Rotating-tube-type multi-tube pulse detonation engine

A detonation engine and pulse detonation technology, applied in mechanical equipment, intermittent injection devices, etc., can solve the problems of large heat load of the detonation tube, inconvenient use, difficulty in ignition coordination and control, etc., to achieve good heat dissipation and ensure relative position, increased reliability, and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

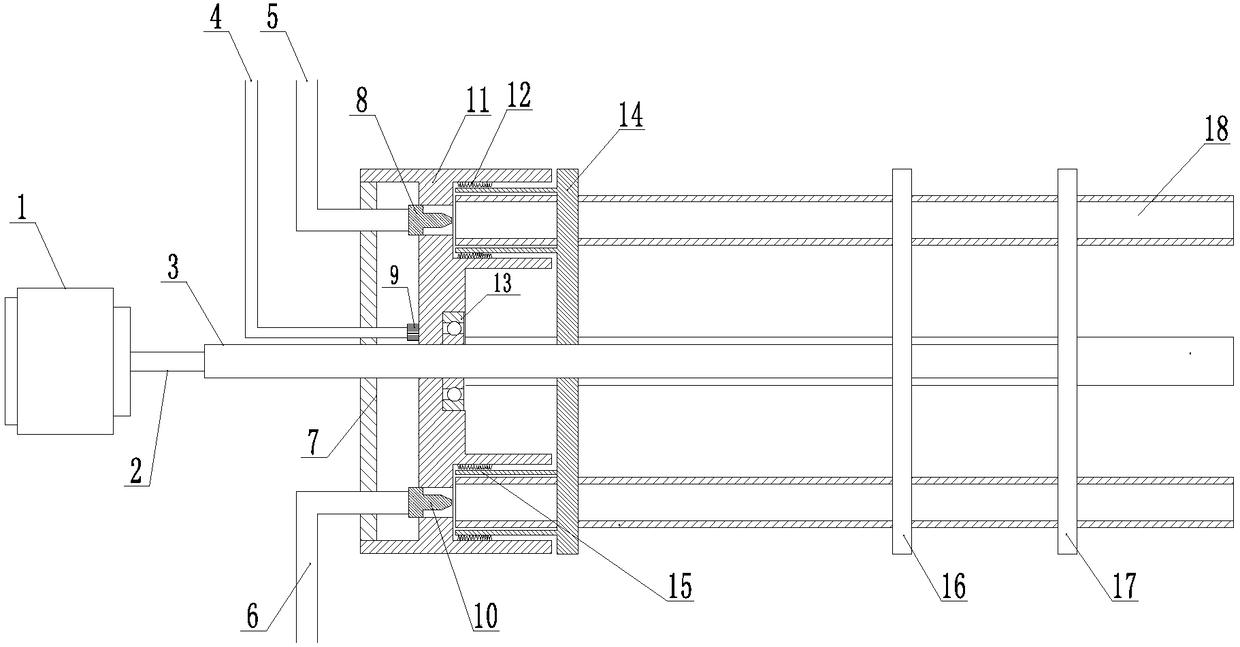

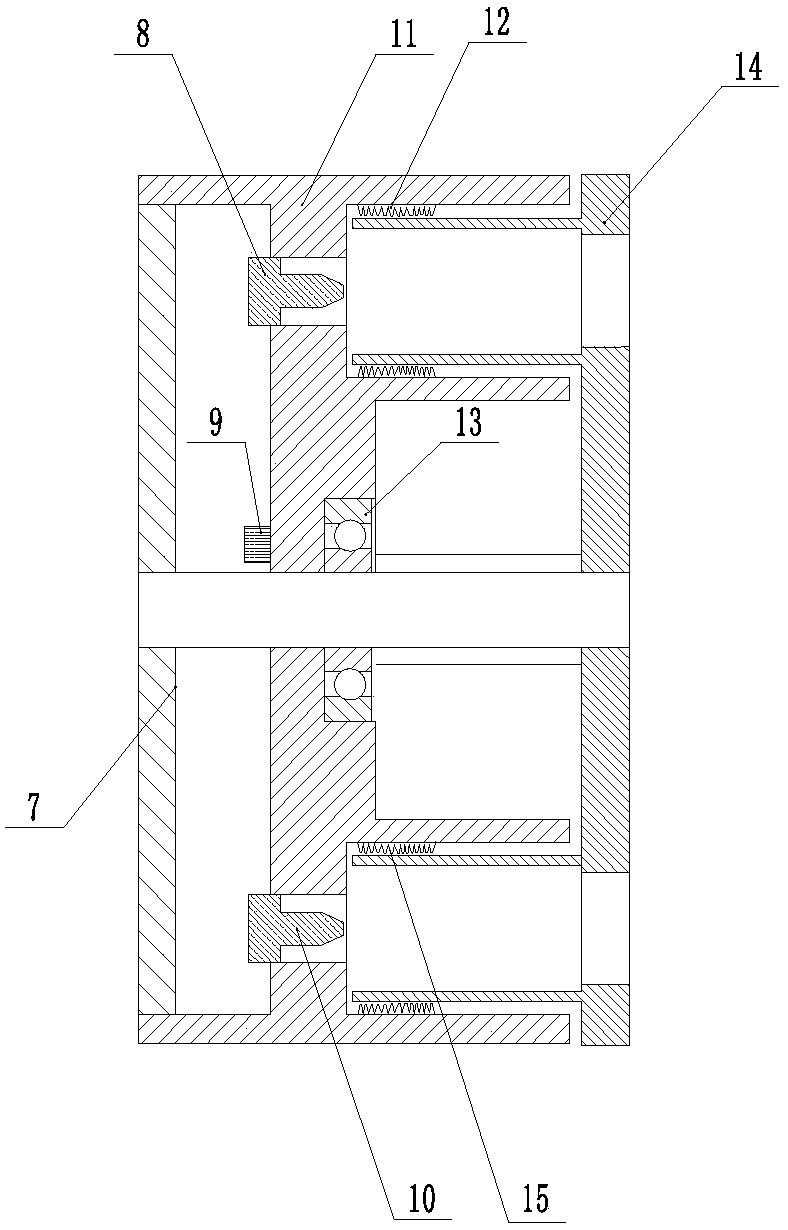

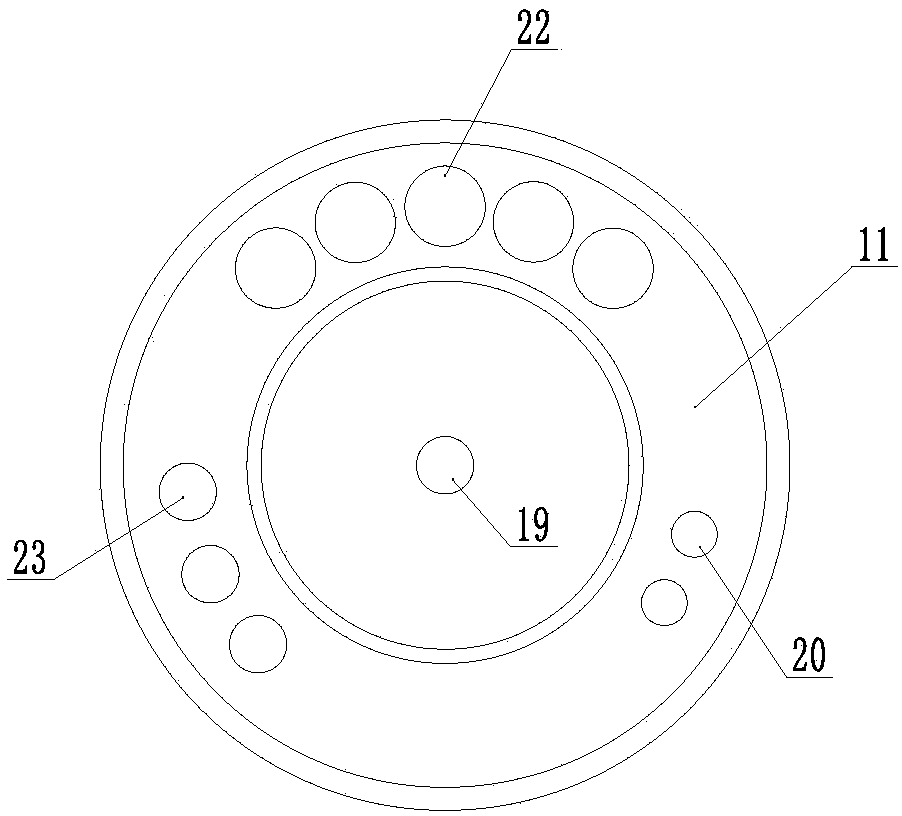

[0029] Such as Figure 1-Figure 5 As shown, a rotary tube type multi-tube pulse detonation engine includes a drive motor 1, a detonation engine main shaft 3 coaxially fixedly connected to the output shaft 2 of the drive motor 1, and at least two detonation tubes 18. The detonation The axis of the tube 18 is arranged parallel to the axis of the detonation engine main shaft 3, the detonation tubes 18 are radially and evenly distributed along the circumference of the detonation engine main shaft 3, and the axis of the detonation tube 18 reaches the detonation engine The spindle axis 3 has the same distance, and also includes a first detonation tube connection plate 16 for connecting the detonation tube 18, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com