murrill polysaccharide ultrafiltrate at -60 DEG C for at least 4 hours; and drying the agaricus blazei murrill polysaccharide ultrafiltrate at -45 DEG C in a vacuum state so as to obtain the agaricus blazei murrill polysaccharide. Through the adoption of a microwave synergistic complex enzyme method, a resin deproteinization technology, an ultrafiltration process purification and freeze-drying technology, which are combined with each other, the purity of the agaricus blazei murrill polysaccharide reaches 90%.

Owner:TIANJIN UNIV OF COMMERCE +1

Labeling method for globefish trace amount

InactiveCN101703021ASimple compositionChemically stableClimate change adaptationPisciculture and aquariaIron powderUltra fine

The invention discloses a labeling liquid and labeling method for globefish trace amount. The labeling method comprises the following steps of: mixing and stirring 1-3 parts of ultra-fine iron powder and 1-1.5 parts of honey in parts by weight; sucking labeling mixed liquor by using an injector, and then injecting the labeling liquor to the specific injection position of a globefish to be labeled, wherein the injection position of the globefish to be labeled is selected according to different globefishes, and the part of the root of the pectoral fin, subcutaneous head, dorsal fin base, and the like can be used as the injection position; and determining whether the globefish is labeled by using a detector. The raw material of labeling mixed liquor has the advantages of simple composition, stable chemical property, easy availability and cheap price, high labeling speed as well as suitability for mass production.

Owner:DALIAN FUGU AQUATIC PROD

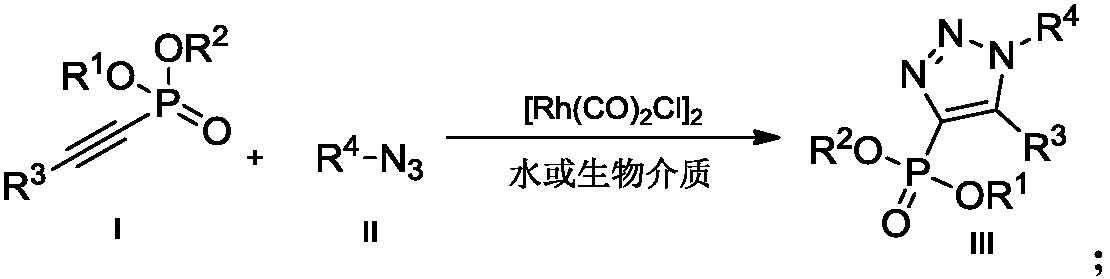

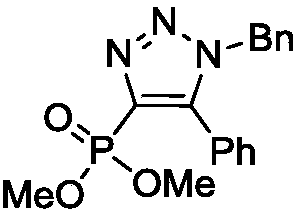

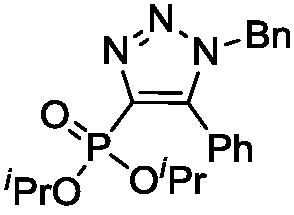

Method for preparing 4-phosphoryl-1,4,5-tri-substituted 1,2,3-triazole in water phase or biomedium

ActiveCN108558945AMild reaction conditionsHigh reaction conditionsGroup 5/15 element organic compoundsOrganic synthesisPhosphate

The invention belongs to the technical field of organic synthesis, and provides a method for preparing 4-phosphoryl-1,4,5-tri-substituted 1,2,3-triazole in a water phase or biomedium. In the water phase or biomedium, under the action of a catalyst tetracarbonyl dichloride rhodium dimer [Rh(CO)2Cl]2, an alkynyl phosphate compound and nitrine are catalyzed to prepare the 4-phosphoryl-1,4,5-tri-substituted 1,2,3-triazole. The preparation method of the 4-phosphoryl-1,4,5-tri-substituted 1,2,3-triazole is mild in reaction conditions, and the product yield is not less than 71 percent. The reaction conditions of the preparation method are mild; water is used as a solvent, so that the method is environmentally friendly, high in reaction efficiency and more suitable for large-scale production requirements; the prepared 4-phosphoryl-1,4,5-tri-substituted 1,2,3-triazole compound has potential physiological activity.

Owner:DALIAN UNIV OF TECH

A kind of preparation method of alkynyl phosphate

ActiveCN109180725BBiologically activeSimple reaction conditionsGroup 5/15 element organic compoundsPhosphoric Acid EstersPtru catalyst

The invention belongs to the technical field of organic synthesis, and provides a method for preparing novel alkynyl phosphate. The method comprises the following steps: in an organic solvent, under the action of a silver nitrate catalyst, using 1.2 equivalent amount of N-bromo-succinimide as a brominating agent, under room temperature condition, performing in-situ formation of an alkynyl bromide,adding copper sulfate pentahydrate as a catalyst, taking 1,10-phenanthroline as a ligand, reacting 2 equivalent amount of potash in toluene at the temperature of 65 DEG C for 12-24 hours, and obtaining the alkynyl phosphate compounds with the yield being 75%-86%. The method prepares the alkynyl phosphate compound, and the product yield is not less than 75%. The preparation method has simple reaction conditions and high reaction efficiency, and is more suitable for large-scale production requirements, and the prepared alkynyl phosphate compound has potential physiological activity and can be converted into various heterocyclic compounds.

Owner:DALIAN UNIV OF TECH

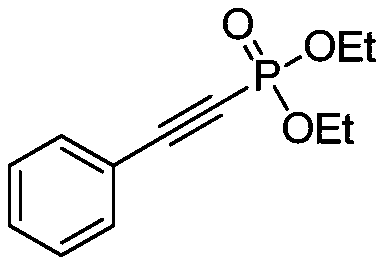

Fluorescent mesoporous silicon oxide nanomaterial and preparation method and application thereof

InactiveCN102295926BGood dispersionUniform pore sizePharmaceutical non-active ingredientsIn-vivo testing preparationsFluorescenceSilicon oxide

The invention discloses a fluorescent mesoporous silicon oxide nanomaterial and a preparation method and an application thereof. The material is characterized in that a silicon-rich microdomain formed by silicon clusters or silicon quantum dots is embedded in a framework of mesoporous silicon oxide. The preparation method of the material comprises the following steps: adding a water-soluble surfactant and a hydrolyst in water, agitating at 4-60 DEG C and dissolving fully; adding hypoxic silicate ester in the system, continuing agitating for 1-48 h, centrifuging, washing and drying; and calcining in inert atmosphere or vacuum condition to obtain a precursor material. As the fluorescent mesoporous silicon oxide nanomaterial prepared by the preparation method disclosed by the invention has good dispersibility, uniform nanometer size and adjustable aperture and adjustable luminescent performance, the fluorescent mesoporous silicon oxide nanomaterial integrates porous structure and fluorescence function, has double functions of drug loading and conveying and synchronous fluorescence imaging, and has potential application value in synchronous diagnosis and treatment of diseases.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A preparation method of in-situ mgo dispersion strengthened ultrafine-grained al-mg alloy

The invention belongs to the field of powder metallurgy, and specifically relates to a preparation method for in-situ generation of MgO dispersion-strengthened ultra-fine-grained Al-Mg alloy. The technical solution of the present invention is as follows: it includes the following steps: weighing Al powder and Mg powder, wherein the atomic ratio of solute Mg atoms in the alloy is 0-8at.%; ball milling, first using a planetary ball mill to fully mix at low operating speed powder for 6 hours, with a rotation speed of 180-220 rpm; then ball mill the mixed powder for 36 hours at a high operating speed, with a rotation speed of 480-520 rpm, with no interruption during high-energy ball milling; passivation treatment, and pressing into a powder body ; Heating to 500°C, and then holding at 500°C for 2 minutes. After the heat preservation is completed, immediately move the heated powder blank into the preheated extrusion die and hot-extrude the powder blank into a hot extrusion rod with a diameter of 6mm; heat treatment. The alloy prepared by the invention has the advantages of low density, high strength, high elastic modulus, ultra-fine microstructure and clean particle interface.

Owner:NORTHEASTERN UNIV LIAONING

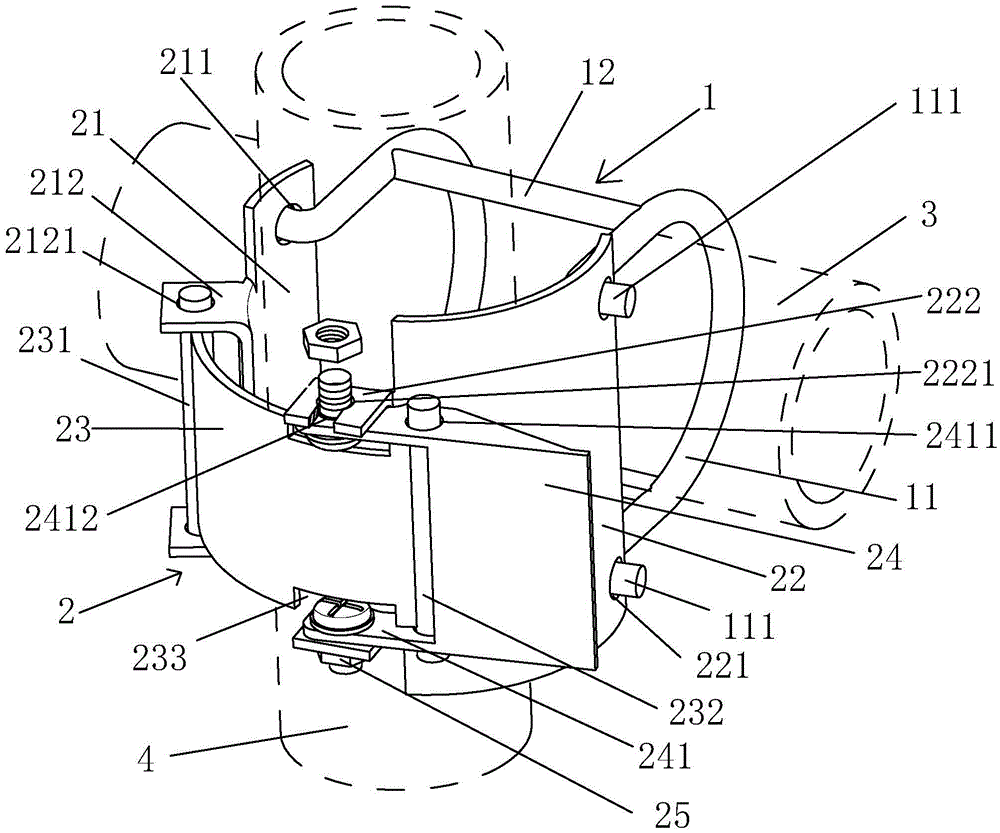

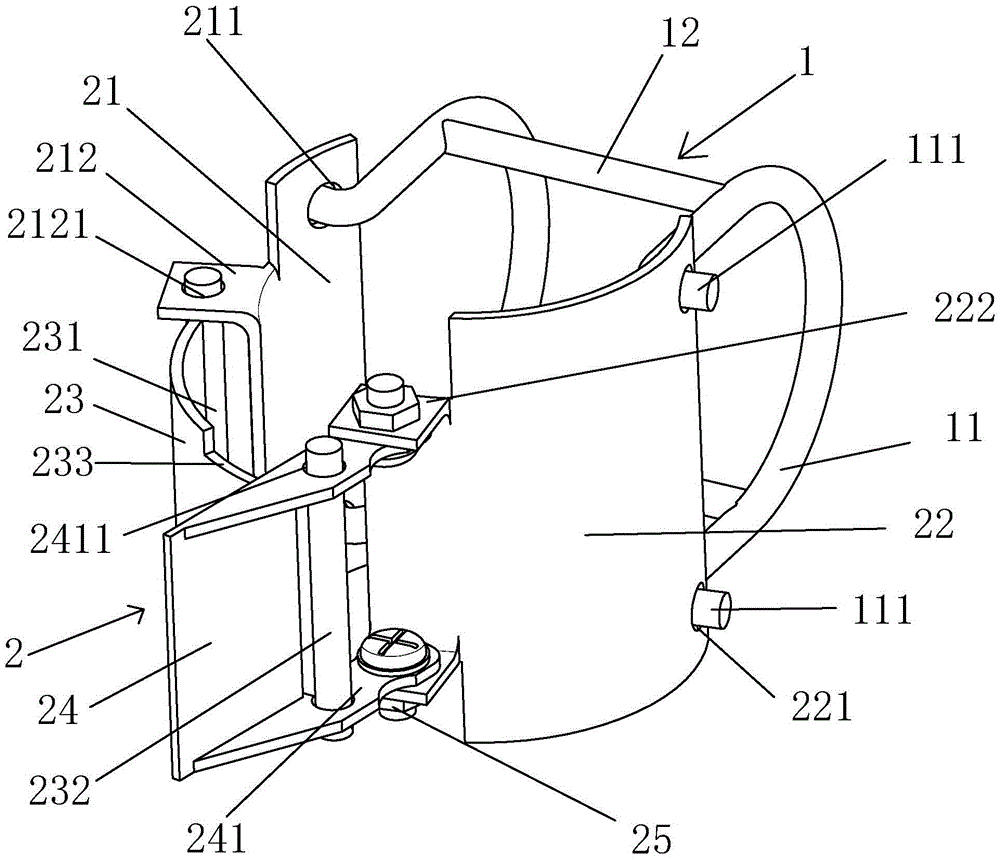

Orthogonal stacked steel pipe lever tensioning device

ActiveCN104631814BEasy to fixEasy to install and disassembleScaffold connectionsStructural engineering

The invention belongs to the technical field of fastening devices for steel pipes in building construction, and relates to a tensioning type fastening device for orthographically-overlapped steel pipe levers. The tensioning type fastening device comprises a clamp and a tensioning mechanism, and the clamp is connected with the tensioning mechanism. The tensioning type fastening device is characterized in that the tensioning mechanism is composed of a short tensioning plate, a long tensioning plate, a connecting plate, a pull buckle and hinge pieces, first connecting holes are formed in one side edge of the short tensioning plate, first connecting seats are arranged on the other side edge of the short tensioning plate, and first hinge holes are formed in the first connecting seats; second connecting holes are formed in one side edge of the long tensioning plate, second connecting seats are arranged on the other side edge of the long tensioning plate, and second hinge holes are formed in the second connecting seats; pull buckle feet are arranged on the two sides of the pull buckle, and third hinge holes and fourth hinge holes are formed in the pull buckle feet; a first hinge column and a second hinge column are arranged at the two ends of the connecting plate, the first hinge column is arranged in the first hinge holes in a pivotal mode, the second hinge column is arranged in the third hinge holes in a pivotal mode, and the second hinge holes are connected with the fourth hinge holes through the hinge pieces. Mounting and dismounting are convenient, work efficiency is improved, fixing is firm, and use is safe. Manufacturing is convenient, and cost is low.

Owner:JIANGSU YONGFENG CONSTR GRP

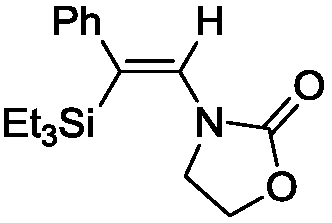

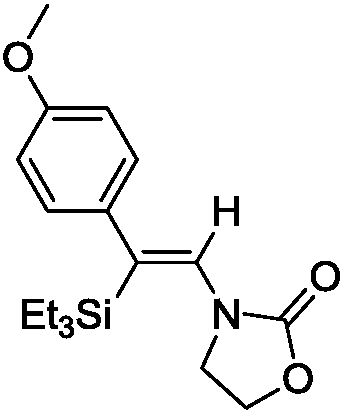

Method for preparing novel vinyl silicon compound

InactiveCN108586512AMild reaction conditionsImprove reaction efficiencySilicon organic compoundsOrganic solventOrganic synthesis

The invention belongs to the technical field of organic synthesis and provides a method for preparing a novel vinyl silicon compound. The method comprises the following step: in an organic solvent, catalyzing a ynamine compound and an organosilane compound under the action of a tetracarbonyl rhodium dichloride dimer [Rh(CO)2Cl]2 catalyst, thereby obtaining a (Z)-beta-vinyl silicon compound. The method for preparing the (Z)-beta-vinyl silicon compound is mild in reaction condition, and the product yield is not less than 65%. The method is mild in reaction condition, green and high in reaction efficiency, and is relatively well applicable to on-scale production requirements, and the prepared (Z)-beta-vinyl silicon compound can be converted into multiple medicine intermediates.

Owner:DALIAN UNIV OF TECH

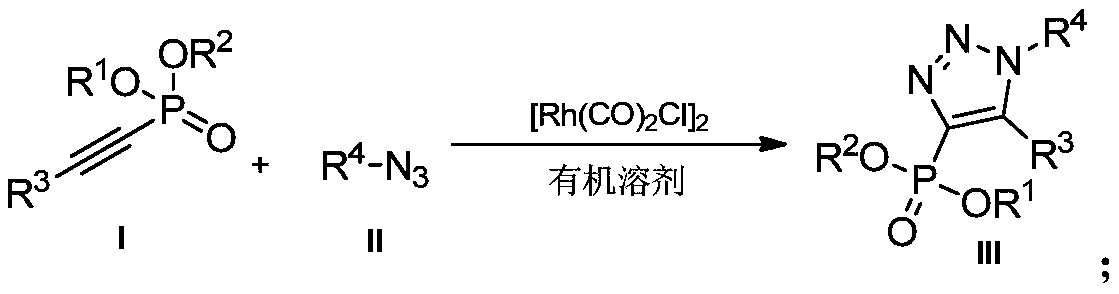

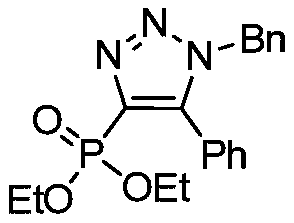

A kind of preparation method of 4-phosphoryl-1,4,5-trisubstituted 1,2,3-triazole

ActiveCN108558944BMild reaction conditionsReaction conditions greenGroup 5/15 element organic compoundsDimerPhosphoric Acid Esters

The invention belongs to the technical field of organic synthesis, and provides a preparation method of novel 4-phosphoryl-1, 4, 5-trisubstituted 1, 2, 3-triazole. According to the preparation method,in an organic solvent, under the action of a tetracarbonyl rhodium dichloride dimer [Rh(CO)2Cl]2 catalyst, an alkynyl phosphate compound and azide are catalyzed to prepare the 4-phosphoryl-1, 4, 5-trisubstituted 1, 2, 3-triazole. By the preparation method of the 4-phosphoryl-1, 4, 5-trisubstituted 1, 2, 3-triazole product, provided by the invention, a reaction condition is mild and the product yield is not lower than 67%. With the preparation method, the reaction condition is mild and environmentally friendly, the reaction efficiency is high, a large-scale production requirement is met better, and the prepared 4-phosphoryl-1, 4, 5-trisubstituted 1, 2, 3-triazole compound has potential physiological activity.

Owner:DALIAN UNIV OF TECH

Labeling method and labeling liquid for globefish trace amount

InactiveCN101703021BSimple compositionChemically stableClimate change adaptationPisciculture and aquariaPhysical chemistryTrace Amounts

The invention discloses a labeling liquid and labeling method for globefish trace amount. The labeling method comprises the following steps of: mixing and stirring 1-3 parts of ultra-fine iron powder and 1-1.5 parts of honey in parts by weight; sucking labeling mixed liquor by using an injector, and then injecting the labeling liquor to the specific injection position of a globefish to be labeled, wherein the injection position of the globefish to be labeled is selected according to different globefishes, and the part of the root of the pectoral fin, subcutaneous head, dorsal fin base, and the like can be used as the injection position; and determining whether the globefish is labeled by using a detector. The raw material of labeling mixed liquor has the advantages of simple composition, stable chemical property, easy availability and cheap price, high labeling speed as well as suitability for mass production.

Owner:DALIAN FUGU AQUATIC PROD

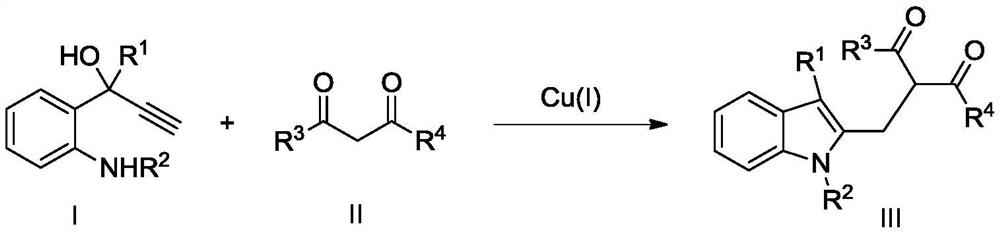

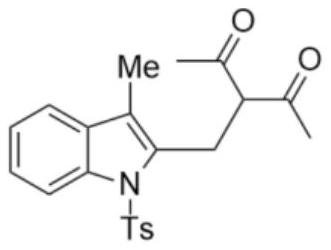

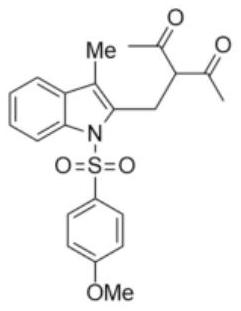

A kind of preparation method of 2,3-disubstituted indole compounds

ActiveCN109851548BMild reaction conditionsImprove reaction efficiencyOrganic chemistryPtru catalystOrganic synthesis

The invention belongs to the technical field of organic synthesis, and relates to a preparation method of 2,3-disubstituted indole compounds. In an organic solvent, under the condition of monovalent copper as a catalyst, the anilines substituted by ortho propargyl alcohol are catalyzed. The compound undergoes cyclization series reaction with dicarbonyl compounds to prepare 2,3-disubstituted indole compounds. In the present invention, a cheap copper catalyst is used to prepare 2,3-disubstituted indole compounds, the reaction hardly generates other by-products, and the product yield is not lower than 62%. The reaction conditions of the preparation method are mild, green, and the reaction efficiency is high, which is more suitable for large-scale production requirements, and the prepared 2,3-disubstituted indole compounds have potential physiological activities.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com